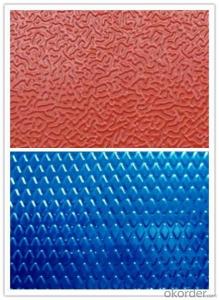

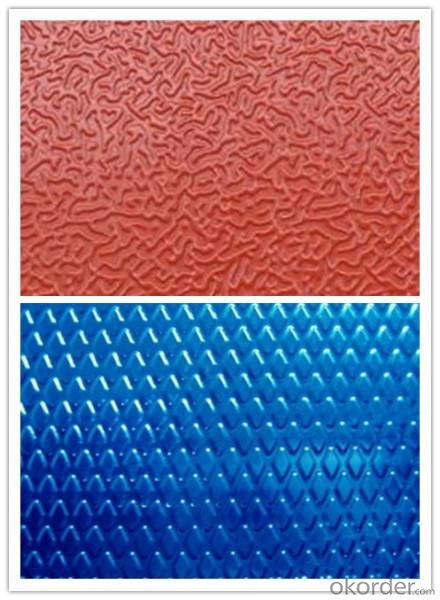

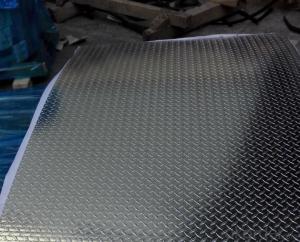

1mm Aluminum Sheets for Sale - 1100 3003 5052 5754 5083 6061 7075 Non-Slip Alloy Embossed Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packing

Export packaging fumigation chassis, plank packing paper, coil diameter 1.1- 1.14 meters, 508 sof-core, 90 degree bending cracks. Single package weigh of coil is 1.5 -2 metic tons, coil is 3-5.7 metric tons .

1000 series aluminum coil is a commercially pure aluminum.

Excellent welding characteristics,Excellent ductile property,Excellent resistance to corrosion,Excellent conductivity.

Application of 1000 series aluminum coil,Chemical and food processing industries,Giftware material,Eye-appeal necessity needed material,Curtain wall material,Cookware material,Nameplate material,Decorative and reflective material,3000 series aluminum coil is a commercially pure aluminum with the addition of manganese. Good corrosion resistance,Excellent weldability,formability,Good corrosion resistance,Moderate strength,Specially, 3104 aluminum alloy is a typical deep-drawing material.

Application of 3000 series aluminum coil,Cooking and kitchen equipment,Decorative trim,Food & Chemical processing and storage container,Tank container,Pressure vessel,Cooling fin,Deep drawing processing material. 5000 series Aluminum coil is a typical Al-Mg aluminum product. High stength, Good salt water resistance, Good low temperature ressistance.

We have advanced equipment in the factory. Neat factory mill, advanced machines and skilled workers enable to manufacture high quality products.

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: This question asks for methods to determine if a building is utilizing high-quality aluminum sheets.

- <p>To determine if a building is using high-quality aluminum sheets, look for the following characteristics: the sheets should have a uniform and smooth surface without visible defects or impurities. Check for a strong and consistent thickness throughout the material. High-quality aluminum is also resistant to corrosion and should not show signs of rust or pitting. Additionally, the sheets should be lightweight yet rigid, indicating a high strength-to-weight ratio. You can also inquire about the manufacturer's specifications and certifications, as reputable suppliers will provide detailed information about the quality and composition of their aluminum sheets.</p>

- Q: Can aluminum sheets be embossed or textured?

- Yes, aluminum sheets can be embossed or textured. The process of embossing or texturing aluminum sheets involves creating patterns or designs on the surface by pressing or rolling the sheet with specialized machinery. This can be done to enhance the aesthetic appearance of the sheet or to improve its functionality, such as adding grip or increasing strength. Embossed or textured aluminum sheets are commonly used in various industries, including automotive, interior design, and packaging.

- Q: What is the surface hardness of aluminum sheets?

- The surface hardness of aluminum sheets can vary depending on the alloy and treatment process. Generally, aluminum sheets have a relatively low surface hardness compared to other metals such as steel or titanium. However, certain aluminum alloys can be heat-treated to improve their hardness. For example, 6061-T6 aluminum sheets have a surface hardness of around 95 Brinell, while 7075-T6 aluminum sheets have a surface hardness of approximately 150 Brinell. It is important to note that these values are approximate and can vary depending on the specific alloy, temper, and processing conditions.

- Q: Are aluminum sheets resistant to impact?

- Yes, aluminum sheets are generally resistant to impact due to their high strength-to-weight ratio and ability to absorb and distribute energy.

- Q: Are the aluminum sheets suitable for manufacturing solar panel backings?

- Yes, aluminum sheets are suitable for manufacturing solar panel backings. Aluminum is a widely used material in the solar industry due to its excellent properties. It is lightweight, durable, and corrosion-resistant, making it ideal for outdoor applications. Additionally, aluminum has a high thermal conductivity, allowing it to dissipate heat effectively, which is crucial for solar panels to operate efficiently. Furthermore, aluminum is easily recyclable, making it a sustainable choice for solar panel manufacturing. Overall, aluminum sheets are a suitable material for manufacturing solar panel backings.

- Q: Are the aluminum sheets suitable for manufacturing heat exchangers?

- Indeed, aluminum sheets prove to be fitting for the production of heat exchangers. Aluminum, being both lightweight and highly conductive, serves as an ideal option for heat transfer purposes. Its exceptional thermal conductivity facilitates efficient heat transfer, resulting in effective cooling or heating procedures. Moreover, aluminum's resistance to corrosion is of utmost importance for heat exchangers that encounter diverse fluids. Furthermore, the malleability and formability of aluminum sheets render them effortlessly malleable into the required designs for heat exchanger components. On the whole, aluminum sheets offer numerous benefits for the manufacturing of heat exchangers, thus making them a suitable selection for this particular application.

- Q: Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

- Q: Where else besides deodorant can we find aluminum?

- it okorder

- Q: How does aluminum sheet perform in extreme temperatures?

- Aluminum sheet performs exceptionally well in extreme temperatures due to its unique properties. One of the key advantages of aluminum is its high thermal conductivity, which means it can rapidly transfer heat. This property allows aluminum sheet to quickly adjust to extreme temperatures, preventing warping or cracking that can occur with other materials. Additionally, aluminum has a high melting point of around 660 degrees Celsius, making it ideal for applications in high-temperature environments. It remains structurally stable and does not lose its strength or integrity when exposed to extreme heat. Moreover, aluminum has a low coefficient of thermal expansion, meaning it expands and contracts minimally with temperature changes. This characteristic enables aluminum sheet to maintain its shape and dimensions even when subjected to extreme temperature fluctuations. Furthermore, aluminum has excellent corrosion resistance, which is further enhanced by an oxide layer that forms naturally on its surface. This oxide layer protects the aluminum from chemical reactions and prevents it from deteriorating even in harsh environments or extreme temperatures. In summary, aluminum sheet performs exceptionally well in extreme temperatures due to its high thermal conductivity, high melting point, low coefficient of thermal expansion, and excellent corrosion resistance. These properties make it a reliable choice for various applications, including aerospace, automotive, and industrial sectors, where performance under extreme temperatures is crucial.

Send your message to us

1mm Aluminum Sheets for Sale - 1100 3003 5052 5754 5083 6061 7075 Non-Slip Alloy Embossed Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords