Hot Rolled Aluminum Coil for Metal Roofing System - Color Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminum Coil for Metal Roofing System

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

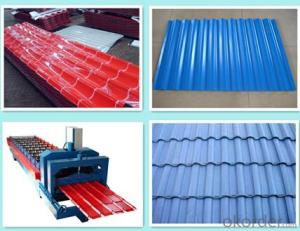

2. Application of Color Coated Aluminum Coil for Metal Roofing System

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil for Metal Roofing System

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

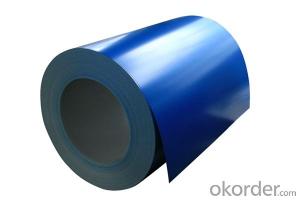

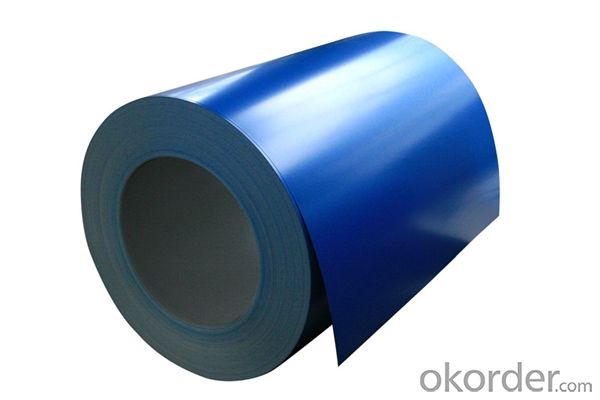

5. Image of Color Coated Aluminum Coil for Metal Roofing System

6. Package and shipping of Color Coated Aluminum Coil for Metal Roofing System

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of coil-perforated aluminum coils?

- Coil-perforated aluminum coils have a wide range of potential applications due to their unique properties and capabilities. Some of the potential applications of these coils are: 1. Architectural Applications: Coil-perforated aluminum coils can be used in architectural projects for facades, cladding, and sunscreens. The perforations allow for the creation of decorative patterns and designs, while also providing functional benefits such as ventilation and light control. 2. Industrial Applications: These coils can be used in various industrial applications such as filtration systems, soundproofing panels, and heat exchangers. The perforations in the aluminum coils allow for the passage of air, sound, and heat, making them suitable for these purposes. 3. Automotive Industry: Coil-perforated aluminum coils can be utilized in the automotive industry for applications such as radiator grilles, speaker covers, and air vents. The perforations in the coils provide functional benefits like airflow, sound transmission, and aesthetic appeal. 4. HVAC Systems: These coils can be employed in heating, ventilation, and air conditioning (HVAC) systems. The perforations in the aluminum coils allow for improved airflow, which helps in efficient temperature regulation and air distribution within buildings. 5. Acoustic Panels: Coil-perforated aluminum coils can be used in the construction of acoustic panels, which are designed to absorb and reduce sound reflections in spaces like auditoriums, theaters, and recording studios. The perforations in the coils aid in sound absorption and diffusion. 6. Lighting Fixtures: These coils can be incorporated into lighting fixtures to create unique lighting effects. The perforations in the aluminum coils allow light to pass through, resulting in visually appealing patterns and designs. 7. Furniture and Decorative Applications: Coil-perforated aluminum coils can be utilized in the manufacturing of furniture, screens, partitions, and decorative elements. The perforations in the coils add a distinctive aesthetic appeal and can create interesting visual effects. Overall, the potential applications of coil-perforated aluminum coils are diverse and encompass various industries, including architecture, automotive, industrial, HVAC, acoustic, lighting, and furniture. The unique properties of these coils, such as their lightweight, durability, and aesthetic customization options, make them a versatile choice for many different uses.

- Q: Are there any environmental benefits to using aluminum coils?

- Yes, there are several environmental benefits to using aluminum coils. Firstly, aluminum is a highly sustainable material as it is 100% recyclable without losing its original properties. This means that using aluminum coils helps reduce the demand for mining and extracting new raw materials, reducing the environmental impact associated with these processes. Additionally, recycling aluminum requires only about 5% of the energy needed to produce primary aluminum, resulting in significant energy savings and reduced greenhouse gas emissions. Moreover, aluminum coils have a longer lifespan compared to other materials commonly used in coils, such as copper or steel. This durability means that fewer coils need to be manufactured and replaced over time, resulting in less waste generation and lower overall environmental impact. Furthermore, aluminum is corrosion-resistant, which eliminates the need for additional treatments or coatings that may contain harmful chemicals. This reduces the release of potentially hazardous substances into the environment during the manufacturing and use of aluminum coils. Lastly, aluminum is lightweight, which contributes to lower transportation costs and energy consumption during distribution. This aspect decreases fuel consumption and associated emissions, reducing the overall carbon footprint of using aluminum coils. Considering these factors, the use of aluminum coils provides significant environmental benefits, including reduced resource extraction, energy conservation, waste reduction, and lower emissions.

- Q: Can aluminum coils be used in high-radiation environments?

- Yes, aluminum coils can be used in high-radiation environments. Aluminum has good radiation resistance and can withstand high levels of radiation without significant degradation or damage. It is commonly used in applications such as nuclear power plants and aerospace industries, where radiation exposure is a concern.

- Q: Can aluminum coils be used in the production of beverage cans?

- Yes, aluminum coils can be used in the production of beverage cans. Aluminum coils are commonly used because aluminum is lightweight, corrosion-resistant, and recyclable, making it an ideal material for beverage cans. The coils are typically formed into can bodies and lids, which are then further processed to create the final beverage cans.

- Q: How do aluminum coils contribute to the insulation properties of products?

- Aluminum coils play a crucial role in enhancing the insulation properties of various products. The use of aluminum coils in insulation systems improves thermal efficiency, minimizes heat transfer, and reduces energy consumption. Firstly, aluminum is an excellent conductor of heat and electricity. This characteristic allows aluminum coils to effectively distribute and dissipate heat, preventing the transfer of thermal energy from one side of the product to another. By doing so, aluminum coils act as a barrier, minimizing heat loss or gain, which is essential for maintaining optimal temperatures in different applications. Secondly, aluminum coils have a low thermal conductivity. This means that they are not easily affected by temperature changes and do not readily transfer heat. As a result, products containing aluminum coils can better resist external temperature fluctuations, providing better insulation against hot or cold conditions. Furthermore, aluminum coils are lightweight, making them easy to handle and install in various products. This lightweight property is advantageous as it does not add significant weight to the overall structure, making it suitable for industries that require portable or lightweight insulation solutions. Moreover, aluminum is highly resistant to corrosion, making it ideal for applications in humid or corrosive environments. This durability ensures that the insulation properties of products containing aluminum coils remain effective over an extended period, without deteriorating or compromising performance. Additionally, aluminum is a recyclable material, which aligns with sustainable practices. Using aluminum coils in insulation products promotes environmental consciousness by reducing waste and energy consumption associated with manufacturing new materials. In summary, aluminum coils contribute to the insulation properties of products by efficiently distributing and dissipating heat, minimizing heat transfer, and resisting temperature fluctuations. Their lightweight nature, durability, and recyclability further enhance their effectiveness as an insulation component. Overall, aluminum coils are a valuable addition to insulation systems, improving thermal efficiency and reducing energy consumption.

- Q: How are aluminum coils tested for quality control?

- Aluminum coils undergo several tests during quality control to ensure their reliability and performance. One of the primary tests is the dimensional inspection, where the physical dimensions of the coils are measured and compared against the specifications provided by the manufacturer. This helps to identify any discrepancies in length, width, thickness, or diameter. Another crucial test is the visual inspection, where the coils are thoroughly examined for any surface defects such as scratches, dents, or discoloration. This visual examination is essential to ensure that the coils meet the required aesthetic standards. To evaluate the mechanical properties, various mechanical tests are conducted. Tensile strength tests are performed to measure the resistance of the aluminum coils to breaking under tension. This test helps in determining the durability and strength of the coils. Additionally, hardness tests are carried out to assess the coil's resistance to indentation or deformation. The hardness values are compared against the predetermined standards to verify if the coils meet the necessary criteria. Further tests include corrosion resistance testing, where the coils are exposed to harsh environments or corrosive substances to assess their ability to withstand corrosion over time. This test is crucial as aluminum is often used in applications where it may come into contact with corrosive elements. Electrical conductivity tests are conducted to ensure the proper functioning of the coils in electrical applications. The conductivity is measured and compared with the required specifications to guarantee that the coils possess the desired electrical characteristics. In addition to these tests, other factors like chemical composition analysis, surface roughness evaluation, and coating adhesion tests may also be performed depending on the specific requirements of the aluminum coils. Overall, through these comprehensive quality control tests, manufacturers can ensure that aluminum coils meet the necessary standards, guaranteeing their quality, performance, and reliability in various applications.

- Q: What benefits can be gained from utilizing aluminum coil insulation in various applications?

- <p>Aluminum coil insulation offers several advantages, including high thermal conductivity, which allows for efficient heat transfer. It is lightweight and corrosion-resistant, making it durable and suitable for various environments. The material is also known for its flexibility, which facilitates easy installation and adaptability to different shapes and sizes. Additionally, aluminum coil insulation has good electrical conductivity, which can be beneficial in applications requiring electromagnetic shielding. Its recyclability contributes to environmental sustainability, reducing waste and promoting green practices.</p>

- Q: Can a spring balance be used to accurately determine the weight of an aluminum coil?

- <p>Yes, you can use a spring balance to measure the weight of an aluminum coil, but the accuracy depends on the balance's specifications. Ensure the balance has a sufficient capacity to measure the coil's weight and is calibrated correctly. Keep in mind that spring balances are less precise than electronic scales, especially for heavy or sensitive measurements. For high accuracy, consider using an electronic scale designed for industrial use.</p>

- Q: Are aluminum coils suitable for roofing?

- Yes, aluminum coils are suitable for roofing. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an excellent choice for roofing applications. It is also highly reflective, which can help to reduce energy costs by keeping the building cooler. Additionally, aluminum coils are easy to install and maintain, making them a popular option for both residential and commercial roofing projects.

- Q: This question asks for criteria or methods to determine if a used aluminum coil is safe for reuse.

- <p>To determine if a used aluminum coil is safe to use, consider the following: Check for any visible signs of damage such as cracks, dents, or corrosion. Ensure the coil has been properly cleaned and sanitized to remove any residues or contaminants. Verify that the coil has not exceeded its recommended lifespan or usage limits. Consult the manufacturer's guidelines for any specific safety checks or maintenance requirements. If in doubt, it's best to consult with a professional or replace the coil to avoid potential safety hazards.</p>

Send your message to us

Hot Rolled Aluminum Coil for Metal Roofing System - Color Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords