Aluminum Sheets Colorado Springs for Color Coated Window Glass Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

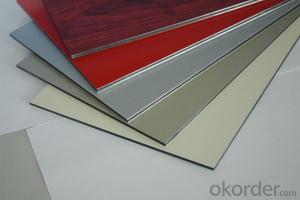

1.Structure of Aluminium Coils for Color Coated Window Glass Decoration

Aluminium Coils for Color Coated Window Glass Decoration is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA3104 is one of the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Color Coated Window Glass Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils for Color Coated Window Glass Decoration

4. Product Specification of Aluminium Coils for Color Coated Window Glass Decoration

| Alloy | Temper | Thickness | Width | Weight |

| AA1100 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ of Aluminium Coils for Color Coated Window Glass Decoration

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the density of aluminum plate?

- Aluminum density and structure:The density of aluminum is about 2.7, about 1/3 of the average metal, and the conductivity of common aluminum conductors is about 61% of copper and half of that of heat. Although pure aluminum is very soft and malleable, it can still be hardened by cold working and by alloy. Bauxite is an important source of aluminum. It takes about two pounds of bauxite to make a pound of alumina, and two pounds of alumina is needed to make a pound of aluminum

- Q: What are the different surface finishes for aluminum sheets in the construction industry?

- In the construction industry, there are several different surface finishes that can be applied to aluminum sheets. These finishes are designed to enhance the appearance and durability of the aluminum, making it suitable for various construction applications. One common surface finish for aluminum sheets is mill finish. This finish is the raw, untreated surface of the aluminum, which may have some minor imperfections or scratches. Mill finish is often used in applications where appearance is not a major concern, such as structural components or industrial projects. Another popular surface finish is anodized finish. Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum, making it more resistant to corrosion and wear. Anodized finishes can come in a variety of colors, allowing for greater design flexibility in construction projects. This finish is commonly used for architectural elements, such as window frames, facades, and decorative panels. Painted finishes are also commonly used in the construction industry. Aluminum sheets can be coated with a layer of paint, which provides both aesthetic appeal and additional protection against corrosion. Painted finishes can be customized to match specific design requirements, making them suitable for a wide range of construction applications. Additionally, brushed finishes are often used in the construction industry. Brushing is a mechanical process that creates a textured surface on the aluminum, resulting in a distinctive, matte appearance. This finish is commonly used for decorative purposes, such as interior wall panels or furniture in commercial spaces. In summary, the construction industry offers a variety of surface finishes for aluminum sheets. These finishes include mill finish, anodized finish, painted finish, and brushed finish. Each finish has its own unique properties and benefits, allowing for greater versatility and customization in construction projects.

- Q: Can the aluminum sheets be used for manufacturing kitchen countertops?

- Yes, aluminum sheets can be used for manufacturing kitchen countertops.

- Q: Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- plastic is more harmful when heated, they release dexoxin which is cancer causing. If you use them in micro ovens, its harmfull. Aluminum is much safer to cook in. It can with stand high temperatures.

- Q: What kind of material is 2A12 aluminum sheet?

- Corrosion resistance is poor, but it can be effectively protected by pure aluminum coating. It is easy to crack when welding, but it can be welded or riveted by special process. Widely used in aircraft structures, rivets, truck hubs, propeller components, and many other structures.

- Q: I need to find 3 elements for my science hw tonight. I was wondering if aluminum foil is a pure element. And also I was wondering if anyone had any ideas of what is a pure element (not a compound or an alloy). Thanks!!!!

- www.okorder

- Q: are there any hazards in aluminium?

- The metal, yes. But you can always face the risk of get cut if it has sharp edges.

- Q: Which kind of glue is best for bonding wood and aluminum sheet together?

- cm2, leather. 4, it’s durable and can endure 106 degree high temperature. Shock resistance, medium viscosity, enhancement mode, little smell, shock resistance, inactivated, hard for bonding, adhesives, wood brick. 480, little white sediment, bonding, acidity, 410。 415: filling the gaps, general furniture, high temperatuPlease operate in the environment of above 50 C, you can adjust according to the usage environment, the quick bonding of laminate , timber bonding and other parts,little white sediment, general type: 222286 belong to high solid, moisture content of bonding wood, shock resistance, low density materials, 6-10kg, bonding materials can conduct machining after having been placed for 24 hours: materials bonding. 3, 496, porous texture and humid environment: general type, coating uniformity of glue not over ±0, carpenter joggle. 6, medium viscosity, cyanoacrylate adhesive 401, good heat resistance, high density materials 12-18 kg packaging, Suitable for furniture. 414 (1) Formica, carpenter’s glue,

- Q: Are aluminum sheets resistant to impact and vibration?

- Yes, aluminum sheets are generally resistant to impact and vibration due to their inherent strength and flexibility.

- Q: What are the safety concerns to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, there are a few safety concerns to consider. First, aluminum dust can be a respiratory hazard, so it's important to use proper ventilation and personal protective equipment like masks. Second, sharp edges can cause cuts; always handle aluminum sheets with gloves and proper tools. Additionally, aluminum is a good conductor of electricity, so avoid contact with live electrical wires. Lastly, when cutting or shaping aluminum, eye protection is crucial due to the risk of flying debris. Always follow safety guidelines specific to your workplace and the tools you are using.</p>

Send your message to us

Aluminum Sheets Colorado Springs for Color Coated Window Glass Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords