Al-Zinc Coated steel Coil for construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

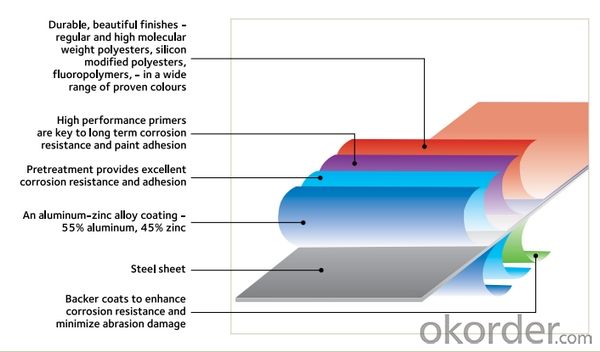

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coil surface appearances?

- The different types of steel coil surface appearances include hot rolled, cold rolled, galvanized, coated, and textured finishes.

- Q: What is the role of steel coils in the manufacturing of appliances?

- Steel coils play a crucial role in the manufacturing of appliances as they serve as the primary material for constructing the appliance's body and various components. The coils are processed, shaped, and transformed into different parts, such as the outer casing, inner structures, and internal components, providing strength, durability, and stability to the appliances. Additionally, the steel coils can be easily customized to meet specific design requirements, ensuring the appliances are efficient, reliable, and capable of withstanding the demands of daily use.

- Q: At what temperature does steel start to warp or soften.

- Steel will only warp due to temperature under two conditions: 1. It is not heated evenly - in this case, the hotter parts will expand more than the cooler parts. 2. There are internal stresses in the steel (often from welding or cold-working - as an example, an I-beam or C-channel is usually hot worked, but some cold work can happen, so they can sometimes warp if you heat them ). This means that the steel won't warp due to temp if it's not 1 or 2. However, it could soften and fail if it has a load on it. As for softening, it really depends on what steel alloy you're looking at. Some steels (mainly the expensive alloys) don't really change until above 400 C (750 F), but mild steel really starts to weaken around 150-200 C (300-400 F) Rajashekhar has a point when it comes to forging. Steel isn't really soft enough to forge properly until above 1000C (1830 F), but if you're worried about using steel in a higher temp situation (like around a blast furnace or industrial oven), then make sure you choose a steel that has been rated to work at that temp.

- Q: I expect that I will be questioned about my knowledge in methoding for steel castings, in a interview. I dont know about it. Can someone explain me in simple language and give me some links, like how I can explain methoding for steel castings.....key points...help please...so that i will pass the interview as if I have experience in methoding....thanks

- It is very difficult to define Methoding of Steel castings by one sentence. Actually it encompasses the total casting process. Normally it would mean a) Pattern design i.e. what type of pattern it would be- wooden, metallic, split or full, loose or fitted on a match plate or any other, how will be the parting line. b) Design of the gating system. c) Design of risering i.e. numbers, size and location of risers. d) Design of molding process i.e. sand system to be used, mold box size. But to do justice to the above mentioned activities, you need to consider other parameters of the casting process such as chemical composition, solidification characteristics, pouring temperature, pouring time, knock out time etc. As I said Methoding of Steel castings means designing of the total casting process from inception to final product.

- Q: How do steel coils impact the overall cost of production?

- The overall cost of production in various industries is greatly affected by steel coils. Initially, the expense of the steel coils themselves can be quite significant. The price of steel is influenced by several factors, including supply and demand, raw material costs, and market fluctuations. Any increase in the price of steel coils can directly impact the overall cost of production, as they are a major component in the manufacturing process. Furthermore, the operational costs of production are also influenced by steel coils. These coils are commonly used in different manufacturing processes, such as stamping, rolling, and forming, which require specialized machinery. The efficiency and effectiveness of these processes greatly depend on the durability, quality, and size of the steel coils. If the coils are of low quality or not suitable for the specific production requirements, it can result in increased downtime, machinery maintenance, and rework, all contributing to higher production costs. Additionally, the transportation costs associated with steel coils can impact the overall cost of production. Steel coils are typically heavy and bulky, requiring special handling and transportation arrangements. The logistics costs can be significantly influenced by factors such as the distance between the supplier and the production facility, as well as the chosen mode of transportation. Any rise in transportation expenses, such as fuel prices or shipping fees, can directly affect the overall cost of production. Lastly, the availability of steel coils can also impact production costs. During periods of high demand or limited supply, the price of steel coils may increase, resulting in higher production costs. Moreover, if there is a shortage of steel coils due to trade restrictions or disruptions in the supply chain, manufacturers may have to resort to alternative materials or sources, which could be more expensive or of lower quality. These factors can have a ripple effect on the overall cost of production. In conclusion, steel coils have a significant impact on the overall cost of production. Their cost, quality, transportation, and availability all influence the efficiency, effectiveness, and affordability of the manufacturing process. Therefore, manufacturers must carefully consider and manage these factors to optimize their production costs and maintain competitiveness in their respective industries.

- Q: i have noticed in guns, and artillery the shell casings are always made out of brass. brass is expensive, weaker and dosnt look as good as steel. so why use it for casings? i am aware some of the case must be deformed. but just a small brass percussion cap could be used just for that and steel for the rest. whats going on?

- Brass has a natural lubricity that makes easier to extract after firing. It also can easily be resized for reloading. Steel offers neither of these properties. It cannot be reloaded so is good for only one single use. Brass has simply shown, by virtue of its metallic characteristics, to be the best choice for manufacturing cartridges.

- Q: Would the Ruger Sr22 pistol or the SW MP 15-22 be any good for the steel challenge?

- Actually Steel Rain, they do have steel plate challenges for 22s. These were added to draw in family and younger people. The SR22 is a compact pistol, and may not have enough muzzle velocity to be effective short of perfect shot placement. If you choose to use it, make sure your ammo is highly reliable in it. Frankly, I'd go with a Ruger MK2 or MK3, bull barrel, 5 over the SR22. The MP 15-22, and the SR-22 rifle will be fine in the rifle group. Again, make sure you have ammo that your rifle likes. And bring more ammo than you think you need. Nothing worse than running out. Have fun!

- Q: How do steel coil manufacturers ensure fair pricing?

- Steel coil manufacturers ensure fair pricing through various measures. Firstly, they conduct thorough market research to understand the current industry trends, demand-supply dynamics, and competitor pricing. This helps them determine a competitive yet fair pricing strategy that aligns with market standards. Secondly, steel coil manufacturers consider the cost of raw materials, production, and operational expenses to determine a reasonable base price. They also factor in economies of scale, as larger production volumes can lead to lower costs per unit. Additionally, steel coil manufacturers often establish long-term partnerships with suppliers to ensure a stable and consistent supply of raw materials at fair prices. This allows them to maintain a reasonable cost structure and minimize price fluctuations. Furthermore, these manufacturers strive for transparency in pricing by providing detailed quotations that break down the cost components. This helps customers understand the factors contributing to the final price and ensures fairness in the pricing process. To enhance fairness, steel coil manufacturers also consider the specific requirements of their customers. They may offer customized pricing based on factors such as order volume, delivery timelines, and value-added services. This approach ensures that each customer receives a price that is commensurate with their unique needs and requirements. Overall, steel coil manufacturers ensure fair pricing by conducting market research, considering cost factors, maintaining transparent pricing practices, and offering customized pricing options. By doing so, they aim to create a fair and mutually beneficial pricing environment for both themselves and their customers.

- Q: Can steel coils be used in the automotive industry?

- Yes, steel coils can be used in the automotive industry. Steel coils are commonly used in the manufacturing of various automotive parts and components, including body panels, chassis, frames, and suspension systems. The high strength and durability of steel make it an ideal material for ensuring the safety and structural integrity of vehicles. Additionally, steel coils can be easily shaped and formed to meet the specific design requirements of different automobile models, making them a versatile choice for the automotive industry.

- Q: Is there much difference? Which is better? Are they equally safe? Is it just personal preference? Can you reccomend a good comfortable steel composite toe boot?

- steel toe boots are just that a piece of steel fitted over the toes, composite toe boots use other materials that are just as hard BUT they do not have the connectivity levels as steel. if you are working in a cold climate steel toes will freeze them toes right off, also electrical environments. my advice get a good pair of composite ones, and you get what you pay for, its worth the investment. more than you could ever imagine. proper foot support. helps legs cramps, back pain etc...

Send your message to us

Al-Zinc Coated steel Coil for construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords