Roofing Ceiling Decorative Aluminium Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Roofing Ceiling Decorative Aluminium Coated Coil

lProduct Information

Alloy | Thickness (mm) | Width (mm) | Temper | DC or CC |

1050,1060, 1070,1100,1235 | 0.2-3.0 | 20-1800 | O, H12, H22, H14, H24, H16, H26, H18 | DC, CC |

3.0-12.0 | 900-1900 | H111, H112 | DC | |

3003,3004,3105,3005 | 0.2-3.0 | 20-1800 | O, H12, H22, H14, H24, H16, H26, H18 | DC, CC |

3.0-12.0 | 900-1900 | H111, H112 | DC | |

5052,5083,5754,5005 | 0.2-3.0 | 20-1800 | O, H12, H22, H14, H24, H16, H26, H18 | DC |

3.0-12.0 | 900-1900 | H111,H112 | DC | |

8011 | 0.0065-0.2 | 20-1500 | O, H22 | DC,CC |

Interior Diameter | 75mm,150mm etc. or as your request | |||

Outer Diameter | 300mm, 505mm etc. or as your request | |||

lPackaging & Delivery Details

Packaging: Standard seaworthy packing

Delivery: About 25 days after received your advance

lCompany Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building

material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

CNBM has been involved in aluminium products for about a decade. With advanced technology and equipment, our products have been sold to the worldwide including America, Europe, as well as South Asia, etc.

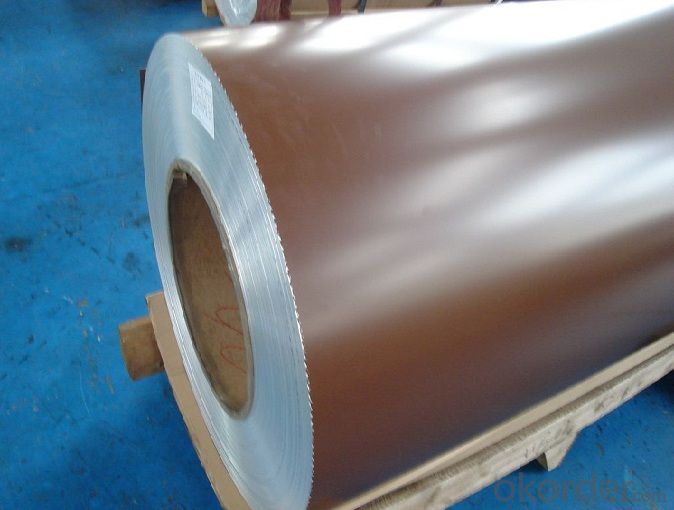

lProduct Images

lCertificates

lFAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

- Q:What are cold rolling aluminum coil and hot rolling aluminum coil? What are their features?

- If the rolling temperature is above the crystallization one, it is hot rolling, otherwise it is cold rolling.

- Q:What are the potential applications of patterned aluminum coils?

- Patterned aluminum coils have a wide range of potential applications in various industries. They can be used for decorative purposes in architecture and interior design, such as wall cladding, ceilings, and facades. Additionally, they are commonly utilized in the automotive industry for decorative trims, grilles, and exterior body parts. The patterned coils can also be used in the manufacturing of household appliances, furniture, and electronics, providing aesthetic enhancements and durability. Furthermore, they have potential applications in packaging, signage, and advertising, as well as in the production of heat exchangers and radiators. Overall, the applications of patterned aluminum coils are diverse and offer a versatile solution for both functional and decorative purposes.

- Q:How are aluminum coils tested for quality control?

- Aluminum coils are tested for quality control through various methods including visual inspection, dimensional checks, surface roughness analysis, mechanical property testing, and chemical composition analysis. These tests ensure that the coils meet the required specifications and standards, guaranteeing their quality and suitability for their intended applications.

- Q:Can aluminum coils be used in the production of aluminum foam panels?

- Yes, aluminum coils can be used in the production of aluminum foam panels. The coils are typically processed through a foaming method, such as powder metallurgy or melt route, to create a foam structure. This allows for the production of lightweight and strong aluminum foam panels suitable for various applications, including in the automotive, aerospace, and construction industries.

- Q:What are the potential challenges in recycling aluminum coils?

- There are several potential challenges in recycling aluminum coils. Firstly, aluminum coils often contain contaminants such as paint, oil, or other coatings that need to be removed before the recycling process can take place. This can be a time-consuming and costly process, as the coils need to be thoroughly cleaned to ensure the quality of the recycled aluminum. Secondly, aluminum coils are often mixed with other materials such as steel or plastic, which further complicates the recycling process. These materials need to be separated from the aluminum before it can be melted down and recycled. This separation process requires specialized equipment and expertise, adding to the overall cost and complexity of recycling aluminum coils. Another challenge is the transportation and logistics involved in recycling aluminum coils. These coils are often large and heavy, making it difficult and expensive to transport them to recycling facilities. Additionally, the recycling facilities themselves need to have the necessary infrastructure to handle and process these coils efficiently. Moreover, the fluctuating market prices of aluminum can also pose a challenge in recycling aluminum coils. The value of recycled aluminum is influenced by factors such as global supply and demand, which can vary significantly over time. This can make it difficult for recyclers to accurately predict the financial returns from recycling aluminum coils, potentially affecting the viability of the recycling process. Lastly, the overall awareness and participation in aluminum coil recycling can be a challenge. Many industries or individuals may not be aware of the benefits of recycling aluminum coils or may not have access to recycling facilities. Increasing education and accessibility to recycling programs can help overcome this challenge and promote the sustainable recycling of aluminum coils.

- Q:What are the common surface finishes for aluminum coils in the aerospace industry?

- Some common surface finishes for aluminum coils in the aerospace industry include anodizing, chromate conversion coating, and primer coating. Anodizing is a process that creates a protective oxide layer on the surface of the aluminum, providing enhanced corrosion resistance and durability. Chromate conversion coating, also known as chemical film coating, forms a thin layer on the aluminum surface that provides corrosion resistance and improves adhesion for subsequent coatings. Primer coating is typically applied on top of anodizing or chromate conversion coating to provide additional protection and enhance the adhesion of subsequent paint layers. These surface finishes are important in the aerospace industry as they help to protect the aluminum coils from corrosion and ensure their longevity in harsh environments.

- Q:When aluminum metal is heated with an element from group VIA of the periodic table, an ionic compound forms. When the experiment is performed with an unknown croup VIA element, the product is 18.56% Al by mass. What is the formula of the compound and what is its name?

- Let's say you have l00 grams of this compound, so inside the compound would be l8.56 grams of Aluminum and the remaining. 81.44 grams of the second element. Elements in group 6A have 6 electrons in their outer shell and an oxidation # of -2 and the formula for the compound would be Al2X3. a 2mole Al to 3 mole X ratio. The compound would have the atom ratio of Al2X3 derived from the valences of +3 and -2. So the two aluminum atoms in the compound would be providing a total mass of l8.56 grams and the three atoms of X would be providing the remaining mass of 81.44 g so we have the ratio. l8.56 g Al/ 2 Al moles = 81.44 grams element X/ 3 moles X The mass ratio between these two elements is 8l.44 over l8.56 or 4.38 to l The atomic wt. total for 2 aluminum atoms is 54 so the atomic wtl total for three atoms of element X should be 4.38 times 54 which is 236.9 Now if we divide 236.9 by three atoms of X in the compound we get an atomic wt. of 78.9 which corresponds to Selenium So the compound is Al2Se3. This was a challenging problem, congratulations to your chem teacher.!!!

- Q:Are aluminum coils suitable for architectural roofing systems?

- Yes, aluminum coils are suitable for architectural roofing systems. Aluminum is lightweight, durable, and corrosion-resistant, making it an excellent choice for roofs. It can withstand harsh weather conditions, is easy to work with, and offers a range of design possibilities. Additionally, aluminum coils are available in a variety of colors and finishes, allowing for customization and enhancing the aesthetic appeal of architectural roofing systems.

- Q:How are aluminum coils annealed?

- Aluminum coils undergo a heat treatment process called annealing, which is typically used to soften the metal and enhance its ductility. This process involves heating the coils to a specific temperature and gradually cooling them. To start the annealing of aluminum coils, thorough cleaning is required to eliminate any impurities. Then, the coils are placed in a furnace that is heated to the desired temperature. The duration and temperature of the annealing process depend on the specific grade and thickness of the aluminum being treated. Once the coils reach the desired temperature, they are maintained at that level for a specific period. This allows the internal structure of the aluminum to become more uniform and relieves any internal stresses that may have occurred during manufacturing. After completion of the annealing process, the coils are slowly cooled within the furnace. This gradual cooling is crucial to prevent the development of new internal stresses. Once the coils reach room temperature, they are ready for further processing or utilization. In some instances, an additional process called quenching may follow annealing. Quenching involves rapidly cooling the aluminum by immersing it in a medium like water or oil. This can further enhance the mechanical properties of the aluminum, such as its strength and hardness. Overall, the annealing process for aluminum coils is a meticulously controlled heat treatment that aims to enhance the metal's properties and make it more suitable for various applications.

- Q:hello, i have been recently studying the production of aluminum from aluminum dross (recycling of aluminum) .this chemical equations represents the hydrolization of sodium aluminate to obtain aluminum hydroxide :Na2Al2O4 + 4H2O -----------gt; 2Al(OH)3 + 2NaOHafter that the next step is to produce Al2O3the next step to obtain Aluminum is to pass a current through the solution (electrolysis)this is the part that i don't get .... how could we electrolyze Aluminium oxide to produce aluminum if we are recycling aluminum ... i mean electrolysis consumes most of the energy and is very expensive .... so how do electrolysis be used in the recycling industry...please answer ... all answers are really appreciated ....and correct me if my informations are wrong...

- Because aluminium is usually used as an alloy, it has to be treated and extracted from the scrap first. This is done by putting it through the same process as extracting the metal from bauxite, which is extraction of pure aluminium oxide and electrolysing it to get the metal. I agree that electrolysis of aluminium oxide costs a lot. However, the efficiency of the recycling is higher, since the aluminium is relatively pure (bauxite is not), and it prevents perfectly usable aluminium being consigned to the scrap heap (preventing landfill at the same time).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roofing Ceiling Decorative Aluminium Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords