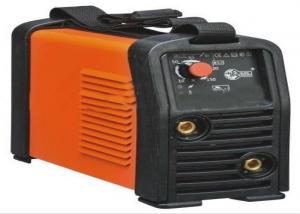

Butt Fusion Machine RDH315

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

RDH315 butt fusion machine

1. welding range : from 160mm~ 315mm

2.application: water,gas,irrigation,drainage,construction

PE Pipe Butt Fusion Machine:

PE Pipe Welding Machine, But Fusion Welding Machine, Hot-melt Welding Machine, Hydraulic butt fusion welding machine. Hydraulic butt welding machine, HDPE butt fusion machine. Welding machine. Butt fusion Equipment

Application:

Suitable for welding of plastic pipes and fittings made of PE,PP,PVDF and can be operated in any complex working condition.

Features:

1. The machine body is equipped with four main clamps with the third clamp axially moved and adjusted.

2. Removable PTFE coated heating plate with separate temperature control system.

3. Electric milling cutter with reversible double cutting edge blades.

4. Hydraulic unit provides welding machine with compressing power.

5. Be made of lightweight and high strength material; simple structure and easy to operate.

6. Low starting pressure ensures reliable welding quality of small pipes.

7. Separate two-channel timer shows time in soaking and cooling phases.

8. High-accurate and shockproof pressure meter indicates clearer readings.

Model |

RDH315 | |

Pipe Size(mm) |

160,180,200,225,250,280,315 | |

Heating Plate Max.Temp |

270°C | |

Temp.Deviation In Surface |

less ±7°C | |

Pressure Adjustable Ranges |

0-6.3Mpa | |

Working Voltage |

220V,50Hz | |

Heating Plate Power |

3.1kw | |

Planning Tooler Power |

1.1kw | |

Hydraulic Unit Power |

0.75kw | |

Total Power |

4.95kw | |

Weight |

205kg(Net) | |

Packing

|

Cases |

Three Plywood Cases |

Volume |

1.115CBM | |

- Q:Which brand is the best for ultrasonic plastic welding machine?

- South Nekon Machinery Co., Ltd. is a large-scale ultrasonic equipment research and development, production and marketing enterprises, the company was founded in 1997, the division is specialized in producing all kinds of plastic welding standard 2600W-3200W plastic welding machine, plastic welding machine, plastic welding machine 4200W-5200W high-power welding equipment; 15K, 20K, 28K, 40K and other precision welding equipment, and all kinds of non-standard plastic welding equipment, plastic welding machine, plastic welding machine, four head six head plastic machine, hollow board glue box special welding machine, welding machine, guardrail tube, rotary hot plate welding machine, welding machine, automotive dashboard welding, automobile sunshade plate welding machine, welding machine, automobile lamp automobile bumper welding machine, and designed specifically for customers all kinds of non-standard automatic plastic welding equipment.

- Q:What's the difference between ultrasonic plastic welding machine and ultrasonic plastic hot melt machine?

- HelloBy ultrasonic Xiaobian for you to answer: the principle of ultrasonic plastic welding machine 20KHz is generated by the generator (or 15KHz) high voltage and high frequency signal, through changing systems, converts the signal into high frequency mechanical vibration on plastic workpieces,Through the surface of the workpiece and friction between molecules and the transfer to the interface temperature, when the temperature reaches the melting point of the workpiece itself, the interface is rapidly melting, and then fill in the gaps between the interface, when the motion stops, workpiece cooling under pressure at the same time, then achieve perfect welding.The hot melt machine adopts a pumping plate structure, and the heat of the heating plate is transferred to the welding surface of the upper and lower plastic heating parts by the electric heating method. The surface is melted, and the heating plate is rapidly exited, and the upper and the lower two heating elements are heated, and the fused surface is fused, solidified and integrated.Therefore, ultrasonic plastic welding machine through high-frequency mechanical vibration, friction heat generation plastic welding, and hot melt machine is heated by electric heating plastic softening welding

- Q:How many kinds of ultrasonic welding machine power are there?

- Is the power or frequency? Zhengzhou the Yellow River ultrasonic company has ultrasonic technology engineers, you ask him to ask, about the ultrasonic technology problems, he can answer you

- Q:Please describe in detail the 2015 mould material manufacturing process, pay attention to the problem, the relevant difficult solution

- You may often have this idea: the welding head design and production is very simple. Don't be misled, when using an improper processing or without tuning of the welding head, will give you the production to bring expensive losses -- it will damage the welding effect, even more serious damage will directly lead to the transducer or the generator. So the design of the welding head like it's not as simple as that, on the contrary will need a lot of professional knowledge and skills, how to ensure the welding head can be the most economical work? How to ensure the welding head can be mechanical vibration transducer conversion can be effectively delivered to the workpiece, forming stable welding in Nicle ultrasonic, our engineers will each link are considered very full. Even if has several years of experience in the design and development, we still believe that only through the strict test and quality control to produce the best welding head. Through the analysis of the application as a finite element (FEM) of this process, our engineers will be acoustic properties and mechanical properties of the welding head of the perfect combination, design the products in line with customer needs. Each set of welding head and mould our production, whether standard products or customized according to customer requirements, are all made of the best materials and after repeated test. Welding head shape, intensity and audio etc. various parameters after many tests, can accord with the most stringent standards, welding head and mould achieve the most perfect match. Material is one of the main reasons to ensure the effect of ultrasonic mold life on welding products, and the process of mold completion is complicated. Therefore, not only the mold engineer design must carefully select material, but also need to understand its own product requirements, the use of what kind of material, avoid negligence and affect its timeliness and quality.

- Q:Ultrasonic plastic welding machine power, the better the better?

- Different products for the power selection range, small pieces can be used in small power, with fragile also using small power to weld, such as 35K, for difficult to weld materials or pieces can be considered to welding with high power.

- Q:What are their differences? What are the manufacturers of high frequency welding machines?

- High frequency welding PVC

- Q:Must be able to believe 8700AD ultrasonic plastic welding machine often appear failures and treatment methods?

- BRANSON 8700 imported from the United States, as long as the maintenance of good, nothing

- Q:What kind of hot air plastic welding torch and plastic welding machine made in China? Used to weld plastic sheets and tubing

- Used a DSH-D type of hot air welding plastic guns, very good, especially suitable for welding plates, different nozzles can also be welded plastic cloth, seems to be 780 yuan, and spent two years, has not been a problem

- Q:What kind of factory will use big ultrasonic plastic welding machine?

- Instrument factory, bumper factory

- Q:How can ultrasonic plastic welding machine replace ultrasonic mould?

- First, the ultrasonic transducer horn contact the mold place, with cloth or alcohol wipe clean, followed by ultrasonic, mold a little to tighten!

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China (Mainland) |

| Year Established | 1993 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Butt Fusion Machine RDH315

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords