Prepainted Galvanized/Aluzing Steel coils for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details

Basic Info.

Model NO.:G550, FULL HARD, SGHC

Type:Steel Coil

Standard:ASTM, GB, JIS

Certification:ISO, SGS, BV

Surface Treatment:Coated

Technique:Hot Rolled

Special Use:High-strength Steel Plate

Base Metal:Galvanized or Galvalume Steel

Width:914/1000/1200/1219/1220/1250mm

Thickness:0.16-1.2mm

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

Top Side Painting:15-25 Micron

Back Side Painting:5-8 Micron

Colour:Ral Standard or According to Customers′ Requirment

Coil Weight:3-6 Mt

Coil ID:508/610 Mm

Export Markets:North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Packing:Seaworthy Packing

Standard:0.135-1.2MM

Origin:China, Shandong

HS Code:72107000

Production Capacity:180000mt

Product Description:

1. Standard: AISI, ASTM, BS, DIN, GB, JIS, ASTM, JIS, GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC, SPCD, DC01, ST12, ST13, Q195, 08AL

3. Thickness: 0.13-0.5mm

4. Width: 600-1250mm

5. Length: Up to The Thickness or as require

6. Spangle: Zero, Mini, Regular, Big, Skin Pass

7. Audited Certificates: BV, SGS, ISO, CIQ

8. Zinc Coating: 40g-200g

9. Surface: Chromated, dry/oiled, Cr3 treated anti-finger

10. Package: Standard exporting package (or as required)

11. ID: 508/610mm

Specification:

| commodity | Color Coated Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Base metal | galvanized, galvalume, cold rolled steel |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness) |

| Width | 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

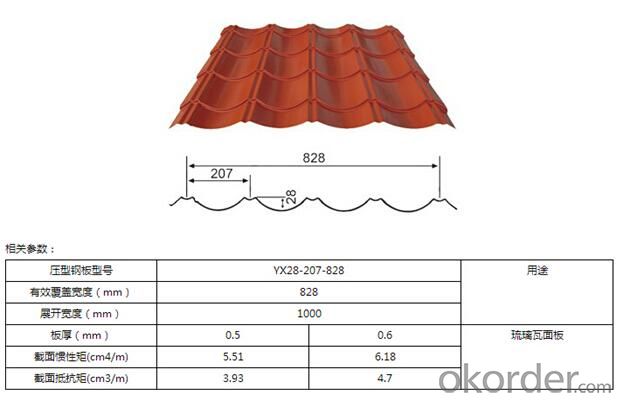

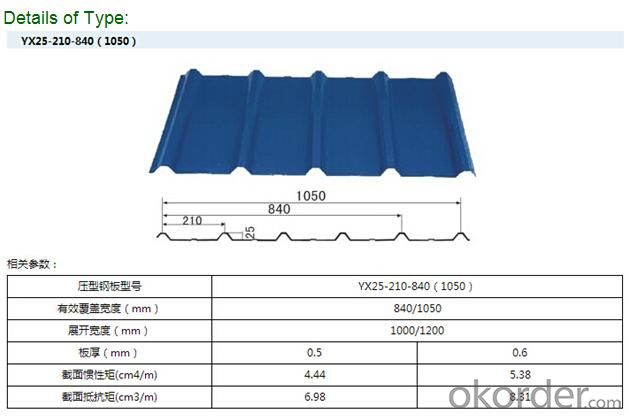

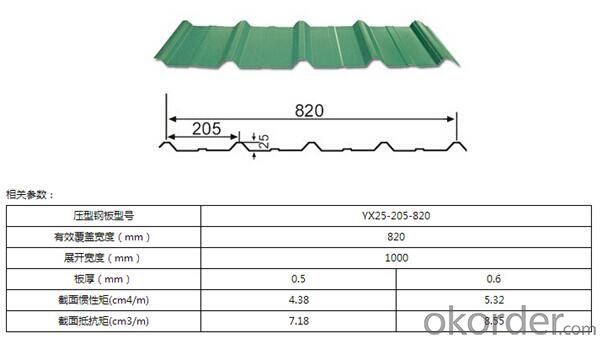

Details of Type:

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: Whats the difference in composition? When LTCS is used generally?Whats the temperature range, that these materials can be used? Is there any relation between Killed carbon steel, LTCS, stainless steel, carbon steel(normal)? How to categorise/classify these?Thankyou very much in advance..

- Low Temperature Carbon Steel

- Q: How are steel coils used in the production of steel fasteners?

- Steel coils are used in the production of steel fasteners by being processed into flat strips or wires, which are then cut, shaped, and threaded to create various types of fasteners such as screws, bolts, and nuts. The coils provide a continuous supply of steel material that is easily manipulable and can be efficiently transformed into the desired shape and size for fastener production.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: Molten steel changes to solid steel at its __________ point. Could you please fill in the blank? Thank you so much, it is greatly appreciated. I have been looking for the answer to this question for a long time, but I never understand what the websites are trying to say because I don't have that big of a vocabulary and don't know what they mean. I've seen things saying steel boiling point, steel melting point, and steel freezing point. I don't know what any of those mean, and they might be the answer. Please help me. Thank you.

- just like a melting point of ice and the boiling point of water, there are different points where something is converted into another form. such as icewatersteam. it's always the same thing and it's a physical change, but just in a different form. molten steel changes to solid steel at it's freezing point. or solid point. i'm not sure how you would word that. but it would not be melting or boiling point. hope that helped.

- Q: How are steel coils used in the manufacturing of engine components?

- Steel coils are used in the manufacturing of engine components as they provide a strong and durable material for various parts. These coils are typically processed and shaped into specific components such as pistons, crankshafts, cylinder heads, and connecting rods, which are vital for the proper functioning of an engine. The high strength and heat resistance of steel make it an ideal choice for these critical components, ensuring the engine's reliability and performance.

- Q: Looking for an insight here into what hiking with steel toe-capped boots would be like, as I saw a nice pair of steel toed magnums that I plan to use for my future hiking (which I will be doing a fair amount of in the future). They seemed fairly comfortable, but I am curious into what others have to say and what might be known of this sort of approach. Thanks in advance.

- They are very heavy not like hiking boots but it is your choice

- Q: How are steel coils used in the production of metal ductwork?

- The production of metal ductwork relies heavily on steel coils. Typically constructed from high-quality steel, these coils serve as the primary raw material for manufacturing ductwork. To begin the process, the steel coil is unwound and then cut into specific lengths based on the required dimensions of the ductwork. These lengths are then shaped using specialized machinery, such as roll formers or bending machines, to achieve the desired form. The steel coils are essential in providing the necessary strength and durability to the ductwork, ensuring its ability to withstand the pressure and environmental conditions it may encounter during operation. Additionally, the composition of the coil allows for easy fabrication and customization, enabling manufacturers to produce ductwork in various shapes and sizes to meet specific project requirements. Moreover, steel possesses inherent properties that make it an ideal material for ductwork. Its resistance to corrosion and fire makes it highly desirable. Steel coils can also be coated with protective layers, such as galvanized or stainless steel finishes, to further enhance their longevity and performance. This added protection ensures that the ductwork remains intact and functional, even in harsh environments or when exposed to corrosive substances. In conclusion, steel coils are indispensable in the production of metal ductwork as they provide the necessary raw material for fabrication. Their strength, durability, and customization capabilities make them a crucial component in the manufacturing process, resulting in reliable and long-lasting ductwork systems.

- Q: What are the different testing methods used for steel coils?

- There are several testing methods used for steel coils, including visual inspection, dimensional measurement, hardness testing, tensile testing, chemical analysis, and non-destructive testing techniques such as ultrasonic testing and magnetic particle inspection. These methods help ensure the quality and integrity of steel coils, allowing for accurate assessment of their mechanical properties, composition, and structural soundness.

- Q: earlier name of jsw steel ltd. may be jindal iron steel ltd.

- JSW Steel Ltd - Profile Office Address 5 A, Jindal Mansion, Dr A G Deshmukh Marg, Mumbai Maharastra 400026 Phone 022-23513000 Business Summary JSW Steel Limited Formerly known as Jindal Vijayanagar Steel Limited. The Company's principal activity is to manufacture hot rolled steel coils in India using the revolutionary Corex technology. In addition, the Company also manufactures steel plates and sheets. It manufactures steel using oxygen based iron and steel through continuous casting and hot rolling. Executive Team Executive Name Designation Savitri Devi Jindal Sajjan Jindal Dr. B N Singh Chairperson Additional Director Vice Chairman Managing Director Joint Managing Director

- Q: What are the common uses of galvanized steel coils?

- Galvanized steel coils are commonly used in various industries for their corrosion resistance and durability. They are extensively used in construction for roofing, walls, and structural components. Galvanized steel coils are also used in the automotive industry for manufacturing parts like car bodies, frames, and exhaust systems. Additionally, they find applications in the manufacturing of appliances, electrical enclosures, and agricultural equipment.

Send your message to us

Prepainted Galvanized/Aluzing Steel coils for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords