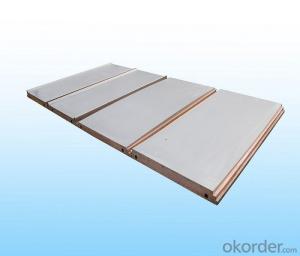

Rectangle copper mould plate used on continuous casting machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

- Option:

- 700-900

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Description

Rectangle copper mould plate Size range Length700-900 Width 200-300mm ,Thickness 30-70mm, Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We are the leading professional designer and manufacturer for copper mould plates & tube.

We supply Copper Moulds of Highest Quality, ensuring Maximum Life, excellent Heat Resistivity and smoothest Casting Operational efficiency.

The copper moulds supplied by CNBM adopt advanced European technology. Nowadays, CNBM is one of the largest copper moulds supplier and exporter with more than 30% market share in domestic market and 5% in the world market.

2.Main Features

We commit to supply products with world-class quality, competitive price, flexible payment terms, speedy delivery and excellent service, and we can also give technical guidance to help our customers to reduce the cost and increase the productivity. We have got high reputation from various customers all over the world.

We are supplying High Slab copper mould plate with Size range Length700-900 Width 200-300mm ,Thickness 30-70mm, Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

Steady and high quality,

We can design as per the customer’s specific requirements. Fast shipment; 30-40days for production;

Packing : Strong, export worthy wooden cases.

3. Images

4.Specification

Rectangle

Length 700-900mm

Width 200-300 mm

Thickness 30-70mm

Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We can design as per the customer’s specific requirements.

- Q:Copper sets, copper and other copper parts, where the amount of more?

- According to the use conditions according to a certain proportion in the work surface processing hole and fill in the solid lubricant, copper alloy high strength provides high bearing capacity and solid lubricant can form low friction. Under dry friction conditions, we design a pre - formed synovial membrane on the surface of the bearing to ensure that the solid lubricant is transferred to the dual parts in the shortest possible time, and an effective solid lubricant film is formed

- Q:or 1800‘s not sure.

- From photography and DSLR camera basics right through to advanced techniques used by the professionals, this course will quickly and easily get your photography skills focused! Go here tr.im/rlFgD By the end of this course you will have developed an instinctive skill-for-life that will enable you to capture truly stunning photos that not only amaze your friends and family. but could also open the doors to a brand new career.

- Q:I‘ve handed in my sheet with all of my working on it so I can‘t refer to it to work these questions out :/ The questions areCalculate the length of a copper wire of cross sectional area 0.8x10^-7 m^2 that has a resistance of 2 ohmsCalculate the resistance between the large faces of a slab of germanium of thickness 1mm and area 1.5cm^2Would someone be able to tell me how to work it out? I‘d really appreciate it :]Thanks

- R r x L/A where R resistance, r resistivity, A area of xsection and L length A is given, R is given but r is missing so you cannot find R. Sorry.

- Q:Is coated paper hard? What kind of coated paper can be waterproof?

- If it's fake, it won't work, so that's one of the biggest differences between real money and fake money

- Q:What's the safer way to do this than to iron the copper plate? It's said to be poisonous

- As an amateur of electronic technology, the printed circuit boards were manufactured in this way many years ago.

- Q:I heard something about plastic and aluminum foil and rolling it up.Can someone tell me how to do this or your way.ALSO if it was to be rolled up would it be long? or do i fold it a couple time then roll it up so its not long? IDK what im doing, the teacher gave us 2 wires and told us to make a capacitor lol

- I cannot tell exactly without knowing the running condition of the preasent set-up. Yet you can be rest assured that if you change them for the better, you,no doubt, will enjoy more relaxing power while driving.

- Q:Wind mill, light bulb, fan and throwing of ball is already taken :(We cannot make repeated models, therefore, I want easy to models which are easy to make. If you can help more, please tell me how I can make the model too. Only if you can. Thank you :)

- Negative is my answer, one thing has nothing to do with the other period.

- Q:I was doing a chem lab experiment. And our teacher kinda didn‘t mention the fact that there‘d be a yellow toxic cloud coming out. I was a lil‘ to close and kinda inhaled it. I asked him about it he said not to breath it in, and I didn‘t tell him that kinda already had. I‘ve had a killer headache since, and have felt sick. Is it just a coincidence, and what should I do if it‘s from the chemicals?

- The gas was nitrogen dioxide which is pretty horrible obnoxious stuff If you only got a little whiff then it shouldn't do you any lasting harm but if you are worried talk to a doctor. from material data sheet for NO2 INHALATION EFFECTS: Vapors are a strong irritant to the pulmonary tract. Initial symptoms of inhalation may be moderate and include irritation of the eyes and throat, tightness of the chest, headache, nausea and gradual loss of strength. Severe symptoms may be delayed (possibly for 5 to 7 hours) and include cyanosis, increased difficulty in breathing, irregular respiration, lassitude and possible eventual death due to pulmonary edema in untreated cases. Your teacher sounds like he doesn't know what he's doing. This should have been done in a fume cupboard.

- Q:How do rubber and copper react and turn green?

- At present, it is better for the front wall mirror special glue. Sell on the net, won't corrode copper.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rectangle copper mould plate used on continuous casting machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

- Option:

- 700-900

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords