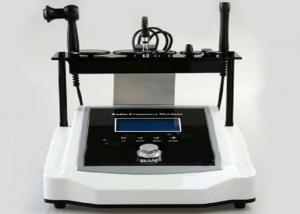

Ultrasonic Plastic Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 80 Pieces per Month set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

plastic welding machine

1.welding round plastic product

2.perfect effect, air-tight and water-tight

3.custom making is ok

quality plastic welding machine, weld round plastic items

1.for welding round plastic product

2.easy maintenance

3.perfect effect, air-tight and water-tight

4.custom making is welcome

5.made of quality stainless steel

Applications:

to weld any round plastic, globe plastic item, such as kettle, ball, float ball, bucket, cup, thermos shell etc

- Q:What's the difference between ultrasonic plastic welding machine and ultrasonic plastic hot melt machine?

- It's all one thing

- Q:What are the causes of the high power transistors in ultrasonic plastic welding machines?

- The driving signal drives the high power triode (IGBT) to work at high frequency (hard switching), which is susceptible to interference (mainly high-frequency)

- Q:How many kinds of ultrasonic welding machine power are there?

- Single machine can do 200W - 5600W ultrasonic welding machine.

- Q:Please describe in detail the 2015 mould material manufacturing process, pay attention to the problem, the relevant difficult solution

- To do ultrasonic mold of the same product, method of making diversification (material is usually Aluminum Alloy / titanium alloy / steel is also useful; and as the shape but round / square / combination and so on, are different), I can't say this two can let everyone know (because the design of ultrasonic mold needs the knowledge, such as: material mechanics / acoustic / wave, etc.) but must have the ultrasonic testing equipment to ensure the quality of ultrasonic mold.

- Q:Ultrasonic plastic welding machine power, the better the better?

- This is not, the quality of the machine is not divided by power, the power of the machine welding more sophisticated products, the effect will be better.

- Q:What does ultrasonic plastic welding machine "15k20k" mean?

- The number of times a work frequency is measured in seconds

- Q:Ultrasonic plastic welding machine die is not durable, what material good?

- Ultrasonic plastic welding machine die is not durable, what material is good?Aluminium alloys (7075, 2024, 6061-T651):7075: generally used in vibration systems and HORN manufacturing, high hardness, thermal conductivity, good toughness.2024: generally used in HORN manufacturing, toughness, heat conductivity, hardness moderate, used in general welding plastic products.6061: generally used in the bottom mold manufacturing or low output of HORN, good toughness, hardness than 2024 times.Two, SCM8: generally used for embedded screws, metal inlay, excellent toughness, high hardness, heat conduction is 2024 times.Three, titanium alloy: generally used for the occasion of continuous vibration, high toughness, good heat conduction, high hardness, but expensive.

- Q:What kind of hot air plastic welding torch and plastic welding machine made in China? Used to weld plastic sheets and tubing

- The quality is imported, the price is expensive, the domestic good should be Wenzhou LANSITE welding equipment factory production of Lansite brand welding gun, plastic welding machines. You can go to Taobao to find out. The heater in their house is good

- Q:How can ultrasonic plastic welding machine replace ultrasonic mould?

- How can ultrasonic plastic welding machine replace ultrasonic mould? First, the ultrasonic transducer horn contact the mold place, with cloth or alcohol wipe clean, followed by ultrasonic, mold a little to tighten!

- Q:Ultrasonic plastic welding machine die wave is not strong, how to repair?

- Isn't there enough frequency?

Our company specializes in the production of ultrasonic cleaning equipment and plastic and metal welding machinery. with general application to electronics, electrical appliances,machinery,metallurgy,textiles,chemicals,toy,clothing,medicine.pharmaceuticals,clocks&watches,jewellery,spectacles,cars,electroplanting,packing and other diverse industrial processes and specializes in producing high quality beauty and health care equipment. There is a group of professional technicians.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China (Mainland) |

| Year Established | 1993 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Ultrasonic Plastic Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 80 Pieces per Month set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords