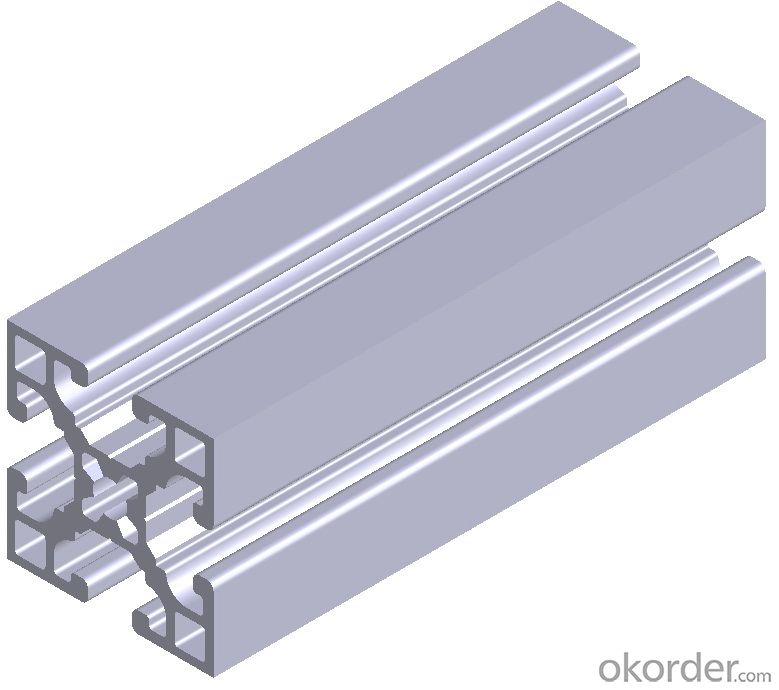

Structural Aluminum Extrusion Profiles - Aluminium S-Profile for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium S-profile for Building Constructions Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium S-profile for Building Constructions:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of theAluminium S-profile for Building Constructions:

Aluminium S-profile for Building Constructions Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do aluminum profiles provide structural stability?

- Structural stability is achieved through the inherent properties and design characteristics of aluminum profiles. The lightweight and strong nature of aluminum makes it an ideal material for constructing different structures. Its high strength-to-weight ratio allows it to support heavy loads while keeping the overall weight of the structure to a minimum. Moreover, aluminum profiles can be designed in various shapes and cross-sections, enabling optimal load distribution and maintaining structural integrity. These profiles can be extruded into shapes like I-beams, T-sections, or rectangular profiles, enhancing the strength and rigidity of the structure. Additionally, aluminum exhibits excellent resistance to corrosion, ensuring the durability and structural soundness of the profiles even in harsh environments. This corrosion resistance eliminates the need for frequent maintenance and extends the lifespan of the structure. Furthermore, aluminum profiles are easily fabricated and assembled, making construction efficient and cost-effective. They can be cut, drilled, welded, or fastened together to create complex structures with precise dimensions. This flexibility in fabrication and assembly allows the profiles to be customized to meet specific design requirements and provide optimal structural stability. In conclusion, aluminum profiles offer structural stability due to their lightweight strength, versatile design options, corrosion resistance, and ease of fabrication and assembly. These properties make aluminum profiles a preferred choice in various industries, including construction, transportation, aerospace, and others.

- Q: This question asks for an overview of the typical materials used in the production of aluminum profiles.

- <p>Aluminum profiles are commonly made from various aluminum alloys, each with specific properties suited for different applications. The most common materials include 6063 aluminum alloy, known for its good mechanical properties and corrosion resistance, making it ideal for construction and industrial applications. 6061 aluminum alloy is also widely used due to its high strength-to-weight ratio and is often found in aerospace and automotive industries. Other alloys such as 6082 and 7075 are used for their superior strength and are common in heavy-duty applications. Each alloy is chosen based on the required strength, weight, and resistance to environmental factors for the intended use of the aluminum profile.</p>

- Q: Shenzhen aluminum profile manufacturers which good?

- How to choose the industrial aluminum profiles, this problem for the just contact with industrial aluminum profile friends, is really a serious problem to consider.That selection of industrial aluminum manufacturers is not good, money, goods is not good, he can give you redo is OK, but also take time; meet industrial aluminum manufacturers some black, and you may be wrangling, that egg pain.

- Q: What is the difference between 6063-T5 and 6061-T6 aluminum profiles?

- T6 treatment of aluminum alloy is solid solution treatment and artificial aging treatment. Aluminum alloy with different components can be treated with T6 as the solution is treated by heat treatment. However, the specific technological parameters vary according to the composition, such as solid solution temperature and aging temperature. 6061 of the T6 process is: solid solution treatment temperature of 530 degrees, artificial aging to make T6, the state is plate 160 degrees, bar and 80 thickness above plate 175 degrees.

- Q: and I know the meaning of 125MN is 12500 tons. I want to know if 125MN is a English an abbreviation of the word, if it is, then what is he, if he is not that what is the meaning?

- MN is an international unit, said the bull"125MN's extruder is 12500T's extruderBloomberg metal Forum

- Q: Aluminum profiles and plastic doors and windows which good, what market?

- Always feel that aluminum is better to do it?! As far as I know, aluminum is more wear resistant, more resistant to corrosion, and it is not easily deformed. There is an aluminum company in Shanghai. I think it's not bad. I bought it there several times. This is what my family uses

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: or what is the difference between the national standard aluminum profile and the European standard aluminum profile, preferably with pictures? Thank you

- The difference between national standard aluminum profile and European standard aluminum profile:Cross section four angles are different: national standard, four angles are right angle, European standard four angles have radian;The shape of the groove is not the same: GB groove is square, European standard slot is obtrapezoid;The rice is different in weight: the national standard is relatively heavy, and the European standard is relatively light.The fittings and installation methods used are different.

- Q: Are aluminum profiles suitable for use in furniture fittings and accessories?

- Yes, aluminum profiles are suitable for use in furniture fittings and accessories. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for various furniture applications. Additionally, aluminum profiles can be easily fabricated into different shapes and designs, allowing for versatility in furniture design.

- Q: Can aluminum profiles be used in the production of automotive interiors?

- Yes, aluminum profiles can be used in the production of automotive interiors. Aluminum is a lightweight and durable material that offers numerous advantages for automotive applications. It is highly resistant to corrosion, which is essential for withstanding the harsh conditions within vehicles. Aluminum profiles can be used to create various components in automotive interiors, such as door panels, instrument panels, seat frames, and trim pieces. Additionally, aluminum profiles can be easily formed and shaped to meet specific design requirements, allowing for flexibility in automotive interior design. The use of aluminum profiles in automotive interiors can help reduce the overall weight of the vehicle, resulting in improved fuel efficiency and reduced emissions.

Send your message to us

Structural Aluminum Extrusion Profiles - Aluminium S-Profile for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords