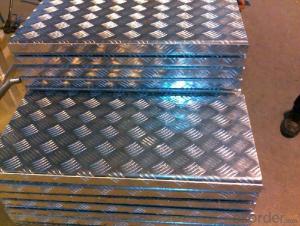

Aluminum Foil Ball Dryer Aluminum Sheet Alloy 8011/1100 Flat for Circuit Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | wooden cases is suitable for long distance exporting. |

| Delivery Detail: | 30-45 days after receiving L/C or payment in advance |

| Decorative Coil/Plate | ||

| Alloy: | 1100/8011/3003 | |

| Temper: | H16/H18/H26 | |

| Thickness: | 0.10mm~0.50mm | |

| Width: | 1000mm--1300mm | |

| Tensile Strength: | 155~230Mpa | |

| Elongation: | ≥2.0% | |

| T Bend: | within 2T | |

| PS Board Base | ||

| Alloy: | 1060 | |

| Temper: | H18 | |

| Thickness: | 0.14mm~0.27mm | |

| Width: | 300--1250mm | |

| Tensile Strength: | ≥140Mpa | |

| Elongation: | ≥2.0% | |

| Circuit/Lighting sheet | ||

| Alloy: | 1060/1100/8011/1050 | |

| Temper: | H16/H18 | |

| Thickness: | 0.14mm~0.50mm | |

| Width: | 300--1250mm | |

| Tensile Strength: | 165~195Mpa | |

| Elongation: | ||

Brief Introduction for Cold Rolled Steel Coil

Cold Rolled Steel Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final Cold Rolled Steel Coil may be manufactured in the form of sheets, strips, bars, or other forms.

Photos

- Q: We did this lab with lead originally by taking out lead with a magnet, subliming ammonium chloride, and then decanting sand and saltOur lab report requires that we explain how this process would be different if aluminum was used instead of the leadPlease help! We are all stumped.

- Mix it with water, then filter itYou'll get the salt and the ammonium chloride in solution and the aluminium and sand in the filter paper To seperate the salt from the ammonium chloride, evaporate off the water, then redissolve it in methanolThe sodium chloride will dissolve in it, whereas the ammonium chloride won'tSeperate them by filtrationIt's not perfect, but it should get most of it seperatedTo seperate the aluminium from the sand, mix it with hydrochloric acid, which should convert the aluminium to aluminium chloride, which will dissolve in the acidFilter it to seperate the sand, then you can regenerate the aluminium from the aluminium chloride solution by electrolysis.

- Q: There is a book called Holy Enchilada and in the back of the book is a recipe for enchiladasCan someone give me it ? Thanks!

- Ham by its nature is a precooked foodIt only needs heated if that is the way you want it or it can be sliced and served chilled.

- Q: this energizer battery's aluminum kinda paper thing was peeling and i just ripped off it still works and stuff but i wanna know if its safe or anything or is like ripping of the label on a water bottle

- I think you get a pretty good buzz, but I forget.

- Q: In the lab, we created a quot;batteryquot; by using aluminum foil, a paper towel, a penny, and vinegar, which was then measured by a voltmeterEverything worked fine, and eventually we managed to get it to generate a chargeHowever, one - actually two of the questions stumped me a littleI honestly don't understand the concept at ALLHere are the two questions:1) Suppose you were to cover your penny with a paper towel soaked in vinegar and then added an identical stack of aluminum, paper towel soaked in vinegar, and pennyIf you touched one lead on the bottom piece of aluminium foil and one lead on the top penny, what reading would you expect on the voltmeter? Explain.2) What is another question about electrochemical cells that you could investigate using these materials?Please also explain your answer so I can potentially grasp a better understanding of thisThanks in advance.

- Off the cuff ,Hydrogen when dissociated creates a 33,000lb pressure,momentarily,and doubles in size.When vibrating at 17,480 very little electric current is necessary to dissociate Hydrogen gas from water.

- Q: ok so i was making this candy, chocolate chip nougat log from the hersheys cookbookits made mostly of cornstarch sugar mixed together on the stovei poured it in the pan, which i had covered in foilthis morning, when i tried to take it out, i realized i had forgotten to put butter on the foilwhen i try to peel it off, the foil just rips since the candy is VERY VERY stickyis there any way i can fix this?? i really need to get the foil off!thanks for any help u can give me!

- This is really toughThis actually happened to me once (small world, huh? haha)But I'm lucky enough to have a small propane torchJust flip the candy/foil over and run the torch over itThat melts the candy a little and the foil will come offBut if you don't have a torch, then the only other thing I can think of would be either try this with a gas stove (not sure how that would work, and chances are better that you would end up burning yourself.), or just cut off the sides of the stuff and just lose some of the nougat to the foil.

- Q: Does anyone have a home made mixture for cleaning silver? Nothing I have works at all.?

- First - dsada d - if you want to ask a question you should ask in the proper format - not do it on someone else's answer pageIf you are using all the right products, I would suggest a cut (you probably need more than just a trim at this point if your hair is really damaged - a good inch at least)Then if you want to continue straightening it make sure you get a trim every 6 weeks or so to keep the damaged ends at bayBeware of any product that claims to repair damaged hair, it is just full of wax and is going to coat your hair in the stuff and you will end up with more damage I am in the same situation as you, my hair is curly but I love it straight, so I've had to compromiseI only straighten it once in awhile, and have searched for products to make my curly hair look better (Aveda's curly line is great)If you get a cut that suits your curliness, you may be happier with itI think the key is to find a good stylist that really knows your hair type Good luck!

- Q: What mass of aluminum has a total nuclear charge of 2.6 C? Aluminum has atomic number 13Suppose the aluminum is all of the isotope with 14 neutrons.Express your answer with the appropriate units.

- Thank you very very much!! I can now understand the way this should be solved :D Thank you also for the steps!!

- Q: I need to find uses of the natural isotopes of aluminum, and i can't find anything about aluminum-27!!!

- Aluminum 27 is the naturally occurring isotope of aluminum, so when you see anything that has aluminum in it, it will have essentially all aluminum-27. Aluminum-26 is strictly a trace isotope.

- Q: Even though there's wasted space when packing cylindrical cans in shipping boxes, why does the shape make sense?

- Why don't you just ask your doctor? The person that diagnosed you with this condition.

Send your message to us

Aluminum Foil Ball Dryer Aluminum Sheet Alloy 8011/1100 Flat for Circuit Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords