Schuco Aluminum Profiles for Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

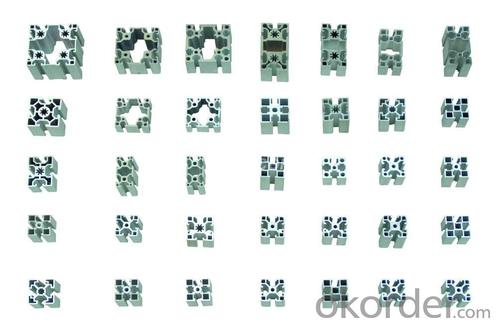

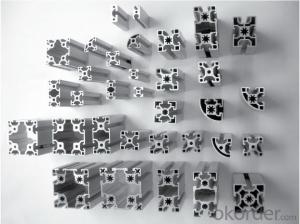

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Knowledge of aluminum profile warehouse management (detail)

- Warehouse management is the main task required under the factories and production equipment condition of overall planning, rational layout; to strengthen the internal economic responsibility system, scientific division, forming material export management guarantee system; business must implement the work quality standardization, application of modern management technology and the ABC classification method, and constantly improve the level of warehouse management. The main work is material inspection, income, inventory, storage and custody of materials, materials delivery, billing statements, etc.

- Q: How do aluminum profiles perform in seismic or earthquake-prone areas?

- Aluminum profiles have shown to perform well in seismic or earthquake-prone areas due to their inherent properties. Aluminum is a lightweight and flexible material, which allows it to absorb and dissipate seismic energy effectively. This helps in reducing the impact of earthquakes on structures and minimizing damage. Additionally, aluminum profiles are highly resistant to corrosion, which is beneficial in areas with high seismic activity as it ensures the longevity and structural integrity of buildings.

- Q: How do you ensure proper weatherproofing with aluminum profiles?

- To ensure proper weatherproofing with aluminum profiles, there are several key measures that can be taken. Firstly, it is important to select high-quality aluminum profiles that are specifically designed for weather resistance. These profiles should be treated with a suitable finish or coating that provides protection against corrosion and weather elements. Next, proper installation techniques should be followed to ensure a tight and secure fit. This includes ensuring that the profiles are correctly aligned and joined together using appropriate fasteners or adhesives. Any gaps or openings between the profiles should be sealed with weatherproofing materials such as silicone or rubber gaskets to prevent water or air infiltration. In addition, it is crucial to pay attention to the design and construction of the aluminum profiles. This involves incorporating features like sloped surfaces, drip edges, and drainage systems to facilitate water runoff and prevent pooling or accumulation. Adequate provisions should also be made to address thermal expansion and contraction, which can affect the weatherproofing performance of the profiles. Regular maintenance is another important aspect in ensuring long-lasting weatherproofing. Periodic inspections should be conducted to identify any signs of wear, damage, or deterioration in the profiles or their weatherproofing elements. Any issues should be promptly addressed through repairs or replacement to maintain the integrity of the weatherproofing system. Overall, by selecting quality aluminum profiles, following proper installation techniques, incorporating suitable design features, and conducting regular maintenance, one can ensure proper weatherproofing with aluminum profiles and enhance their durability and performance against weather elements.

- Q: What is the price of fluorocarbon coated aluminum profiles, please?

- Powder sprayed surface of about 2W a meal, fluorocarbon two or three coated difference about 800 yuan, 2.5W a meal bar, depends on what brand products, this price is now according to the aluminum ingot price estimate

- Q: What are the bending radii for different aluminum profiles?

- The bending radii for different aluminum profiles can vary depending on the specific shape and thickness of the profile. However, in general, aluminum profiles can be bent to a minimum radius that is typically around 1.5 to 2 times the thickness of the material. For example, if you have an aluminum profile with a thickness of 1mm, the minimum bending radius would be around 1.5 to 2mm. Similarly, if the profile has a thickness of 3mm, the minimum bending radius would be around 4.5 to 6mm. It is important to note that these are approximate values and may vary depending on the specific alloy and temper of the aluminum. Additionally, the bending process itself, including the method and equipment used, can also impact the achievable bending radii. To ensure accurate bending, it is recommended to consult the manufacturer or a professional fabricator who can provide specific guidelines and recommendations for bending radii based on the particular aluminum profile you are working with.

- Q: This question asks if aluminum profiles can be used in cold weather conditions and if they maintain their properties in such environments.

- <p>Yes, aluminum profiles are suitable for use in cold climates. Aluminum is a durable material with excellent resistance to corrosion and weathering, which includes maintaining its integrity in low temperatures. It does not rust or degrade significantly in cold conditions, making it a reliable choice for construction and other applications in cold climates. However, it's important to consider the specific alloy and any protective coatings or treatments that may be necessary to ensure optimal performance in extreme cold.</p>

- Q: How is the tonnage of aluminum profile extrusion machine calculated? Do you have any formulas? For example, 30*60 industrial profiles, the need for a large tonnage of extrusion machine can be done?

- This section is almost the same as a 1500-2000 ton extruder.In general, the extrusion ratio of 6063 profiles will be controlled at around 30-150,That is, the section of rice weight / casting rod of rice weight, or section section area / aluminum bar cross-sectional area.

- Q: How do you attach accessories or components to aluminum profiles?

- There are several ways to attach accessories or components to aluminum profiles. One common method is to use T-slot nuts and bolts. T-slot nuts slide into the T-slot groove on the profile and can be positioned anywhere along the length. The bolts then secure the accessory or component to the nut, creating a strong and secure connection. Another option is to use brackets or mounting plates specifically designed for aluminum profiles. These brackets usually have pre-drilled holes that align with the T-slot grooves, allowing for easy attachment of accessories. They can be fastened to the profile using screws or bolts. Additionally, there are various specialized connectors available for specific applications. Examples include corner connectors, joining plates, and hinge connectors. These connectors provide easy and reliable ways to attach accessories or components to aluminum profiles without the need for additional drilling or machining. It is important to consider the weight and load-bearing requirements of the accessories or components when choosing the attachment method. Using appropriate fasteners and connectors ensures a secure attachment and prevents any potential hazards.

- Q: What is the limitation of aluminum bending

- General extrusion of aluminum quality is soft, over a period of time will be hardened, the longer the material more hard, no impact on the stretch bending, with hydraulic bending machine, there will be no cracks. Dongguan Sheng Hui Machinery Co., Ltd. to serve you. Thanks for taking it

- Q: Are aluminum profiles suitable for use in industrial settings like shelving and storage systems?

- <p>Yes, aluminum profiles are indeed suitable for industrial applications such as shelving and storage systems. They offer several advantages including high strength-to-weight ratio, corrosion resistance, and ease of assembly. Aluminum profiles are lightweight, which makes them ideal for constructing sturdy yet lightweight shelving and storage solutions. Their resistance to corrosion means they can withstand harsh industrial environments without rusting. Additionally, the modular nature of aluminum profiles allows for customizable designs that can be easily adjusted or reconfigured to meet changing storage needs.</p>

Send your message to us

Schuco Aluminum Profiles for Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords