Al-Zinc coated steel coil For construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

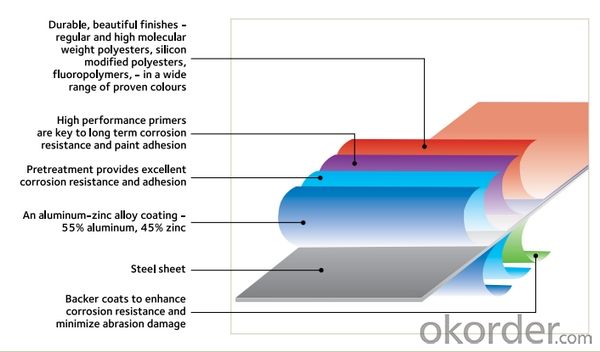

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the maximum temperature that steel coils can withstand?

- The maximum temperature that steel coils can withstand depends on the specific type of steel being used. However, generally, steel coils can withstand temperatures up to around 1,500 degrees Fahrenheit (815 degrees Celsius) before they begin to lose their structural integrity and strength.

- Q: What are the dimensions of steel coils used in the transportation equipment industry?

- The dimensions of steel coils used in the transportation equipment industry can vary depending on the specific application and manufacturer. However, commonly used dimensions range from 0.015 inches to 0.625 inches in thickness and from 24 inches to 60 inches in width. The outer diameter of these coils typically falls within the range of 48 inches to 72 inches.

- Q: Okay, I have looked all ovcer the net and it says diamonds are stronger, but why? I mean, why is diamonds used for the top equiptment rather than steel?

- diamonds are not so much 'stronger' but they are harder than steel. they are harder because of the symmetry of their crystalline structure. Steel can be made harder by helping it's crystalline structure become more symmetrical, but it's not going to have the perfect structure that diamonds do....it's just impossible due to the chemistry of steel. Many industrial drill bits or abrasives use tiny diamonds for the cutting edge, because they are harder and therefore can withstand more abuse before eroding away. coring bedrock is one common application. However, diamonds do have their weaknesses, and by the right person they can be cut along planes with relative ease. diamonds are not malleable or ductile, so making equipment out of them is just not in the cards, not to mention how much money it would cost to do so....and you can't weld diamonds together to make a long piece of diamond, what you get out of the earth is what you get....or they can make diamonds, but still, we can't create diamonds that are multiple feet long!!

- Q: Can you weld copper or brass to steel?

- How To Weld Copper

- Q: What are the different types of steel coil storage locations?

- There are several different types of steel coil storage locations, including warehouse storage, outdoor storage yards, rack storage systems, and automated storage systems.

- Q: How are steel coils used in the manufacturing of industrial valves?

- Steel coils are used in the manufacturing of industrial valves as they provide the necessary raw material for creating valve bodies, stems, and other components. The coils are shaped, cut, and formed into different valve parts, ensuring strength and durability. These steel components are then assembled, welded, and machined to create fully functional industrial valves used in various applications such as oil and gas, chemical processing, and water treatment industries.

- Q: What are the common methods of inspecting steel coils for defects?

- Inspecting steel coils for defects involves several commonly used methods. These methods encompass visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. Visual inspection, the most basic method, entails physically examining the steel coil's surface for noticeable defects like cracks, dents, or irregularities. Typically, this initial step in the inspection process promptly identifies any obvious defects. Ultrasonic testing, a more advanced method, employs high-frequency sound waves to detect defects within the steel coil. Ultrasonic waves are transmitted into the coil via a probe, and any internal flaws or defects reflect the waves back to the probe. This method effectively identifies defects such as voids, cracks, or inclusions. Magnetic particle inspection is another commonly utilized method. It involves magnetizing the coil and applying iron particles to the surface. Defects or cracks disrupt the magnetic field, attracting the iron particles and making them visible. This method is particularly effective for surface cracks or defects. Eddy current testing is a non-destructive method utilizing electromagnetic induction to detect defects in the steel coil. By generating an alternating magnetic field using a probe, any changes in the material's electrical conductivity or magnetic permeability due to defects generate eddy currents. These eddy currents can be measured and analyzed to identify defects like cracks, voids, or changes in material properties. In summary, these common methods offer varying levels of accuracy and sensitivity in inspecting steel coils for defects, ensuring their quality and integrity. The choice of method depends on factors such as the type and size of defects to be detected, the required level of inspection accuracy, and the time and cost limitations of the inspection process.

- Q: I have a set of steel pans with copper bottoms. When I cook with oil it always burns the oil to the pan and takes days to clean. I don't think I should use steel wool, since it might scratch the surface. Does anyone know a faster way to clean scorched oil off a steel pan?

- they have drywall (mudding) sponges to sand mud when you fix walls in the house, they are grey, square, and do not scratch. They seem to work better than any scrubber ever. Make sure you use a degreaser dishsoap like dawn. Maybe try putting your heat lower in the pan and cooking things more slowly?

- Q: How are steel coils used in the agricultural sector?

- Steel coils are widely used in the agricultural sector for various purposes. One of the main uses is in the construction of farm machinery and equipment. Steel coils are often used in the manufacturing of tractors, plows, harvesters, and other heavy-duty machinery. The strength and durability of steel make it an ideal material for these applications, as it can withstand the demanding conditions of agricultural work. Additionally, steel coils are used in the construction of agricultural buildings and structures. Steel is known for its high structural integrity, making it a popular choice for barns, storage units, and other agricultural facilities. Steel coils are often used to create the framework and support systems of these structures, providing stability and long-lasting durability. Moreover, steel coils are used in the production of irrigation systems. The pipes and tubes used for transporting water in agricultural irrigation systems are often made from steel coils. Steel's resistance to corrosion and its ability to handle high-pressure flows make it an excellent choice for this application. In summary, steel coils play a crucial role in the agricultural sector. From the construction of farm machinery and buildings to irrigation systems, steel's strength and durability make it a preferred material in the industry.

Send your message to us

Al-Zinc coated steel coil For construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords