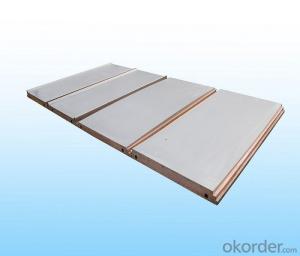

Copper Sheet CDA 10200-11000

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Application: | Thickness: | Shape: | |||

| Width: | Grade: | Alloy Or Not: | |||

| Min trial order: | Type: | Product name: |

Packaging & Delivery

| Packaging Detail: | Standard export packing Copper Sheet (CDA 10200,11000) or following customers demand |

| Delivery Detail: | within a month |

Specifications

As an international manufacturer, supplier for copper sheet, Shanghai Building Material Corporation produces slitting, edging, and oscillate winding to fit your specific copper requirements. Check back here often for copper sheet.

We are capable of producing a wide variety of precision strip products to special requirements, and is geared to handle high volumes with tight tolerances. Continuous strip-casting machines produce long, weld-free coils of uniform composition and properties, and automatic electronic gauge-controls maintain consistent thickness.

Copper sheet and brass sheet Production capacity

About 5000ton per month

Copper foil and brass foil: the thickness from 0.008mm to 0.15mm, all available.

Copper and brass strip: the thickness from 0.15mm to 6.0mm, all available

For copper sheet and strip: Min trial order 1 ton each thickness. (only for the thickness: 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.1mm, 1.2mm, 1.2mm. for other thickness, the trial order will be 4tons of each thickness)

Min normal order: 4tons each thickness

For copper foil (copper tape):

Min trial order 100kg each thickness. (normal thickness: 0.02mm, 0.025mm, 0.03mm, 0.04mm, 0.05mm, 0.06mm, 0.07mm, 0.08mm, 0.09mm, 0.10mm, 0.12mm, 0.15mm).

Min normal order: 300kgs each thickness

Applications for copper strip, copper sheet, brass Strip and sheet

Copper strip and copper sheet for Transformer

Copper strip and copper sheet for Water Heater exchanger unit

Copper strip and copper sheet for Automotive manufacturers Brass strip and brass sheet for Electrical equipment manufacturers

Copper strip and brass strip and bronze strip for Mints (for coinage)

Product Ranges of copper sheet, copper strip and brass strip

Standard Range of Coppers and Cooper Alloys Manufactured | |

Copper | CDA 10200,11000 and Best Sales Item |

Radiator Copper | CDA 14000 series |

Leadframe | CDA 19210 new and best |

Plain Brasses | CDA 20000 series |

Phosphor Bronzes | C51000,C51010,C51110,C52100 and C52400 |

Nickel Silvers | CDA 73000 to 77000 |

Available Thickness and Width Ranges | |||||||

Thickness Range | Width Range | ||||||

inch | mm | inch | mm | ||||

0.0013 | 0.0040 | 0.035 | 0.100 | 0.5 | 13 | 12.5 | 325 |

0.0040 | 0.0200 | 0.100 | 0.500 | 0.5 | 24 | 12.5 | 610 |

0.0200 | 0.0320 | 0.500 | 0.800 | 0.5 | 24 | 12.5 | 610 |

0.0320 | 0.0700 | 0.800 | 1.800 | 0.5 | 24 | 12.5 | 610 |

0.0700 | 0.1000 | 1.800 | 2.500 | 1 | 24 | 25 | 610 |

- Q:Hello, I need to cover the hulls of a 24 m catamaran with copper foil or plate. I am wondering if someone can help with this rare technique: everyone uses chemical anti fouling these days and it seems that the old and best technique has disappeared.

- they used to nail it to the wooden hull. That wont work. I have also pondered doing this.But pondering is as far as I got. Why dont you just do a small section and see what happens.

- Q:I would like to get into metal molding, but I have some Questions.1. What would be a material that could hold up to molten metal?2. What would some good melting metals be? I can get sheet metal whenever I want, but I don't know if the melting point is low enough.3. What would I need to melt the metal? I would prefer if the metals could be melted simply on the stove, or at least in a fire.4. Would I be able to change a metal's actual color, or would I need seperate metals for each color?

- lead, tin and pewter have some of the lowest melting points, but when molten are still hot and viscous enough to cause serious injuries. You can cast into many things from plaster of paris, the carved insides of cuttlefish to into damp clay earth, but all are pretty risky if you dont fully understand the procedures, techniques and safety. Any damp or air in your mould can cause the mould to blow - literally explode - showering yourself and everything around you in molten metal, so i absolutely suggest that you find some local classes or even an apprenticeship if you wish to get into this! A great new alternative around recently is PMC or Precious Metal Clay, which as it says is a clay substance formed of various kaolin's etc with silver or gold. These you form items as you would from any clay, before heating with a blowtorch or similar to burn off the clay, leaving behind hallmark quality silver or gold. With the PMC you can get as much detail, or even more then with casting although it is pricey due to the precious metal content, but a great alternative when you are limited for facilities, and much more manageable to use without a foundry! :-)

- Q:What do you mean by "S1-100" on the wiring board?

- S4 includes starting duty cycle: according to a series of work in the same period, each cycle comprises a section on temperature has significant effect on the starting time, a constant load running time and a stopping.

- Q:How to remove the copper patina, ask God for us

- Use pharmacies have sold for the treatment of athlete's foot medicine, "foot light scattered" on it.

- Q:I‘m seeking advice from someone acquainted with the types of plastics that corrode coins. I know there is a specific type of damage that can be done to coins (PVC corrosion?) and I want to know what types, if any, can corrode or damage coins.

- Plastic does not corrode coins. Coin holders known as flips can contain PVC. These can cause a green haze on a coin which is very difficult to remove. Corrosion is caused by environmental gasses, and if a coin is buried. When early American copper coins were struck, the copper that was used was already corroded. This was due to copper sheets being kept at the bottom of ships bringing the copper from europe. The exposure to salt water corroded many of the copper sheets. This is why many early US copper coins are difficult to find without corrosion. With modern coins, you should not have any problems concerning corrosion.

- Q:2.00 X 10^5 lbs of copper sheets eqauls how many atoms of copper?

- depending on what kind of car you have you might need a new wiper transmissionthe pop you heard could be a knuckle that popped off on the wiper transyou should always make sure your wipers are free before turning them onor leaving your parking spot.this could be an expensive lesson

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Copper Sheet CDA 10200-11000

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products