8ft By 5 Ft Honeycomb Aluminum Sheets - Aluminium Sheet, Plate, and Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

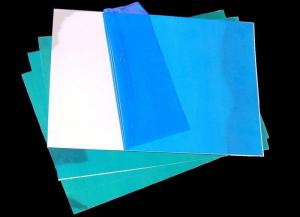

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How does the reflective film stick to the aluminum plate?

- Put the plate clean, dry, reflective film a head from the aluminum back 2CM at the beginning attached to the aluminum plate, wrapping, pull to the front, back and side brush paper hanging tear reflective film side with the hanging brush to the aluminum paste, try to avoid bubbles.

- Q: what is aluminum pigment paint in the scratch cards of lottory?is it metalic or organic sabstance like latex?

- Yes its aluminium metal. Finely divided aluminium powder is dispersed in a polymer resin as used for paint.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior walls. They are lightweight, durable, and resistant to weathering and corrosion, making them suitable for facades. Aluminum sheets can be easily shaped and offer design flexibility. They also have good thermal properties and can be coated or finished in various ways to enhance their appearance and performance. However, they may not provide the same insulation as traditional materials, so additional insulation may be required.</p>

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically consists of 99.5% pure aluminum with trace amounts of other elements such as iron and silicon.

- Q: And isn't aluminum extremely bad for ones health?

- it's okorder

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- The six is the beginning of aluminum silicon alloy is 6061, the United States, 6063, 6082, (a less plate plate is also in many aspects at the beginning of the seven section), is al mg Zn Cu alloy, 7075, 7050, 7475, also belong to the aviation aluminum, also called super hard at the beginning of the eight other series, is currently used in many aspects of the cap, usually thin. As for the number of each brand on behalf of what meaning, I answered another netizen's questions, you know in Baidu search "aluminum plate 1060-H24 what does it mean", you can see my answer

- Q: Are aluminum sheets suitable for aerospace fuel tanks?

- Aerospace fuel tanks can indeed utilize aluminum sheets. In the aerospace industry, aluminum is widely employed because of its lightweight yet robust characteristics. Its strength-to-weight ratio is commendable, rendering it an ideal choice for fuel tanks that must endure the forces of flight while minimizing the aircraft's overall weight. Moreover, aluminum's resistance to corrosion is pivotal for aerospace fuel tanks, considering their exposure to diverse fuels and environmental conditions. Furthermore, aluminum's ease of fabrication and widespread availability make it a cost-efficient option for aerospace applications. In summary, aluminum sheets are a fitting material for aerospace fuel tanks due to their strength, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: What are the different methods of surface laminating aluminum sheets?

- There are several methods of surface laminating aluminum sheets, including adhesive bonding, roll bonding, and extrusion. Adhesive bonding involves using an adhesive to attach a layer of material onto the surface of the aluminum sheet. Roll bonding involves passing the aluminum sheet through a set of rollers, which bond a layer of material onto the surface. Extrusion involves forcing the aluminum sheet through a die, which applies a layer of material onto the surface. These methods provide different options for achieving surface lamination based on the desired application and requirements.

- Q: Can aluminum sheets be used for protective barriers?

- Yes, aluminum sheets can be used for protective barriers. Aluminum is a lightweight and durable material that offers good resistance against impact, corrosion, and fire. It can be easily fabricated into sheets, making it suitable for various applications such as protective barriers in construction, transportation, and industrial settings.

- Q: Alumina is the protective coating that covers aluminum when exposed to oxygen. It's actually corroded aluminum that prevents the aluminum from continuously corroding.What I didn't know until recently was that alumina is an electrical insulator. If that's the case why then isn't aluminum an insulator if one is trying to pass current along its surface?

- Corroded aluminum is not the same substance as rust is not the same as iron. Iron is simply Fe, rust is Fe2O3 if I am correct. So the alumina is not the same as aluminum. Just because something has an element in it doesn't mean it has the properties of the material, or is even similar to that element in anyway. Glass is conductive when its molten, but not when its cool and hard, like windows. So unless what you are dealing with is exactly the same thing, you can't assume anything about it, generally. EDIT: Aluminum is Al, alumina is Al2O3. Alumina is an oxide, aluminum is a pure element, they aren't the same so they can have different properties. As for being an insulator, the layer of alumina is usually so thin it only adds a small amount of resistance to a circuit. If you had a block made of pure alumina and you tried to run current through it it would add lots of resistance or so much there would be virtually no flow.

Send your message to us

8ft By 5 Ft Honeycomb Aluminum Sheets - Aluminium Sheet, Plate, and Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords