200 300 Series Grade 2B Stainless Steel Sheet Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

200 300 Series Grade 2B Stainless Steel Sheet Manufacturer

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

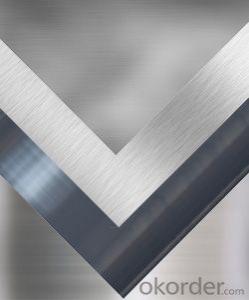

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: What are the pricing options for stainless steel sheets?

- The pricing of stainless steel sheets can vary depending on a range of factors. First and foremost, the grade of stainless steel used plays a significant role. Stainless steel is available in various grades, each offering different levels of corrosion resistance and durability. Higher-grade stainless steel sheets generally come at a higher price. Another factor that influences pricing is the thickness and size of the sheets. Thicker and larger stainless steel sheets tend to be more expensive due to the increased amount of raw material required and the additional processing involved. Moreover, the finish of the stainless steel sheets can also impact the pricing. Different finishes, such as brushed, mirror, or matte, are available for stainless steel sheets. Finishes that necessitate more extensive processing and polishing may come at a higher cost. Additionally, market conditions, including the supply and demand for stainless steel, can affect pricing. Prices can fluctuate based on factors such as raw material costs, production capacity, and global economic conditions. Furthermore, it is crucial to consider the supplier or manufacturer from whom you are purchasing the stainless steel sheets. Different suppliers may offer varying pricing options based on their overhead costs, production capabilities, and market positioning. To summarize, the pricing options for stainless steel sheets are influenced by factors such as grade, thickness, size, finish, market conditions, and the supplier. It is advisable to conduct thorough research and compare prices from different sources to find the most suitable option for your specific requirements.

- Q: How do you prevent distortion when welding stainless steel sheets?

- In order to prevent distortion while welding stainless steel sheets, it is important to follow several key steps and precautions: 1. Begin by ensuring that the stainless steel sheets are thoroughly cleaned and free from any contaminants, such as oil, grease, or dirt. Use an appropriate solvent or degreaser to clean the surfaces before welding. This will help to avoid trapping impurities in the weld, which can cause distortion. 2. Accurate fit-up of the stainless steel sheets is crucial to minimize distortion. Make sure that the edges of the sheets are properly aligned and that there are no gaps or misalignments. Proper clamping or tacking can also help to maintain the correct position of the sheets during welding. 3. Controlling the heat input is essential to prevent excessive distortion. Use the appropriate welding technique, such as TIG or MIG, to control the heat. Avoid overheating the stainless steel sheets, as this can lead to warping and distortion. It is important to maintain a consistent and controlled heat input throughout the welding process. 4. Plan the weld sequence properly to minimize distortion. Start from the center and work outward in a balanced manner to distribute the heat evenly. This will prevent localized heating, which can cause distortion. Alternating between sides and allowing each weld to cool before moving to the next one can also help reduce distortion. 5. Choose the right welding technique and parameters. For example, using a lower heat input, slower travel speed, and smaller weld bead can minimize distortion. Additionally, using a backstep technique, where the weld travels in a forward and backward motion, can help distribute the heat and reduce distortion. 6. Consider preheating the stainless steel sheets to reduce the temperature gradient and minimize distortion. Ensure that the preheating temperature is within the recommended range for the specific stainless steel grade. After welding, it is advisable to perform post-weld treatment, such as stress relieving, to minimize residual stresses that can lead to distortion. By following these steps and precautions, it is possible to significantly reduce distortion when welding stainless steel sheets. However, it is important to note that each welding process and stainless steel grade may have specific requirements. Therefore, it is recommended to refer to the manufacturer's guidelines and seek professional advice for optimal results.

- Q: Can stainless steel sheets be used in outdoor environments?

- Stainless steel sheets are indeed applicable for outdoor settings. Given their exceptional resistance to corrosion, stainless steel proves to be an ideal material for outdoor uses. It can endure tough weather conditions like rain, sunlight, and temperature changes without any degradation. Moreover, stainless steel is resistant to rust, staining, and oxidation, which further amplifies its appropriateness for outdoor utilization. Consequently, stainless steel sheets have garnered widespread popularity in a range of outdoor applications such as construction, architecture, signage, and outdoor furniture.

- Q: How do I calculate the strength of stainless steel sheets?

- To calculate the strength of stainless steel sheets, you need to consider several factors such as the material's tensile strength, yield strength, and elongation. Tensile strength refers to the maximum amount of stress a material can withstand before breaking. It is usually measured in pounds per square inch (psi) or megapascals (MPa). To determine the tensile strength of stainless steel sheets, you can refer to the material's specification sheet provided by the manufacturer or consult engineering handbooks. Yield strength, on the other hand, represents the stress at which a material begins to deform permanently. It is an important parameter to consider when designing structures or selecting materials. The yield strength of stainless steel sheets can also be found in the material's specification sheet or engineering references. Elongation, commonly expressed as a percentage, indicates the extent to which a material can stretch or deform before breaking. Higher elongation values suggest greater ductility. The elongation of stainless steel sheets can be determined through tensile testing or obtained from material specifications. These three parameters - tensile strength, yield strength, and elongation - provide insight into the overall strength and performance of stainless steel sheets. It is essential to consider these factors when evaluating the suitability of stainless steel sheets for specific applications or designing structures that require a particular strength level.

- Q: What are the cost considerations when purchasing stainless steel sheets?

- When purchasing stainless steel sheets, there are several cost considerations to keep in mind. Firstly, the grade of stainless steel will greatly impact the cost. Stainless steel is available in various grades, with each grade possessing different properties and levels of corrosion resistance. Higher grades such as 316 or 304 tend to be more expensive due to their superior corrosion resistance and durability. The size and thickness of the stainless steel sheets also affect the cost. Thicker sheets generally cost more than thinner ones, and larger sheets will be priced higher than smaller ones. It is important to accurately determine the required size and thickness to avoid unnecessary expenses. Surface finish is another factor that can influence the cost. Stainless steel sheets come in a range of finishes, such as brushed, mirror, or matte. Finishes that require additional processing or polishing will usually add to the overall cost. Additionally, the quantity of sheets needed can impact pricing. Bulk purchases often offer discounts or lower per-unit costs compared to buying small quantities. Transportation and delivery costs should also be considered. Stainless steel sheets are heavy and can be expensive to transport, especially if shipping long distances. It is important to factor in these costs to ensure the overall purchase remains within budget. Lastly, it is crucial to consider the reputation and reliability of the supplier. While lower-priced options may be tempting, it is important to ensure that the supplier provides high-quality stainless steel sheets that meet the required specifications. Purchasing from a reputable supplier may come at a slightly higher cost, but it guarantees the quality and reliability of the product. Overall, when purchasing stainless steel sheets, it is vital to consider the grade, size, thickness, surface finish, quantity, transportation costs, and the reputation of the supplier. By carefully considering these factors, one can make an informed decision that balances cost-effectiveness with the desired quality and specifications.

- Q: What are the specifications of stainless steel plates? Are they the same width?

- Generally look at the thickness of 0.3-3.0mm, width of 1000/1219/1500. Thickness of 3 or more, with 1240/1250/1500/1800/2000 width. It can be cut as required.... So the purchase is still more flexible.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC systems. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it an ideal material for HVAC components such as ductwork, heat exchangers, and exhaust systems. It is also durable and easy to clean, ensuring long-lasting performance in HVAC applications.

- Q: What are the different sizes available for stainless steel sheets?

- Stainless steel sheets are available in a wide range of sizes to cater to various applications and requirements. The most common sizes for stainless steel sheets are typically 4 feet by 8 feet (1219mm x 2438mm) and 4 feet by 10 feet (1219mm x 3048mm). These sizes are widely used in construction, architecture, and industrial settings. However, stainless steel sheets are also available in smaller sizes, such as 2 feet by 4 feet (609mm x 1219mm) or even smaller, which are commonly used for DIY projects, hobbyists, and smaller-scale applications. On the other hand, larger sizes of stainless steel sheets are also available for specific purposes. These can include sheets measuring up to 5 feet by 10 feet (1524mm x 3048mm) or even larger, which are often used in specialized industries like shipbuilding, oil and gas, or manufacturing. It is important to note that the thickness of stainless steel sheets can vary independently of their size, as different applications may require different thicknesses. Common thicknesses range from 0.025 inches (0.64mm) to 0.1875 inches (4.76mm) or even thicker for specialized applications. Overall, the availability of stainless steel sheets in various sizes allows for flexibility and customization according to the specific needs of a project, whether it be a small DIY endeavor or a large-scale industrial application.

- Q: How do you determine the grade of a stainless steel sheet?

- Multiple factors must be taken into account in order to determine the grade of a stainless steel sheet. Firstly, it is necessary to analyze the composition of the stainless steel. Stainless steel is typically composed of a combination of metals, including iron, chromium, nickel, and other elements. The specific percentages of these metals will dictate the grade of the stainless steel. For example, a stainless steel sheet with higher levels of chromium and nickel will generally have a higher grade. The mechanical properties of the stainless steel are also an important consideration. These properties encompass the tensile strength, yield strength, and elongation of the material. Different grades of stainless steel will exhibit varying mechanical properties, which can be assessed using standardized testing methods. Surface finish is another factor that contributes to determining the grade of a stainless steel sheet. The finish can range from rough and dull to smooth and polished. Specific surface finishes may be associated with different grades of stainless steel, and this can be confirmed through visual inspection or the use of specialized equipment. Furthermore, the corrosion resistance of the stainless steel sheet plays a significant role in its grade determination. Stainless steel is renowned for its resistance to corrosion, and higher grades of stainless steel generally offer superior resistance to various corrosive environments. Corrosion testing methods, such as salt spray testing, can aid in evaluating the corrosion resistance of a stainless steel sheet. In conclusion, the grade of a stainless steel sheet can be determined by analyzing its composition, mechanical properties, surface finish, and corrosion resistance. By considering these factors, one can accurately ascertain the grade of a stainless steel sheet and assess its suitability for specific applications.

- Q: What are the different types of finishes available for stainless steel sheets?

- There are several different types of finishes available for stainless steel sheets, each offering its own unique appearance and level of protection. Some of the most common finishes include: 1. No. 1 Finish: This is a dull, rough, and non-reflective finish that is achieved by hot rolling the stainless steel sheet. It is commonly used for industrial applications where appearance is not a primary concern. 2. No. 2B Finish: This finish is a smooth, reflective surface achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It is widely used in applications that require a visually appealing finish, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this is achieved by applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is commonly used for architectural and decorative purposes. 4. No. 8 Finish: This is a highly reflective finish that is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is often used in applications where a sleek and sophisticated look is desired, such as in high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is achieved by annealing the stainless steel sheet in a controlled atmosphere and then pickling or blasting it to remove any oxide scale. It results in a smooth, bright surface that is commonly used in applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: This finish is achieved by mechanically brushing the surface of the stainless steel sheet with fine abrasive belts. It creates a subtle, textured look that can be used for architectural and decorative purposes. 7. Embossed Finish: This finish involves imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is often used in applications such as elevator interiors, wall cladding, and signage. These are just a few of the many finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The choice of finish depends on the specific application and desired appearance.

Send your message to us

200 300 Series Grade 2B Stainless Steel Sheet Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords