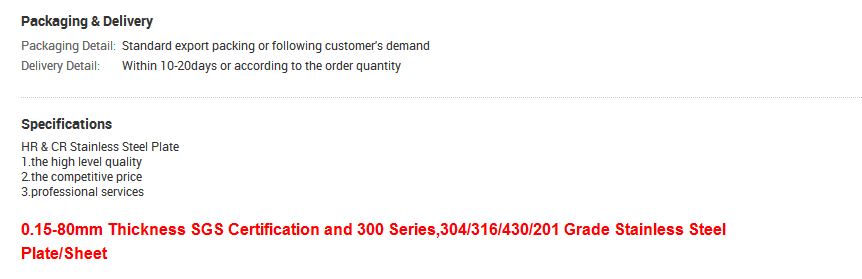

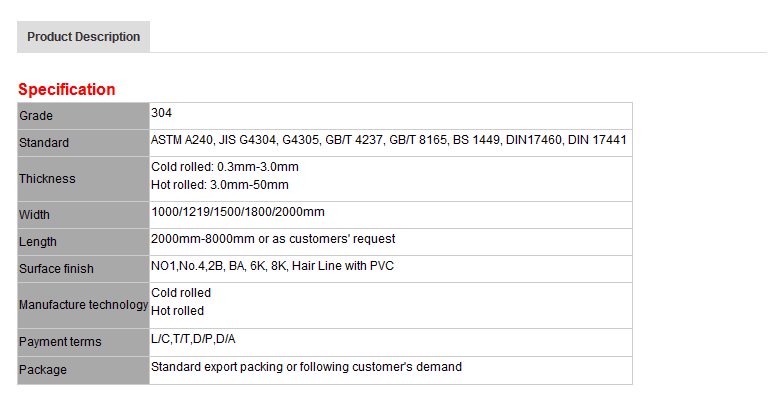

0.15-80mm Thickness SGS Certification and 300 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What are the different types of stainless steel pipe bends?

- There are several different types of stainless steel pipe bends, including 45-degree, 90-degree, and 180-degree bends. Additionally, there are short radius and long radius bends, as well as U-bends and J-bends. These variations allow for flexibility in designing and connecting stainless steel piping systems to fit specific needs and spatial constraints.

- Q: Can stainless steel pipes be coated with other materials?

- Coating stainless steel pipes with different materials is indeed possible. It is a widely adopted practice across diverse industries. The aim behind this coating procedure is to elevate their performance, safeguard against corrosion, enhance visual appeal, or provide supplementary functionalities. Epoxy, polyethylene, PVC, zinc, or ceramic coatings are some of the commonly employed materials for coating stainless steel pipes. These coatings offer numerous advantages, including heightened resistance to corrosion, improved resistance against abrasion, enhanced insulation properties, or diminished friction. The process of coating stainless steel pipes with other materials is typically carried out through techniques like electroplating, hot-dipping, or powder coating. The selection of the coating material and process hinges upon the specific requirements and intended application of the stainless steel pipes.

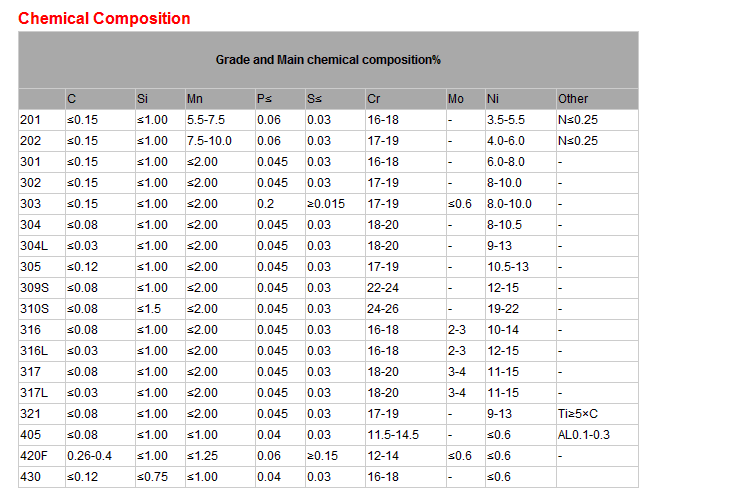

- Q: What is the difference between 321 and 316 stainless steel pipes?

- The main difference between 321 and 316 stainless steel pipes lies in their chemical composition and intended applications. 321 stainless steel pipes contain titanium, which stabilizes the material against chromium carbide formation. This makes it highly resistant to intergranular corrosion, even at elevated temperatures. As a result, 321 stainless steel pipes are commonly used in applications where high temperatures are involved, such as in the aerospace and power generation industries. On the other hand, 316 stainless steel pipes do not contain titanium but have molybdenum in their composition. This addition enhances the material's corrosion resistance, particularly in environments with chloride ions, making it suitable for applications in marine and coastal environments. Additionally, 316 stainless steel pipes are often used in the food and beverage industry due to their excellent resistance to acids and chemicals. In summary, while both 321 and 316 stainless steel pipes offer excellent corrosion resistance, the presence of titanium in 321 stainless steel pipes provides enhanced resistance to intergranular corrosion at high temperatures, whereas the addition of molybdenum in 316 stainless steel pipes improves their resistance to chloride-based corrosion in marine and coastal environments.

- Q: Can stainless steel pipes be insulated with foam?

- Yes, stainless steel pipes can be insulated with foam. Foam insulation is commonly used to insulate pipes of various materials, including stainless steel. Foam insulation provides thermal resistance and helps to prevent heat loss or gain from the pipes. It also helps to minimize condensation on the surface of the pipes, which can prevent corrosion. Foam insulation can be easily applied to stainless steel pipes using adhesive or tape, and it can be customized to fit the specific dimensions of the pipes. Overall, foam insulation is an effective and cost-efficient solution for insulating stainless steel pipes.

- Q: What is the difference between 17-4PH and 15-5PH stainless steel pipes?

- The main difference between 17-4PH and 15-5PH stainless steel pipes lies in their chemical compositions and mechanical properties. 17-4PH stainless steel contains about 17% chromium, 4% nickel, and 4% copper. It also includes small amounts of molybdenum and niobium. This composition gives it excellent corrosion resistance, high strength, and good toughness. It is commonly used in applications that require high strength, such as aerospace components, oil and gas equipment, and marine applications. On the other hand, 15-5PH stainless steel contains about 15% chromium, 5% nickel, and 3% copper. It also includes small amounts of molybdenum and niobium. This composition provides good corrosion resistance, high strength, and excellent toughness. It is often used in applications that require a combination of strength and corrosion resistance, such as valves, pumps, and shafts. In summary, while both 17-4PH and 15-5PH stainless steel pipes have similar corrosion resistance and high strength, their specific compositions and properties may make them more suitable for different applications.

- Q: Can stainless steel pipes be insulated with polylactic acid?

- Polylactic acid (PLA) can be used to insulate stainless steel pipes. PLA, a biodegradable thermoplastic polymer, is derived from renewable sources like corn starch or sugar cane. Due to its low thermal conductivity and insulation properties, PLA is commonly used as an insulation material. To insulate stainless steel pipes with PLA, simply apply a layer of PLA insulation around the pipes. This insulation layer helps reduce heat loss or gain, prevent condensation, and improve energy efficiency. PLA insulation can be in the form of sheets or tubes, making it easy to wrap around the pipes. One advantage of using PLA insulation is its eco-friendly nature. It is biodegradable and does not release harmful toxins during production or disposal. PLA is also sustainable as it can be derived from renewable resources. Moreover, PLA insulation is moisture-resistant and dimensionally stable, making it suitable for various applications. However, it is important to note that PLA has a lower melting point compared to stainless steel. Therefore, it may not be suitable for high-temperature applications. For extreme heat exposure, it is recommended to consider alternative insulation materials with higher melting points. In conclusion, PLA insulation is an effective option for insulating stainless steel pipes. It offers good thermal properties, is environmentally friendly, and contributes to energy savings. However, it is crucial to consider the temperature limits of PLA when using it for insulation purposes.

- Q: What is the difference between electropolished and bright annealed stainless steel pipes?

- Electropolished and bright annealed stainless steel pipes are two different surface treatments applied to stainless steel pipes to enhance their properties and appearance. Electropolishing is an electrochemical process that removes a thin layer of material from the surface of the stainless steel pipe. This process helps to remove any impurities, contaminants, or roughness on the surface, resulting in a smooth and highly polished finish. Electropolishing also improves the corrosion resistance of stainless steel by creating a passive oxide layer on the surface, which helps to protect the underlying material from corrosion. On the other hand, bright annealing is a heat treatment process that involves heating the stainless steel pipe to a specific temperature and then cooling it slowly in a controlled atmosphere. This process helps to relieve internal stresses, improve the ductility and toughness of the material, and enhance its mechanical properties. Bright annealing also produces a smooth and reflective surface finish, similar to electropolishing, but without the electrochemical removal of material. In summary, the main difference between electropolished and bright annealed stainless steel pipes lies in the process used to achieve the desired surface finish. Electropolishing involves the removal of material through an electrochemical process, while bright annealing is a heat treatment process that provides a smooth and reflective surface without removing material. Both treatments improve the appearance and corrosion resistance of stainless steel pipes, but bright annealing also enhances the mechanical properties of the material.

- Q: Are stainless steel pipes suitable for solar power systems?

- Stainless steel pipes prove themselves as a suitable option for solar power systems. Their exceptional resistance to corrosion, a renowned characteristic of stainless steel, renders them an optimal choice for solar power systems that encounter diverse weather conditions. The transportation of fluids, such as water or heat transfer fluids, often arises as a necessity in solar power systems, and stainless steel pipes effectively cater to these requirements. Additionally, the durability and prolonged lifespan of stainless steel pipes ensure the longevity and efficiency of the solar power system. Moreover, stainless steel, being a sustainable and environmentally friendly material, harmonizes well with the renewable energy objectives of solar power systems. In conclusion, stainless steel pipes emerge as a dependable and appropriate selection for solar power systems.

- Q: Can stainless steel pipes be used for irrigation sprinkler systems?

- Indeed, irrigation sprinkler systems can utilize stainless steel pipes. Renowned for their durability, strength, and resistance to corrosion, stainless steel pipes prove to be an exceptional preference for irrigation setups. They possess the ability to endure high water pressure and are less prone to rust or decay over time in comparison to alternative materials, such as PVC or galvanized steel. Furthermore, stainless steel pipes guarantee hygienic conditions and do not taint the water supply, rendering them a secure choice for irrigation systems. Nevertheless, it remains crucial to take into account factors like cost and compatibility with existing infrastructure prior to opting for stainless steel pipes in irrigation sprinkler systems.

- Q: Are stainless steel pipes suitable for fertilizer production?

- Yes, stainless steel pipes are suitable for fertilizer production. Stainless steel pipes offer a number of advantages that make them a preferred choice for use in the fertilizer industry. Firstly, stainless steel pipes are highly resistant to corrosion, which is particularly important in the production of fertilizers. Fertilizer production involves the use of chemicals and substances that can be highly corrosive, such as ammonia, sulfuric acid, and phosphoric acid. Stainless steel pipes can withstand the corrosive effects of these substances, ensuring the integrity and longevity of the piping system. Additionally, stainless steel pipes have excellent strength and durability, making them able to withstand the high pressures and temperatures often encountered in fertilizer production processes. This ensures the safe and efficient transportation of the fertilizer materials within the production plant. Furthermore, stainless steel pipes are hygienic and easy to clean, which is crucial for maintaining the purity of the fertilizer products. Stainless steel has a smooth surface that resists the buildup of bacteria, dirt, and other contaminants, ensuring that the pipes do not contaminate the fertilizer during production. Lastly, stainless steel is a sustainable and environmentally friendly material. It is 100% recyclable, making it a more sustainable choice compared to other pipe materials. Additionally, stainless steel has a long lifespan, reducing the need for frequent replacements and minimizing waste. In conclusion, stainless steel pipes are highly suitable for fertilizer production due to their corrosion resistance, strength, durability, hygienic properties, and environmental benefits.

Send your message to us

0.15-80mm Thickness SGS Certification and 300 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords