Fascia Aluminum Coil for Roofing Application - Aluminum Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

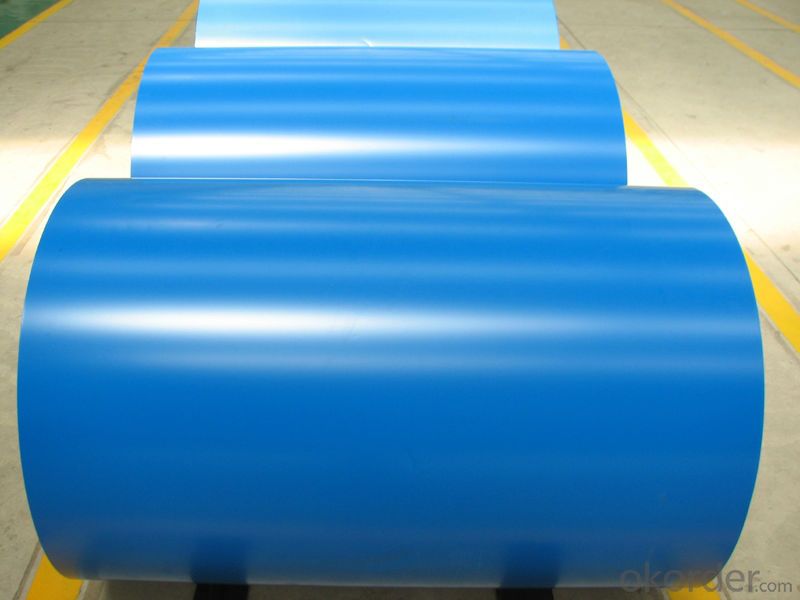

Structure of Aluminium Color Coated Coil for Roofing Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Color Coated Coil for Roofing Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Color Coated Coil for Roofing Application:

Aluminium Color Coated Coil for Roofing Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What precautions should be taken while using tools for handling aluminum coils?

- <p>When handling aluminum coil tools, it's crucial to follow safety measures to prevent accidents. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and closed-toe shoes. Ensure the tools are in good condition and well-maintained. Keep the work area clean and free of debris to avoid slips or trips. Be cautious of sharp edges on the aluminum coils, as they can cause cuts. Use lifting equipment when necessary and never attempt to lift heavy coils manually. Follow all manufacturer guidelines for the safe operation of the tools. Regularly inspect the tools for any signs of wear or damage and replace them as needed.</p>

- Q: Is it possible to utilize aluminum coil in the welding process?

- <p>Yes, aluminum coil can be used for welding. It is commonly used as a filler material in processes like MIG (Metal Inert Gas) welding, where it is fed continuously into the weld pool to create a joint. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need to prevent oxidation. The aluminum coil must be of high quality and clean to ensure a strong, corrosion-resistant weld.</p>

- Q: Is it possible to construct furniture or tables using aluminum coils?

- <p>Yes, aluminum coils can be used to make furniture or tables. Aluminum is a versatile material known for its strength, durability, and lightweight properties. It can be easily bent and shaped into various forms, making it suitable for furniture construction. Aluminum coils can be used to create the frame or support structure of tables and other furniture items. They are also resistant to corrosion and require minimal maintenance, making them a popular choice for outdoor furniture and modern interior designs.</p>

- Q: Can aluminum coils be used in automotive body panels?

- Yes, aluminum coils can be used in automotive body panels. Aluminum is lightweight, corrosion-resistant, and offers excellent strength-to-weight ratio, making it an ideal material for automotive applications. Its use in body panels helps improve fuel efficiency and reduce vehicle weight while maintaining structural integrity.

- Q: show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- Q: Is it possible to utilize aluminum coils in the manufacturing of furniture?

- <p>Yes, aluminum coils can be used to make furniture. Aluminum is known for its strength, durability, and resistance to corrosion, making it an ideal material for furniture construction. It is commonly used in outdoor furniture due to its weather resistance. Aluminum coils can be formed into various shapes and sizes to create frames, legs, and other structural components of furniture. Additionally, aluminum's lightweight nature makes it easy to handle and transport, which is beneficial for both manufacturers and consumers.</p>

- Q: What is the melting point of aluminum coils?

- The melting point of aluminum coils is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Can aluminum coils be used in solar panel systems?

- Yes, aluminum coils can be used in solar panel systems. Aluminum is a popular material choice for solar panel frames and supports due to its lightweight yet strong nature. It is corrosion-resistant, durable, and has excellent thermal conductivity, making it suitable for withstanding harsh weather conditions and efficiently dissipating heat generated by the solar panels. Additionally, aluminum is also highly recyclable, which aligns with the sustainable nature of solar energy systems. Overall, the use of aluminum coils in solar panel systems contributes to their efficiency, longevity, and environmental friendliness.

- Q: How do aluminum coils compare to galvanized steel coils in terms of longevity?

- In terms of longevity, aluminum coils generally have a longer lifespan compared to galvanized steel coils. Aluminum is naturally resistant to corrosion, which means it is less likely to rust or deteriorate over time. This makes aluminum coils a popular choice for outdoor applications, such as in roofing, siding, and HVAC systems, as they can withstand harsh weather conditions without losing their structural integrity. On the other hand, galvanized steel coils are steel coils that have been coated with a layer of zinc to protect against corrosion. While this zinc coating provides some level of protection, it can wear off over time, particularly in areas with high humidity or exposure to saltwater. Once the zinc coating is compromised, the steel underneath becomes susceptible to rust and corrosion, which can significantly reduce the lifespan of galvanized steel coils. Therefore, if longevity is a primary concern, aluminum coils are generally a more durable and long-lasting option compared to galvanized steel coils. However, it is important to consider other factors such as cost, specific application requirements, and maintenance needs before making a final decision.

Send your message to us

Fascia Aluminum Coil for Roofing Application - Aluminum Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords