Customized Colorful Aluminum Profiles - Aluminium Foil Stocks Warehouse Warehouse Price

- Loading Port:

- Shanghai

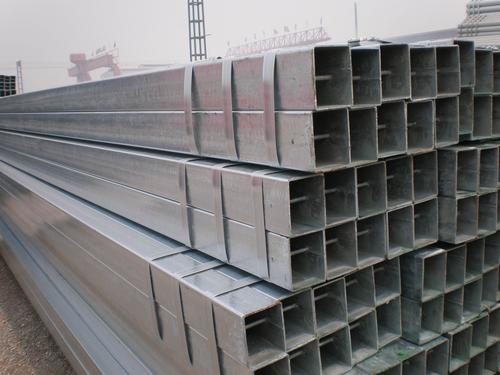

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet and also the other grades are all best-selling in China now,

is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet,

checkered sheet, mirror finish aluminium cold roled and hot rolled

sheet, aluminum casting coil, etc.

- Q: What are the different fastening options available for aluminum profiles?

- Some of the different fastening options available for aluminum profiles include screws, bolts, nuts, rivets, and adhesive bonding.

- Q: how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q: Is it possible to recycle and reuse aluminum profiles?

- <p>Yes, aluminum profiles can be recycled and reused. Recycling aluminum is an efficient and environmentally friendly process, as it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for various applications. The recycling process involves melting the aluminum, which can then be reformed into new profiles without losing its strength or quality. This practice reduces waste and conserves natural resources, contributing to sustainability efforts.</p>

- Q: How can I distinguish aluminum from aluminium oxide or electrophoresis aluminum or spray aluminium material?

- The electrophoretic material looks very textured, very uniform, and full range. Spray paint will not spray in some places, and the color is not as good as electrophoresis.

- Q: This question asks for a list of various interior wall cladding systems that incorporate aluminum profiles.

- <p>Aluminum profiles are versatile and commonly used in interior wall cladding systems due to their durability and aesthetic appeal. Some of the different types include: 1. Aluminum Composite Panels (ACP), which combine two aluminum sheets with a non-aluminum core. 2. Aluminum Insulated Panels, offering thermal insulation properties. 3. Aluminum Curtain Wall Systems, providing a weather-resistant exterior wall. 4. Aluminum Lining Systems, used for decorative purposes and easy maintenance. 5. Aluminum Ceiling Systems, which can also serve as wall cladding in some designs. 6. Aluminum Drywall Systems, which are lightweight and easy to install. Each system has its specific applications and advantages, making aluminum profiles a popular choice in modern architecture and interior design.</p>

- Q: This question asks for guidance on selecting the appropriate aluminum profile for a construction project.

- <p>To choose a suitable aluminum profile for your building project, consider the following: First, assess the structural requirements such as load-bearing capacity and span. Second, consider the aesthetic preferences and the desired finish or color. Third, evaluate the environmental conditions the profile will be exposed to, such as weather resistance and corrosion. Fourth, consult with suppliers or manufacturers for technical specifications and recommendations. Fifth, ensure compliance with building codes and standards. Finally, factor in the cost and availability of the profiles. It's often helpful to consult with engineers or architects who can provide expert advice tailored to your specific project needs.</p>

- Q: Can aluminum profiles be used in the construction industry?

- Yes, aluminum profiles can be used in the construction industry. Aluminum profiles are lightweight, durable, and resistant to corrosion, making them suitable for various applications in construction. They can be used for the fabrication of windows, doors, curtain walls, and structural components such as beams and columns. The versatility and strength of aluminum profiles make them a popular choice in the construction industry.

- Q: The aluminum and Fenglv aluminum material which is better suited for doors and windows

- Al Feng is one of the ten famous material, certainly no problem. But Feng packaging is too thick, high cost. To do the doors and windows of the aluminum used to choose cost-effective, as a special material for the sale of aluminum, I have the following recommendations: 1. The window wheel is good, and the pressed glass should be durable and corrosion resistant. 2. doors and windows sealing performance better, 3. pages to be matched with materials, gauze or rust, and thickness and density better than 4. The cost performance is high, the surface treatment layer of the profile is electrophoresis, and the electrophoresis layer should be thick. 5. The mounting frame needs to be hit to the horizontal line.

- Q: This question asks about the various materials used for insulation purposes when working with aluminum profiles.

- <p>Different types of insulation materials used with aluminum profiles include thermal insulation materials such as polyurethane foam, mineral wool, and polystyrene. These materials help in reducing heat transfer and maintaining temperature control. Additionally, electrical insulation materials like PVC, polyethylene, and silicone rubber are used to prevent electrical conductivity and protect against electrical hazards. Acoustic insulation materials like fiberglass and soundproofing foam are also used to reduce noise transmission through aluminum structures. Each type of insulation serves a specific purpose and is chosen based on the application's requirements.</p>

- Q: What are the weatherproofing properties of aluminum profiles?

- Due to their inherent characteristics and manufacturing processes, aluminum profiles possess excellent weatherproofing properties. This is due to aluminum being a naturally corrosion-resistant material, allowing it to endure exposure to different weather conditions without deteriorating or rusting. It forms a protective layer of oxide on its surface, serving as an additional barrier against moisture and preventing further corrosion. Moreover, various weatherproofing techniques can further enhance aluminum profiles. Anodizing is a common method where the aluminum surface undergoes an electrolytic process to create a thicker and more durable oxide layer. This not only improves weather resistance but also enhances resistance to scratching and wear. Furthermore, aluminum profiles can be coated with protective finishes like powder coating or liquid paint. These coatings not only add aesthetic appeal but also provide an extra layer of protection against UV radiation, moisture, and other weather elements. Powder coating, in particular, offers exceptional durability and resistance to fading, chipping, and cracking. Additionally, aluminum profiles can be designed to incorporate weatherproof features such as gaskets, seals, and thermal breaks. These elements establish a tight seal between the profile and other building components, preventing water infiltration, air leakage, and thermal transfer. They contribute to maintaining a comfortable indoor environment, reducing energy consumption, and enhancing the overall weatherproofing performance of the aluminum profiles. In summary, the weatherproofing properties of aluminum profiles make them a popular choice for a wide range of applications, including windows, doors, curtain walls, roofing systems, and outdoor furniture. Their ability to withstand harsh weather conditions, resistance to corrosion, and availability of protective coatings make them a dependable and long-lasting option for both residential and commercial projects.

Send your message to us

Customized Colorful Aluminum Profiles - Aluminium Foil Stocks Warehouse Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords