Lightweight Aluminum Sheets White - Aluminium Composite Panel PE/PVDF - Good Price - High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

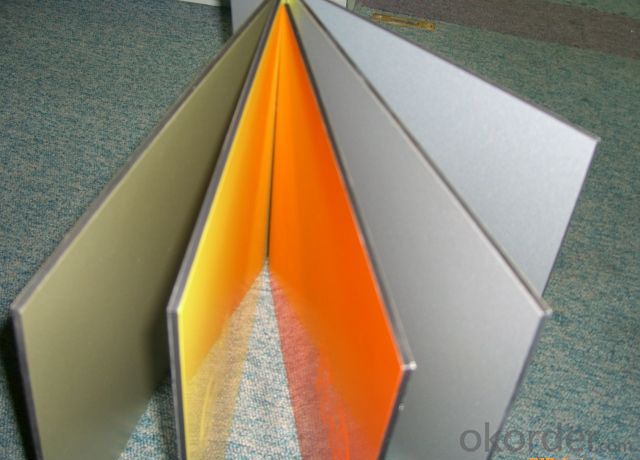

Structure of Aluminium Composite Panel Description:

Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

Main Features of Aluminium Composite Panel:

1) Fireproof and water resistant, excellent heat and sound insulation

2) Excellent surface flatness and smoothness

3) Superior weather, corrosion and pollutant resistance

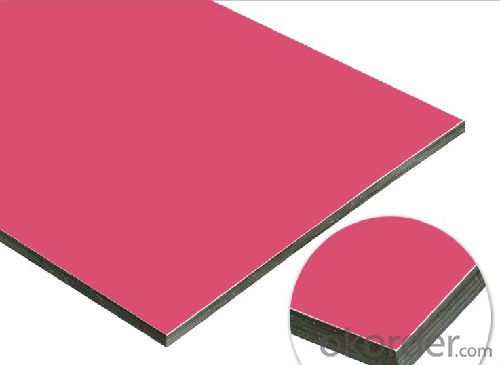

4) Even coating, various colors

5)Super peeling strength

6) Superior impact resistance

7) Lightweight and easy to process

8) Easy to maintain

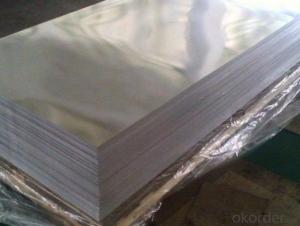

Images of AluminiumComposite Panel:

PE/PVDF Aluminium Composite Panel Specification:

| Width(mm) | 1220 | 1250 | 1500 | |||||

| Length(mm) | 2440 | Or according to customer's request | ||||||

| Panel thickness(mm) | 2 | 3 | 4 | 5 | 6 | |||

| Aluminum thickness(mm) | 0.10 | 0.12 | 0.15 | 0.18 | 0.21 | 0.3 | 0.4 | 0.5 |

| Coating | PVDF | PE | Brush | Mirror | Glossy | Wood and stone texture | ||

FAQ of Aluminium Composite Panel:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the standard dimensions of aluminum sheets?

- The specific industry and application determine the varying standard dimensions of aluminum sheets. However, there are commonly available sizes that are commonly used. For general purposes, aluminum sheets are commonly found in dimensions of 4 feet by 8 feet (1219mm x 2438mm) and 4 feet by 10 feet (1219mm x 3048mm). These dimensions, often referred to as "full sheets," are widely used in construction, manufacturing, and signage industries. Aside from full sheets, smaller sizes of aluminum sheets are also available, such as 2 feet by 4 feet (609mm x 1219mm) and 2 feet by 8 feet (609mm x 2438mm). These smaller sizes are commonly used for DIY projects, crafts, and hobbies. It is important to note that although these dimensions are standard, aluminum sheets can be custom cut to meet specific sizes and shapes for individual project requirements. This provides greater flexibility and versatility across various industries. Ultimately, the choice of aluminum sheet dimensions depends on the specific needs of the project, industry standards, and personal preferences.

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- Aluminum is much cheaper and requires less structure to hold it up. It conducts very well. But is does not work well in homes because the expansion and contraction with heating loosens connections and those to copper wire need special wire nuts/grease

- Q: Can aluminum sheets be easily shaped or bent?

- Indeed, aluminum sheets possess a remarkable capability to be effortlessly molded or flexed. Renowned for its exceptional malleability and ductility, aluminum exhibits a remarkable propensity to be readily fashioned into diverse contours and curves. The manipulation of this versatile metal can be accomplished through an assortment of techniques, encompassing rolling, pressing, and even manual utilization of tools. Given its pliability, aluminum emerges as the preferred choice within industries such as automotive, aerospace, and construction, wherein the fabrication of intricate shapes and bends is a common necessity. Moreover, the lightweight nature and inherent resistance to corrosion further enhance aluminum's suitability for shaping and bending endeavors.

- Q: This question asks about the various color options available for aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors to suit various applications and aesthetic preferences. Common colors include silver (anodized), white, black, and clear (natural). Beyond these, there are also options for colors like red, blue, green, and yellow. Some manufacturers offer custom color matching services for specific projects. Additionally, aluminum sheets can be coated with various finishes such as matte, gloss, or textured, further expanding the color and appearance options. It's important to check with specific suppliers for their available color range as it can vary.</p>

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior siding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It is also resistant to harsh weather conditions and pests, making it a popular choice for many homeowners and builders. However, it is important to ensure proper installation to maximize its benefits and longevity.</p>

- Q: What is the typical corrosion resistance of aluminum sheets?

- Aluminum sheets possess a remarkably high level of corrosion resistance. They naturally generate a protective oxide layer on their surface, which effectively thwarts any further corrosion. This layer of oxide acts as a formidable barrier, preventing moisture and other corrosive elements from accessing the underlying metal. Moreover, aluminum exhibits exceptional resistance to numerous prevalent forms of corrosion, including rusting and pitting. Nonetheless, the corrosion resistance of aluminum can fluctuate depending on several factors, such as the composition of the alloy, the treatment applied to the surface, and exposure to harsh environments. In general, aluminum sheets are renowned for their impressive ability to resist corrosion, rendering them suitable for a vast array of applications across various industries.

- Q: Can aluminum sheets be used for modular construction?

- Absolutely, modular construction can utilize aluminum sheets. Aluminum proves to be an adaptable and lightweight substance that presents numerous advantages for modular construction undertakings. Its resilience, resistance to corrosion, and impressive strength-to-weight ratio render it appropriate for a wide range of structural applications. The malleability of aluminum sheets permits them to be effortlessly fabricated and molded into various forms and dimensions, enabling flexibility in both design and construction. Furthermore, aluminum's recyclability positions it as an environmentally conscious selection for sustainable construction practices. All things considered, aluminum sheets stand as a feasible choice for modular construction given their robustness, durability, and versatility.

- Q: What are the different types of surface treatments available for powder-coated aluminum sheets?

- There are several different types of surface treatments available for powder-coated aluminum sheets. Some of the most common options include anodizing, chemical etching, and mechanical finishing. Anodizing is a process that involves immersing the aluminum sheets in an electrolytic solution and applying an electric current to create a protective oxide layer on the surface. This treatment can enhance the durability and corrosion resistance of the aluminum, as well as provide a decorative finish with a wide range of colors. Chemical etching is another surface treatment method that involves applying a chemical solution to the aluminum sheets to create a textured or patterned surface. This process can be used to create unique designs and improve the aesthetics of the material. Mechanical finishing techniques, such as brushing or polishing, can also be used to enhance the appearance and texture of powder-coated aluminum sheets. Brushing creates a brushed or linear pattern on the surface, while polishing creates a smooth and glossy finish. Additionally, there are specialized surface treatments available for specific applications, such as chromate conversion coating for improved adhesion of adhesives or paints, or clear coatings for added protection against UV radiation. Overall, the choice of surface treatment for powder-coated aluminum sheets depends on the desired aesthetic, functionality, and durability requirements of the application.

- Q: Are 101 aluminum sheets suitable for medical equipment?

- Yes, 101 aluminum sheets are suitable for medical equipment.

Send your message to us

Lightweight Aluminum Sheets White - Aluminium Composite Panel PE/PVDF - Good Price - High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords