All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

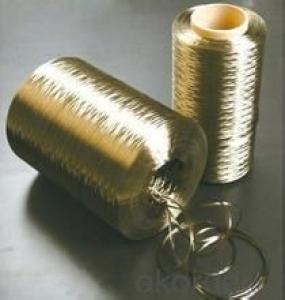

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is fiberglass roving processed into finished products?

Fiberglass roving is processed into finished products through a series of steps including cutting, combining with resin, molding, curing, and finishing. Initially, the roving is cut into desired lengths and then combined with resin to form a reinforced composite material. This mixture is then molded into the desired shape using various techniques such as hand lay-up, spray-up, or filament winding. After molding, the product undergoes a curing process to solidify the resin and strengthen the composite. Finally, the finished product is trimmed, polished, and inspected for quality before being ready for use in various industries such as automotive, construction, and aerospace.

What is the abrasion resistance of fiberglass roving?

The abrasion resistance of fiberglass roving is high.

How does the abrasion resistance of fiberglass roving compare to other materials?

The abrasion resistance of fiberglass roving is generally considered to be superior to many other materials. Due to its high tensile strength and durability, fiberglass roving can withstand heavy wear and tear, making it ideal for applications that require resistance to abrasion, such as in the construction industry or for manufacturing protective equipment.

How is fiberglass roving used in the construction industry?

Fiberglass roving is commonly used in the construction industry as a reinforcement material. It is incorporated into various construction products such as insulation, roofing, and composite materials. The roving, consisting of multiple strands of fiberglass, provides strength, durability, and flexibility to these construction materials, making them resistant to stress, impact, and weather conditions. It is often used to reinforce concrete structures, pipes, and panels, enhancing their overall strength and longevity. Additionally, fiberglass roving can be woven into fabrics and used for applications like reinforcement in wall coverings and floorings.

Wholesale Fiberglass Roving from supplier in Ghana

Thank you for considering our company as your Fiberglass Roving supplier in Ghana. We are confident that our extensive range of products, tailored services, and deep understanding of the local market will meet and exceed your expectations.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide you with the highest quality Fiberglass Roving products. Our commitment to customer satisfaction means that we will go above and beyond to ensure that you have a seamless and efficient procurement experience.

Whether you are in the construction, manufacturing, or any other industry, our Fiberglass Roving solutions are designed to meet your specific needs. With our one-stop procurement services, you can conveniently access a wide variety of products without the hassle of importing from overseas.

Our extensive experience in the Ghanaian market allows us to offer not only top-quality products but also valuable industry knowledge and guidance. We understand the unique challenges and opportunities that businesses face in Ghana, and we are here to support you every step of the way.

When you choose us as your Fiberglass Roving supplier, you can trust that you are partnering with a reliable and knowledgeable team. We are committed to delivering excellence in every aspect of our services, from product quality to competitive pricing and exceptional customer support.

Experience the difference of working with a trusted Fiberglass Roving supplier in Ghana. Contact us today and let us assist you in achieving your project goals with our top-notch products and services. We look forward to serving you.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide you with the highest quality Fiberglass Roving products. Our commitment to customer satisfaction means that we will go above and beyond to ensure that you have a seamless and efficient procurement experience.

Whether you are in the construction, manufacturing, or any other industry, our Fiberglass Roving solutions are designed to meet your specific needs. With our one-stop procurement services, you can conveniently access a wide variety of products without the hassle of importing from overseas.

Our extensive experience in the Ghanaian market allows us to offer not only top-quality products but also valuable industry knowledge and guidance. We understand the unique challenges and opportunities that businesses face in Ghana, and we are here to support you every step of the way.

When you choose us as your Fiberglass Roving supplier, you can trust that you are partnering with a reliable and knowledgeable team. We are committed to delivering excellence in every aspect of our services, from product quality to competitive pricing and exceptional customer support.

Experience the difference of working with a trusted Fiberglass Roving supplier in Ghana. Contact us today and let us assist you in achieving your project goals with our top-notch products and services. We look forward to serving you.