All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

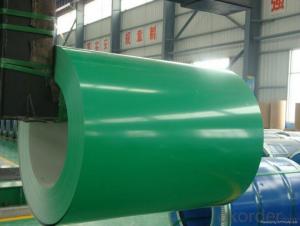

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are stainless steel coils used in the food and beverage industry?

Stainless steel coils are widely used in the food and beverage industry due to their exceptional properties. These coils are primarily used for heating or cooling applications in processing equipment such as ovens, boilers, refrigerators, and pasteurizers. The corrosion-resistant nature of stainless steel ensures that these coils do not contaminate the food or beverage products being processed, maintaining their quality and safety. Additionally, stainless steel coils can withstand high temperatures and pressure, making them ideal for various cooking, chilling, or storage processes in this industry.

How is stainless steel coil used in the production of chemical storage tanks?

Stainless steel coil is commonly used in the production of chemical storage tanks due to its corrosion-resistant properties. The coil is typically formed into sheets, which are then cut and welded to create the tank's structure. The stainless steel material ensures that the tank can withstand the harsh chemicals stored within, preventing leaks, contamination, and damage. Additionally, the coil's durability and strength provide long-lasting performance and stability to the chemical storage tank.

What are the different types of surface textures for stainless steel coil (embossed, etched, etc.)?

Some of the different types of surface textures for stainless steel coil include embossed, etched, brushed, polished, and satin.

What are the different types of surface etching for stainless steel coils?

There are several different types of surface etching methods used for stainless steel coils. These include chemical etching, electrochemical etching, and laser etching. Chemical etching involves applying a corrosive substance to the surface of the steel to remove a thin layer and create a pattern or design. Electrochemical etching uses an electric current and an electrolyte solution to dissolve the surface layer of the steel and create a desired pattern. Laser etching, on the other hand, uses a laser beam to selectively remove material from the surface and create a permanent marking. Each method offers unique benefits and can be chosen based on the specific requirements and desired outcome of the etching process.

How are stainless steel coils used in the electronics industry?

Stainless steel coils are widely used in the electronics industry due to their exceptional electrical conductivity, high resistance to corrosion, and durability. They are commonly employed in various applications such as transformers, capacitors, inductors, and heating elements. These coils help in the efficient transfer of electrical energy, provide stability to electronic circuits, and ensure long-lasting performance of electronic devices.

Wholesale Stainless Steel Coil from supplier in Ghana

Our team is highly knowledgeable about the specifications, applications, and industry standards for Stainless Steel Coil products. We can assist you in selecting the right products for your specific requirements and provide competitive pricing. Furthermore, our technical support services ensure that you receive the necessary guidance and assistance throughout your project.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to source high-quality Stainless Steel Coil products at competitive prices. Our efficient supply chain management ensures timely delivery of your orders, minimizing any potential delays or disruptions.

We understand the unique challenges and requirements of the Ghanaian market and can provide valuable insights and recommendations to help you make informed decisions. Whether you need Stainless Steel Coil products for construction, manufacturing, or any other application, we have the expertise to meet your needs.

Contact us today to discuss your Stainless Steel Coil requirements in Ghana. Our dedicated team is ready to provide you with exceptional service and support.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to source high-quality Stainless Steel Coil products at competitive prices. Our efficient supply chain management ensures timely delivery of your orders, minimizing any potential delays or disruptions.

We understand the unique challenges and requirements of the Ghanaian market and can provide valuable insights and recommendations to help you make informed decisions. Whether you need Stainless Steel Coil products for construction, manufacturing, or any other application, we have the expertise to meet your needs.

Contact us today to discuss your Stainless Steel Coil requirements in Ghana. Our dedicated team is ready to provide you with exceptional service and support.