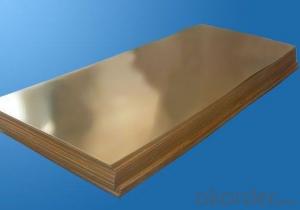

High quality-copper sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

pecifications

Copper sheet

1.Model: C11000 T1 T2 T3 T4

2.Thickness: 0.05MM to 2.00MM

3.Width: Ranges from 10MM to 450MM,

Copper Plate

Our Products are widely used in lead frame material, solar photovoltaic ribbon, transformers, radio frequency cables, copper clad alaluminum, heat exchangers, electronic stamping and other industries

Model: C1100, T2, TP2, TU2, and other kinds of grades

Thickness: Range from 0.05MM to 2.00MM

Width: Ranges from 10MM to 450MM,

Piece weight: 5000kg max

Industry species:

1, Radio-frequency cable: The length can reach 6000meters in 0.2mm thickness

2, Transformer: Patented trimming, ensure the edge in right angle

3, Photovoltaic copper belt: 100%conductivity, 45 hv

4, Copper cladding aluminum: Applied in wire

5, Electronics: Clean surface, steady tolerance, neat ribbon, used for electroplating and high speed punch

6, Heat exchanger: Applied in nuclear power plant and submarine industry

- Q:what is copper sheet,is it available in shops and how much would it cost,its expensive

- It's copper in the form of a thin (or thick) sheet. Yes, you can buy it. cost varies a lot, depending on thickness, size, and other factors. reference has examples. .

- Q:what is the place were people purchase metal?

- Metal dealer. Look in your local yellow pages under metals. Also look under the metal you want, like steel, aluminum, copper, etc. You can also look under sheet metal or pipe. You should find what you want.

- Q:Anyone know where there is brass or copper that is sold in sheets at affordable prices?

- Fireworks stands are illegal in Houston. However, as soon as you cross external the town limits, the stands can without difficulty be located. You're going to get ticketed for bringing them back into town in case you are caught. Most of the time they've officers gazing the stands and can discontinue you for those who return into town limits. At the least they've prior to now.

- Q:my son was replacing the shower spicket in the bathroom and he couldn‘t get it twisted off the copper pipe and twisted too hard and split the copper pipe for the bathtub so when you pull the knob to use the shower it spews water inside the wall where the split is. there is no access panel to get to the plumbing so i was thinking of unsweating the joint and replacing the the piece of copper tube. is this possible or should i cut a hole and go in from the other side. its all copper tubing and fittings

- I can't imagine you'll be able to get to it w/o opening the wall. Hopefully it's just sheet-rock on the other side, and easy to patch paint.

- Q:How to distinguish between paper? Such as paper, light weight coated paper, light weight coated paper, matt coated paper and matte powder etc.

- Weight: 45, 50, 60, 70, 80 (g/m2). 3. light weight coated paper is light weight coated paper referred to, it was also known as the LWC, its name is English LWC paper (Light Weight Coated Paper) is an international, in the area of Taiwan called it illustrated paper or light weight coated paper.

- Q:A. A hot dog is cooked. (chemical?)B. Salad dressing is mixed with mayo. (physical?)C. Water is boiled. (physical?)D. Old ham goes bad in the fridge (chemical?)E. A rock star gets a tattoo on his head (chemical?)F. Gallium melts in your hand (chemical?)G. This page is white (???)H, The copper sheets that form the skin of the statue of liberty have turned green over the years (physical?)Could someone please tell me whether i‘m correct or not, and help me on G? Thanks in advance.

- No offense meant to any who answer, in the affirmative, but Tile is essentially glass, and other than some absorbtion by the grout, Tile (glazed) is completely NON porous. You will get answers that state YES, and links to various paint formulations, but I offer a suggestion. I tile and paint, every day of my life, NEVER together in the same sense. Take a piece of scrap tile, spend all the $$$ you wish on any Miracle, and put it on a floor, when dry, then walk on it for a time frame. Beyond the truth that some paints are designed for environmental conditions, Garage floor traffic, a Floor in a house suffers the same or more abuse than any other surface. Consider taime and $$ spent on having your nails done, only to get home, prepare a meal and scratch a nail. I suspect you'll be dissatisfied. Steven Wolf just my 2 sense Unless you're willing to remove the tile, find a piece of room size carpet to lay over.

- Q:How we can store the solar energy in to a non traditional way ?

- Whats wrong with the traditional ways? Like heating black water barrels or concrete for times when it is dark? Or do you mean electricity? There was a power plant in Arkansas in the late '80's that was compressing air in a huge underground chamber during the day to power a turbine during dark hours.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High quality-copper sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products