Powder Coated Aluminum Remelting Coil Like Aluminium Ingot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

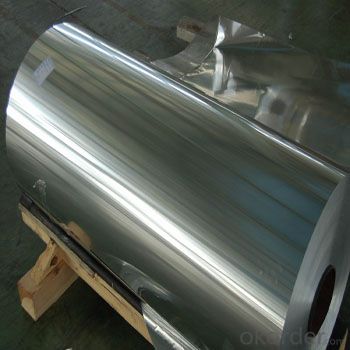

ALUMINIUM FOIL

ALLOY:AA1***

TEMPER: F O H14 H16 H18 H22 H24 H26

THICKNESS: 0.006MM-0.20MM

WIDTH: 200MM-1600MM

COATING: HSL/PRIMER

STANDAR: GB/T 3198-2003

2.Application

Our Remelting aluminium coil is the same as aluminium ingot, and the price is cheaper.

3.Why you can truct us?

We promise the best quality and price!

4.Pictures

5.FAQ

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

4)What can you do if you have other quastions?

You can contact us freely at any time!

- Q: Are there any restrictions on the coil surface quality of aluminum coils?

- Yes, there are certain restrictions on the coil surface quality of aluminum coils. The surface quality of aluminum coils is an important factor as it affects the overall performance and appearance of the final product. Some of the restrictions on the coil surface quality include: 1. Surface defects: Aluminum coils should be free from any visible defects such as scratches, pits, dents, or cracks. These defects can impact the functionality of the coil and can also affect the aesthetics of the finished product. 2. Surface roughness: The surface of aluminum coils should have a uniform and smooth finish. Excessive roughness can lead to poor adhesion of coatings or paints, and can also affect the ability of the coil to be formed into desired shapes. 3. Surface cleanliness: Aluminum coils should be free from any contaminants such as dirt, oil, or grease. Contaminants can interfere with subsequent processes like painting, coating, or bonding, and can also impact the overall performance of the coil. 4. Surface oxidation: Aluminum is prone to oxidation, which can result in the formation of a thin layer of oxide on the surface. While a certain level of oxidation is acceptable, excessive oxidation can lead to poor adhesion of coatings or paints, and can also affect the corrosion resistance of the coil. 5. Surface flatness: Aluminum coils should have a flat and even surface. Any waviness or unevenness can cause issues during subsequent manufacturing processes like stamping, bending, or rolling. These restrictions on coil surface quality are important to ensure that the aluminum coils meet the desired specifications and can be used effectively in various applications such as automotive, construction, packaging, and electrical industries.

- Q: The company wants to produce an aluminum coil production line, which is better for large aluminium smelting equipment?

- Dongpu heat well, they have the qualification certificate issued by the state kiln construction, as far as I know, their melting furnace Aluminum Alloy 'plan is very good, and the operation is simple and safe, feel good, can be wiped off

- Q: How do aluminum coils perform in high-temperature applications?

- Aluminum coils perform well in high-temperature applications due to their excellent heat conductivity and resistance to corrosion. They can efficiently dissipate heat and maintain their structural integrity, making them suitable for various industries such as automotive, aerospace, and HVAC systems.

- Q: Are aluminum coils available in custom sizes?

- Yes, aluminum coils are available in custom sizes.

- Q: What are the various applications and purposes for which aluminum coils are utilized?

- <p>Aluminum coils have a wide range of applications due to their lightweight, corrosion resistance, and malleability. They are commonly used in construction for roofing and siding, in the automotive industry for car parts and body panels, in the packaging industry for cans and foils, and in electrical applications for wiring and transformers. Aluminum coils are also used in the manufacturing of heat exchangers, cooking utensils, and various consumer products. Their versatility makes them an essential material in many industries.</p>

- Q: Can aluminum coils be used in high-humidity environments?

- Yes, aluminum coils can be used in high-humidity environments. Aluminum is a corrosion-resistant metal, and when properly protected with coatings or finishes, it can withstand high levels of humidity without rusting or deteriorating.

- Q: Are aluminum coils suitable for food processing and packaging?

- Aluminum coils are indeed suitable for food processing and packaging, as aluminum is a highly versatile metal that offers numerous benefits to the food industry. Firstly, it possesses exceptional thermal conductivity, enabling efficient heat transfer during food processing and cooking. This characteristic guarantees even cooking and prevents the formation of hot spots or uneven heating. Moreover, aluminum proves to be an exceedingly corrosion-resistant material, a crucial aspect for food packaging. It effectively shields the food from external elements such as moisture, oxygen, and light, all of which can degrade the quality and freshness of the product. Aluminum coils can be effortlessly molded into various shapes and sizes, making them an ideal choice for packaging a wide range of food products, including cans, pouches, trays, and lids. In addition to these advantages, aluminum is a lightweight material that facilitates convenient transportation and reduces energy consumption during distribution. Its recyclability feature further contributes to minimizing the environmental impact of food packaging. In summary, aluminum coils are exceptionally well-suited for food processing and packaging due to their exceptional thermal conductivity, corrosion resistance, versatility, lightweight nature, and recyclability.

- Q: I have aluminum windows that have to be replaced due to bad thermopanes - there is accumulated grime and humidity in between the panes. Is it possible to buy individual custom-sized replacements or do I have to get all new windows and frames? Any referrals would be helpful.

- New windows aren't that expensive. They are plastic now because they insulate better. You just cut around the frame with a skill saw and leave the flange in place. pull out the old window and nail or screw the new frome on the outside of the wall use caulking and new trim boards. Just do one at a time as you can afford it.

- Q: I know this question is not so bright, but I am very curious why do we recycle aluminum cans? Is it that they are not biodegradable?

- Heck yeah. Even an old school, smoke-belching industrialist would recycle *metal*. That's always been true. Why did people suddenly stop recycling metals? Have you PRICED metals lately? Aluminum is over a buck a pound, copper is $3 a pound, steel is over $200 a ton.

- Q: Is it possible to utilize aluminum coils in the packaging of food products?

- <p>Yes, aluminum coils can be used for food packaging. They are commonly used in the production of aluminum foil, which is a popular material for food packaging due to its properties such as light weight, barrier to light and oxygen, and recyclability. Aluminum foil is used to wrap food, line baking sheets, and create containers, providing a protective barrier that helps to preserve freshness and extend shelf life. However, it's important to ensure that the aluminum used meets food-grade standards to avoid any health risks.</p>

Send your message to us

Powder Coated Aluminum Remelting Coil Like Aluminium Ingot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords