3sp 5sp Q195 Low Carbon Steel Billets Q235 Q275 Q345 Using Good Quailty Ceramic Fiber Bulk

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3sp 5sp Q195 Low Carbon Steel Billets Q235 Q275 Q345 Using Good Quailty Ceramic Fiber Bulk

Description

Reference Price:$260/ton Mn 0.3%-0.6%

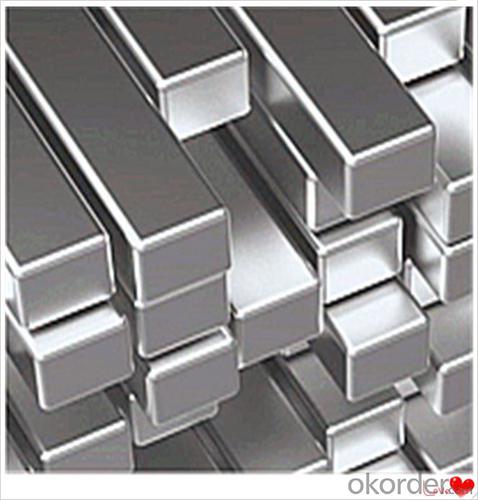

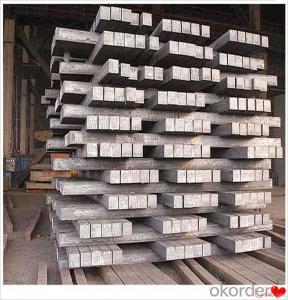

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

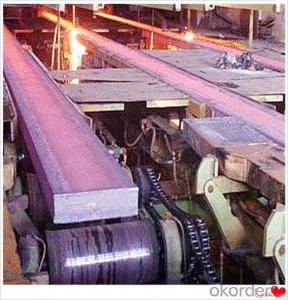

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets labeled for identification purposes?

- Steel billets are typically labeled for identification purposes through various methods such as stamping or tagging, where important information such as size, grade, heat number, and production date are marked directly on the billet or attached to it. This labeling allows for easy traceability and identification throughout the manufacturing and supply chain processes.

- Q: What are the different surface treatments for improved surface lubrication in steel billets?

- To enhance surface lubrication, there are multiple techniques available for treating steel billets. These treatments target the reduction of friction and wear during manufacturing processes like rolling or extrusion. Some commonly used methods to improve surface lubrication in steel billets are: 1. Phosphating: By applying a phosphate coating to the steel surface, this treatment creates a thin layer of phosphate compound. Acting as a lubricant, it minimizes friction between the billet and machinery during processing. 2. Nitriding: Through the introduction of nitrogen into the steel surface, nitriding forms a nitride layer. This layer enhances the billet's surface hardness, wear resistance, and lubrication properties, reducing friction. 3. Electroplating: This treatment involves depositing a layer of metal, such as zinc or nickel, onto the surface of the steel billet. Besides improving lubrication, it also offers corrosion protection, extending the billet's lifespan. 4. Surface coating: Different types of coatings, such as Teflon or polymer-based coatings, can be applied to steel billets. These coatings create a low-friction surface, preventing sticking or galling during processing. 5. Shot peening: Shot peening is a mechanical surface treatment that bombards the steel surface with small, high-velocity metal shots. This process induces compressive stress in the surface layer, enhancing wear resistance and reducing friction. 6. Case hardening: Case hardening involves the diffusion of carbon or other alloying elements into the steel surface through heat treatment. This treatment forms a hardened outer layer, improving lubrication properties and reducing friction during processing. In summary, these surface treatments offer advantages such as reduced wear, improved efficiency, and extended tool life for steel billets. The choice of treatment depends on specific application requirements and the desired properties of the billet.

- Q: Can steel billets be used for structural purposes?

- Yes, steel billets can be used for structural purposes. They are often further processed and shaped into various structural components such as beams, columns, and bars, which provide strength and stability to buildings, bridges, and other infrastructure.

- Q: What is the average price of steel billets?

- The average cost of steel billets may vary due to various factors such as market conditions, supply and demand dynamics, and the grade and quality of the billets. It is crucial to acknowledge that global economic influences, such as raw material expenses, energy prices, and trade policies, can cause fluctuations in the average price. To obtain an accurate understanding of the average steel billet price, it is advisable to consult industry reports, trade publications, and market analysis platforms that offer updated information on steel prices. Additionally, seeking advice from steel suppliers and manufacturers or engaging in negotiations with multiple sources can aid in determining the prevalent average price within a specific region or market.

- Q: What is the role of steel billets in the production of wire rods?

- Steel billets are a crucial raw material in the production of wire rods. They serve as the starting point for the wire rod manufacturing process. The billets are heated and then passed through a series of rolling mills to reduce their thickness and shape them into wire rods. This process helps to improve the mechanical properties and surface quality of the wire rods. Therefore, steel billets play a significant role in ensuring the quality and strength of wire rods used in various industries such as construction, automotive, and manufacturing.

- Q: Can steel billets be polished for improved surface finish?

- No, steel billets cannot be polished for improved surface finish as they are usually unfinished or have a rough surface due to the manufacturing process.

- Q: How are steel billets used in the production of oil and gas exploration equipment?

- Steel billets are commonly used in the production of oil and gas exploration equipment due to their strength and durability. These billets are shaped and machined into various components such as valves, pumps, drilling tools, and pipelines, which are crucial for the extraction and transportation of oil and gas. The high-quality steel ensures that the equipment can withstand harsh operating conditions, including high temperatures, pressure, and corrosive environments, thereby ensuring the safety and reliability of oil and gas exploration operations.

- Q: What is the maximum temperature that a steel billet can withstand?

- The maximum temperature a steel billet can withstand is largely dependent on the specific type and grade of steel being used. However, as a general rule, most steels will lose their structural integrity and mechanical properties when exposed to temperatures above 800 degrees Celsius (1472 degrees Fahrenheit). At these elevated temperatures, steel experiences significant thermal expansion, resulting in distortion, warping, and eventual failure. In specialized applications, certain high-temperature alloys or superalloys have the ability to withstand even higher temperatures. These materials are purposefully designed to maintain their strength and durability under extreme heat, often surpassing 1000 degrees Celsius (1832 degrees Fahrenheit) or more. Nevertheless, it is crucial to understand that determining the maximum temperature a steel billet can endure should always involve consulting the technical data sheet specific to the material or seeking advice from experts in the field. Factors such as alloy composition, heat treatment, and intended usage can all contribute to establishing the maximum temperature limit for a steel billet.

- Q: How are steel billets used in the production of building facades?

- Steel billets are used in the production of building facades as they serve as the raw material for manufacturing different components such as beams, columns, and plates. These billets are hot-rolled or forged into specific shapes and sizes, which are then used to create the structural framework of the facade. Additionally, steel billets are also used to create decorative elements and cladding panels that enhance the aesthetic appeal of the building exterior.

- Q: What are the different sizes and shapes of steel billets?

- Steel billets come in various sizes and shapes, including square, rectangular, and round. The sizes can range from small billets measuring a few inches to larger ones measuring several feet in length and width. The specific size and shape of a steel billet depend on its intended use and manufacturing requirements.

Send your message to us

3sp 5sp Q195 Low Carbon Steel Billets Q235 Q275 Q345 Using Good Quailty Ceramic Fiber Bulk

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords