Ultra-thin slab copper mould plate used on continuous casting machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 200 pc/month

- Option:

- 1530

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Description

We can design and manufacture Ultra-thin slab copper mould plate used on continuous casting machine.

Size Length1530mm Width 1100mm , Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We are the leading professional designer and manufacturer for copper mould plates & tube.

The copper moulds supplied by CNBM adopt advanced European technology. Nowadays, CNBM is one of the largest copper moulds supplier and exporter with more than 30% market share in domestic market and 5% in the world market.

2.Main Features

Steady and high quality,

Packing : Strong, export worthy wooden cases. High quality products and excellent service.

Fast shipment; 30-40days for production;

Our products with world-class quality, competitive price, flexible payment terms, speedy delivery and excellent service.

We are supplying Size Length1530mm Width 1100mm , Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

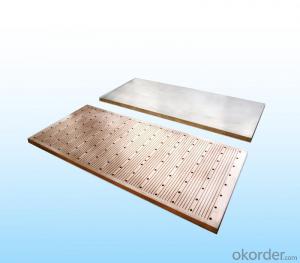

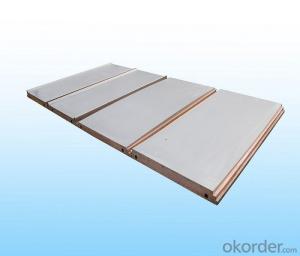

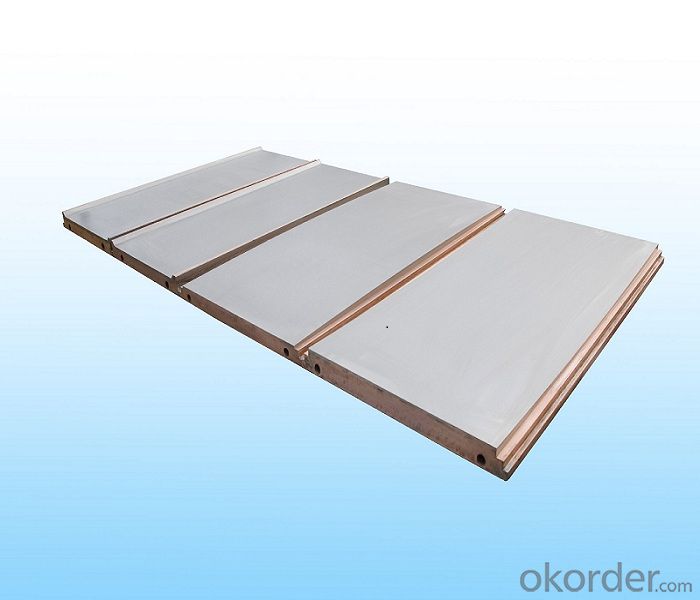

3. Images

4.Specification

Thin slab

We can design as per the customer’s specific requirements.

Length 1200-2000mm

Width 1100-1200 mm

Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We can design as per the customer’s specific requirements.

- Q:I made a 10 gallon boiler for distilling out of 16oz copper sheeting. I used copper rivets to hold the seams together, and lead free plumbing solder to seal the seams. I‘m thinking of getting a 60,000 BTU propane burner to heat it, but I am worried that it could melt the soldered seam at the base. Could this happen? Thanks

- If you have to ask, NO. If you were qualified to make a homemade boiler, you wouldn't have to ask.

- Q:What equipment can make the circuit board copper and aluminum.

- M51+M51-F low temperature aluminum copper, copper aluminum low temperature solution temperature of 179 degrees welding

- Q:how to make a solar bottle charger ?

- Use sheet metal shears to cut the copper flashing in a square or rectangle to fit the size of the electric burner. Be sure to use a piece of copper flashing that is thoroughly cleaned. You may use sandpaper to thoroughly remove any sign of corrosion before proceeding. 2 Place the copper flashing on the electric burner and turn the burner on. You will need to cook the flashing for as long as 30 minutes or more to develop a thick layer of black cupric oxide. 3 Allow the copper to cool slowly once the layer of cupric oxide has formed. It will begin to flake off and may do so with some force as the oxide and the copper cool at different rates. 4 Scrub the completely cooled copper under running water to remove any last remaining bits of oxide. Be gentle, as you do not want to remove any of the red cuprous oxide that has been created in heating the flashing. 5 Cut another piece of copper to the same size. Attach both panels using the alligator clips to the inside of the wide-mouth glass jar or plastic bottle with the top cut off. The panels should not touch and should bend to match the curves of the jar or bottle. 6 Connect the lead of the alligator clip which fastens the clean copper plate to the positive terminal of the meter. The negative terminal should then be connected to the cuprous oxide plate. 7 Make a solution of salt and water by dissolving the salt in hot tap water. You should make enough solution to barely cover the bottom of the plates, leaving the clips high and dry. 8 Place your solar panel in the sun to see the gauge jump to reflect the current your project has created.

- Q:The chemical composition of yellow copper plate

- Purity measurementThe purity of brass can be measured by Archimedes principle, the volume and quality of the sample are measured, and the proportion of copper in brass is calculated according to the density of copper and the density of zinc.

- Q:How many grams of copper paper do the cards do?

- Printed paper with 300g copper plates!

- Q:AQA Sheet- Any help appreciated :DBonnie and clyde were asked to find out the percentage composition of brass. they were told that zinc dissolved in hydrochloric acid to give a solution of zinc chloride and hydrogen gas.Copper does not react with hydrochloric acid.They carried out the following procedure but steps 3 5 and 6 are missing complete the steps1-they weighed out 10g of brass shavings.2-they added the shavings to some hydrochloric acid. they stirred the mixture and waited until the reaction was finished.3- …4-they collected the solid and washed it with lots of dissolved water.5-…6-…Also answer the following questions:1 why did they use brass shavings and not a brass block?2 in step 2 how could they tell the reaction was finished?3a if the mass of copper was found to be 6.5g what was the mass of zinc?3b what was the percentage composition of the brass?thanks

- You have to drill holes, using a masonry bit, thru the tile, and use an anchor of some sort. Best would be some sort of toggle bolt thru the drywall itself. A plastic expansion anchor would suffice. Any force on the tile itself, may cause eventual breakage.

- Q:The rod fits into a circular hole in a copper sheet with a clearance of 0.017 mm completely around it when both it and the sheet are at 18°C. (a) At what temperature will the clearance be zero? (b) Would such a tight fit be possible if the sheet were brass and the rod were copper?Explain. Also, can you please show your work.

- Using A A0*(1 + 2*α*ΔT) we need ΔT where the area of each is the same so [A0*(1 + 2*α*ΔT)] brass [A0*(1 + 2*α*ΔT)] copper to simplify A π*r^2 so we can eliminate π from both sides leaving r^2 [0.70x10^-2m)^2*(1 + 2*2.0x10^-5*ΔT) (0.70x10^-2 + 0.017x10^-3)^2*(1 + 2*1.7x10^-5)*ΔT) Simplifying 4.9x10^-5 + 1.96x10^-9*ΔT 4.924x10^-5 + 1.674x10^-9ΔT So ΔT (4.924x10^-5 - 4.9x10^-5)/(1.96x10^-9 - 1.674x10^-9) 833oC So Tf 833 - 18 815oC b) If the metals were reversed then there could not be a tight fit because the brass plate would expand more rapidly that the copper rod so the clearance would become larger not smaller

- Q:What are pennies made out of?

- Copper plating and zinc

- Q:Copper sheet acquired a green color over the yearsThe page is white Platinum does not react with oxygen at room temperaturegallium metal melts in your hands

- Bartender, I'll have what he's drinking

- Q:5 facts of each!!!

- Denver Omelot. Also known as the Western Omelot. It usually has diced ham, onions, and green bell peppers. It may also have some cheese, and is usually served with hash brown potatoes on the side.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ultra-thin slab copper mould plate used on continuous casting machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 200 pc/month

- Option:

- 1530

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords