2 6 Aluminum Sheets - Alloy 8011/1100 Flat Aluminum Sheet for Circuit Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy 8011/1100 Flat Aluminum Sheet for Circuit Board

l Product Introduction

Aluminium has a lot of salient properties that the other metals do not have. It is very strong, yet it is not very heavy. Like other metals, it conducts electricity and heat to a moderate degree. Most industries require aluminium sheets for various purposes. Aluminium can be easily beaten into sheets because of its high malleability. It has the preoperty of light weight, medium strength, easy-forming and anti-corrosion.

l Product Description

| Decorative Coil/Plate | ||

| Alloy: | 1100/8011/3003 | |

| Temper: | H16/H18/H26 | |

| Thickness: | 0.10mm~0.50mm | |

| Width: | 1000mm--1300mm | |

| Tensile Strength: | 155~230Mpa | |

| Elongation: | ≥2.0% | |

| T Bend: | within 2T | |

| PS Board Base | ||

| Alloy: | 1060 | |

| Temper: | H18 | |

| Thickness: | 0.14mm~0.27mm | |

| Width: | 300--1250mm | |

| Tensile Strength: | ≥140Mpa | |

| Elongation: | ≥2.0% | |

| Circuit/Lighting sheet | ||

| Alloy: | 1060/1100/8011/1050 | |

| Temper: | H16/H18 | |

| Thickness: | 0.14mm~0.50mm | |

| Width: | 300--1250mm | |

| Tensile Strength: | 165~195Mpa | |

l Packaging & Delivery

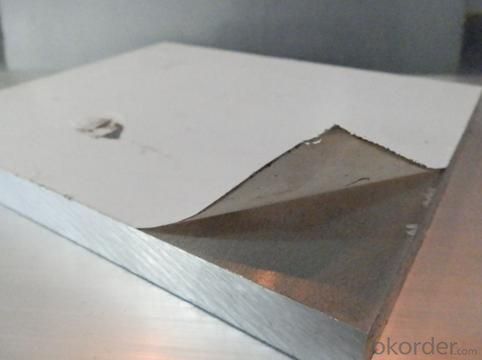

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

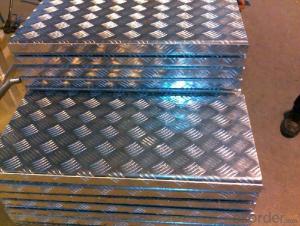

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Are 101 aluminum sheets suitable for chemical processing equipment?

- Chemical processing equipment should not employ 101 aluminum sheets due to their unsuitability. Although aluminum is a versatile and extensively utilized material, its use is not advisable when dealing with potent acids or bases. Aluminum is prone to corrosion when exposed to certain chemicals, jeopardizing the equipment's integrity and potentially causing leaks or other safety risks. Therefore, it is advisable to opt for materials explicitly engineered and produced to endure the corrosive impacts of the chemicals employed in chemical processing equipment.

- Q: Can aluminum sheet be used for medical applications?

- Yes, aluminum sheet can be used for certain medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various medical devices and equipment. For example, aluminum sheets can be used for manufacturing prosthetic limbs, braces, and orthopedic implants. Additionally, aluminum can be used in the production of medical instruments, such as surgical trays, sterilization containers, and imaging equipment. However, it is important to note that aluminum may not be suitable for all medical applications, as certain medical devices may require specific properties or materials to meet regulatory standards and ensure patient safety. Therefore, the use of aluminum sheet in medical applications should be determined on a case-by-case basis, considering the specific requirements and regulations of each application.

- Q: What are the different methods of surface coating for aluminum sheets?

- There are various methods of surface coating available for aluminum sheets, each offering unique benefits and applications. Some of the most commonly used methods include: 1. Anodizing: This process involves creating a protective oxide layer on the surface of the aluminum by immersing it in an electrolytic solution. Anodizing provides enhanced corrosion resistance, improved durability, and can also be used to achieve decorative finishes. 2. Powder coating: Powder coating involves applying a dry powder onto the surface of the aluminum and then curing it through a heating process. This method provides a durable and attractive finish, with excellent resistance to abrasion, chemicals, and UV rays. 3. Painting: Aluminum sheets can be coated with conventional liquid paints to achieve various colors and finishes. This method allows for customization and offers good corrosion protection, but may not be as durable as other methods. 4. Cladding: Cladding involves bonding a protective layer, such as stainless steel or other metals, onto the surface of the aluminum sheet. This method provides superior protection against corrosion, impact, and extreme weather conditions. 5. Laminating: Laminating involves applying a thin layer of protective material, such as PVC or PET film, onto the surface of the aluminum sheet. This method enhances the sheet's resistance to scratching, staining, and fading, making it suitable for applications requiring long-term durability. 6. Chemical conversion coating: This method involves treating the aluminum surface with a chemical solution to create a thin, protective layer. Chromate conversion coating, for example, enhances corrosion resistance and improves paint adhesion. 7. Electrophoretic deposition (EPD): EPD involves immersing the aluminum sheet in a water-based paint solution and applying an electric current to deposit the paint particles onto the surface. This method provides uniform coating thickness and excellent corrosion resistance. Each of these surface coating methods offers specific advantages and is suited for different applications. Choosing the appropriate method depends on the desired properties, aesthetics, and the intended use of the aluminum sheets.

- Q: What are the standards and certifications available for aluminum sheets?

- Aluminum sheets can be evaluated for quality and compliance with industry requirements through various standards and certifications. Some well-known ones include: 1. ASTM International Standards: Developed by the American Society for Testing and Materials (ASTM), these standards focus on aspects like chemical composition, mechanical properties, and dimensional tolerances. They promote consistent quality across different aluminum sheet products. 2. ISO 9001: This globally recognized certification establishes guidelines for quality management systems. Aluminum sheet manufacturers with ISO 9001 certification demonstrate their commitment to meeting customer requirements, continuous improvement, and strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has established a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency in the European market. 6. RoHS Compliance: Compliance with the Restriction of Hazardous Substances (RoHS) is crucial for aluminum sheets used in electrical and electronic equipment. This certification guarantees that the aluminum sheets are free from hazardous substances, ensuring environmental safety. Manufacturers and suppliers of aluminum sheets must adhere to these standards and certifications to ensure their products are of the highest quality, safety, and suitability for specific applications.

- Q: And isn't aluminum extremely bad for ones health?

- it's okorder

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum sheet size available for aluminum sheets varies depending on the specific supplier and manufacturer. However, commonly available sheet sizes for aluminum range from 4 feet by 8 feet (1219mm x 2438mm) to 5 feet by 10 feet (1524mm x 3048mm).

- Q: Can aluminum sheets be used for signage purposes?

- Yes, aluminum sheets can be used for signage purposes. They are commonly chosen for outdoor signs due to their durability, weather resistance, and lightweight nature. Aluminum sheets can be easily customized, printed on, and shaped to create professional and long-lasting signage.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, aluminum sheets can be used for green building materials. They are lightweight, durable, and have high recyclability, which reduces waste. Aluminum is also energy-efficient in production and use, and its reflective properties can help in reducing heat absorption, thus lowering cooling costs. Additionally, aluminum's resistance to corrosion and weathering means it requires less maintenance, contributing to its sustainability in green building practices.</p>

- Q: This question asks for criteria or factors to consider when selecting a high-quality aluminum sheet.

- <p>To choose a quality aluminum sheet, consider the following factors: 1) Thickness and weight, which should meet your specific project requirements. 2) Surface finish, ensuring it's smooth and free from defects. 3) Purity and alloy type, as different alloys have different properties. 4) Certifications, ensuring the sheet meets industry standards. 5) Supplier reputation and customer reviews for reliability. 6) Price, ensuring it's reasonable for the quality. 7) Conductivity and strength, depending on your application. 8) Corrosion resistance, important for longevity. Always inspect the sheet for any visible defects and ensure it's from a reputable supplier.</p>

- Q: What are the different types of alloys used in aluminum sheets?

- Aluminum sheets utilize a variety of alloys, each possessing distinct properties and advantages. The following are some commonly employed alloys: 1. The 3003 alloy offers exceptional formability, corrosion resistance, and weldability, making it suitable for general-purpose use. It finds applications in cooking utensils, signage, and chemical equipment. 2. Known for its high strength and good corrosion resistance, the 5052 alloy is frequently utilized in marine and automotive fields. It is also employed in sheet metal fabrication and structural components. 3. The 6061 alloy is highly versatile and finds application in several sectors such as aerospace, automotive, and structural components. It provides excellent strength, machinability, and weldability. 4. Primarily used in aerospace and high-strength applications, the 7075 alloy boasts an exceptional strength-to-weight ratio. It is commonly employed in aircraft fittings, gears, and bike frames. 5. The 2024 alloy, popular in aerospace applications, exhibits a high strength-to-weight ratio and excellent fatigue resistance. It is commonly used for aircraft structures, bolts, and rivets. 6. The 5083 alloy, specifically designed for marine applications, showcases outstanding corrosion resistance and high strength. It is frequently utilized for boat hulls and structural components. These are merely a few instances of the diverse alloys employed in aluminum sheets. Each alloy possesses a unique combination of properties that enable it to excel in specific applications.

Send your message to us

2 6 Aluminum Sheets - Alloy 8011/1100 Flat Aluminum Sheet for Circuit Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords