Al-Zinc coated steel Coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

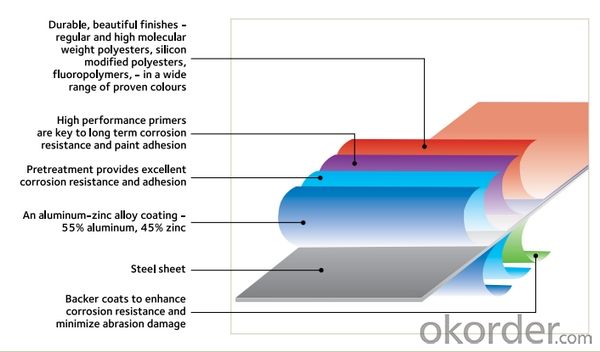

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: i am working in a firm that deals with steels.. so it is necessary for me to understand the chemistry of the steels from their names so that i need not memorize all the grades with their metallury.. where can i find information about this nomenclature ? please help

- For steels with a four number code like 1020, 4140 ect the first two digits are the alloying information. I think you need to memorise those. 10 steels are plain carbon steel with no alloying. 41 steels are chrome-molly. The third and forth digits are the carbon content. 1020 is 0.2% Carbon, 4140 is 0.4% carbon. I don't know if there is a system to stainless steels.

- Q: This problem has puzzled me for a long time i always think about why stranded people on islands cant make a proper civilization and i always think it comes down to the ability to work metal. But its not like they could make a steel smelter/furnace out of sand...they would need an older one to use to make the new one...where the hell did the first one come from then????

- originally steel was made by hand- by hammering an iron ingot (easily obtained from turf iron), heating it in coal (allows the carbon to penetrate the iron) then folding it and hammering it again- several hundred times. with each such procedure the iron absorbs more carbon and becomes steel of course steel smelters made this process simpler- but then you can't get damascene steel out of a smelter... the island civilisations could make smelters out of clay. But finding clay or iron ore on a coral island would be a forlorn task

- Q: What are the common handling defects in steel coils?

- During the transportation and storage of steel coils, various handling defects can arise, impacting the coils' quality and integrity and potentially leading to future problems. Some of the most frequently encountered handling defects in steel coils are as follows: 1. Damage to the edges: This defect occurs when the coil's edges are bumped or scraped, resulting in dents, scratches, or tears. Such damage weakens the coil's structural integrity, making it more susceptible to further harm. 2. Core damage: The core of a steel coil plays a crucial role in maintaining its shape and stability. However, mishandling can crush or deform the core, leading to coil collapse or distortion. 3. Coil slippage: Inadequate strapping or stacking of coils can cause them to shift or slide during transportation. This can result in coil slippage, causing misalignment, damage to the outer layers, or even complete coil failure. 4. Abrasion: Steel coils can experience abrasion if they come into contact with rough surfaces or other objects during handling. This can lead to the wearing off of the coil's protective coating or paint, exposing the steel to potential corrosion. 5. Moisture damage: Steel coils are susceptible to moisture damage, particularly if they are not properly sealed or protected. Exposure to moisture can lead to rust formation, compromising the coil's structural integrity and overall quality. 6. Overloading: Exceeding weight limits and improper stacking of steel coils in trucks or storage areas can exert excessive pressure and stress on the coils, resulting in deformation, bending, or even coil collapse. Adhering to weight limits and proper stacking procedures is crucial to prevent overloading. 7. Improper lifting: When lifting steel coils, it is important to use suitable lifting equipment and techniques. Failure to do so can cause coil damage, such as distortion or bending, and can also pose risks of injury to workers. To mitigate these handling defects, it is vital to adhere to proper handling and storage procedures for steel coils. This includes using appropriate lifting equipment, securing coils during transportation, avoiding overloading, and ensuring adequate protection against moisture and abrasion. Regular inspections and maintenance are also important for identifying and addressing any potential defects or issues before they worsen.

- Q: Can i use steel shot in a remington 870 wingmaster full choke 30 inch barrel. the shotgun is in great shape and about 20 or 25 years old probably. thank you. the steel shot i have got is 12 gauge 2 3/4 in 1550 velocity 1 1/16 oz 2 shot winchester xpert high velocity steel shot

- The biggest problem is the FULL choke on the end of the barrel. Steel pellets are harder than lead, so they find it hard to squeeze through the tight full choke. If you do it, you WILL either bulge or crack the muzzle end of the barrel. That is a fact. Newer model 870 shotguns with RemChokes can fire steel, but you have to use a lead MODIFIED choke to send a full pattern down range. Again, for the same reason I mentioned earlier - that the steel does not deform and squeeze itself through the tighter chokes as well. See photo link below at what your barrel will look like after a box of steel shot.

- Q: What are the common coil coating methods?

- The common coil coating methods include roll coating, spray coating, and coil coating with pre-painted metal substrates.

- Q: How are steel coils tested for strength and durability?

- Steel coils are tested for strength and durability through a series of rigorous tests. These tests typically include tension tests, bend tests, and hardness tests. Additionally, the coils may undergo impact tests to evaluate their resistance to sudden forces. These tests help ensure that the steel coils meet the required standards and can withstand various conditions and applications.

- Q: What are the different certifications required for steel coil manufacturers?

- Some of the different certifications required for steel coil manufacturers include ISO 9001, ISO 14001, OHSAS 18001, and various industry-specific certifications such as the American Society for Testing and Materials (ASTM) certifications. These certifications ensure that the steel coil manufacturers meet quality, environmental, and occupational health and safety standards.

- Q: What is the process for uncoiling and recoiling steel coils?

- The process for uncoiling and recoiling steel coils involves several steps to ensure the safe and efficient handling of the coils. 1. Unloading: The steel coils are typically transported to the desired location using cranes or forklifts. They are carefully unloaded from the transportation vehicle and placed in a designated area. 2. Inspection: Before uncoiling, it is crucial to inspect the steel coils for any damage or defects. This step ensures that only quality coils are processed further. 3. Securing: Once inspected, the steel coils are secured to prevent any movement during the uncoiling process. This is done by using clamps or straps to hold the coils firmly in place. 4. Uncoiling: Uncoiling involves the gradual unwinding of the steel coil. This can be done manually or using specialized machinery such as uncoilers or decoilers. The coil is typically fed through a series of rollers that help guide the unwinding process. 5. Straightening: In some cases, the steel coil may need to be straightened before further processing. This can be done using straightening machines that apply pressure to remove any bends or twists in the steel. 6. Cutting: If required, the uncoiled steel coil may be cut into smaller sections or sheets. This can be done using shearing machines or other cutting tools. The dimensions and size of the cuts depend on the specific requirements of the project. 7. Recoiling: Once the desired processing steps are completed, the steel coil can be recoiled. This involves rewinding the steel into a new coil shape. Recoiling can be done manually or using recoilers, which wind the steel evenly and tightly to maintain its integrity. 8. Packaging and storage: After recoiling, the steel coils are typically packaged and stored for further transportation or use. They may be wrapped in protective materials such as plastic or metal sheets to prevent corrosion or damage. Overall, the process for uncoiling and recoiling steel coils requires careful handling, inspection, and the use of specialized machinery. By following these steps, steel coils can be efficiently processed and prepared for various applications in industries such as construction, automotive, and manufacturing.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being formed into cylindrical shapes and then machined to create the desired dimensions and features of the shaft. The steel coil is typically cut to the required length and then undergoes a series of manufacturing processes, such as forging, heat treatment, and machining, to produce a strong and durable transmission shaft.

- Q: iam talking abt carbon steel of composition:-C=0.15wt% Mn=0.60wt% P=0.035wt% S=0.04wt% Cu=0.20 (min)wt%....

- The composition you mention is not a low carbon steel.The carbon and manganese content are high enough to mean that the crystal grain size will be small. A very large grain size is needed in steels for transformers,motors etc.The large grain size and lack of carbides in low silicon steels for magnetic purposes allows the easy movement of magnetic domain walls.Transformer steels typically have a carbon content of about 0.003% and 3.5%Si with the phosphorus and sulphur at a tenth of the levels you mention.The high Si content increases the electrical resistivity of the magnetic core and reduces the power loss from eddy currents(the core metal has voltages generated in it by the changing magnetic fields) and the power lost in eddy currents heats up a transformers core so it needs extra cooling;the loss is inversely proportional to the resistivity and 3.5%Si increases resistivity of iron by a very large amount.The presence of high silicon with ultra low carbon and manganese level allows the soft magnetic steels to be annealed at very high temperatures(850 to 1100deg C)without a phase change so that the crystals have 10,000 to 10,000,000 times the volume of the crystals in heat-treatable (Just)steel you mention.Fine for playing with and demonstrating electromagnetism but not as electrical engineering feedstuff.

Send your message to us

Al-Zinc coated steel Coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords