High Purity Heat-Resistant Ceramic Fiber Paper

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High purity heat-resistant ceramic fiber paper STD

The general information of ceramic fiber paper

Paperis CMAX ceramic fiber made from high quality she clay, high purity alumina and silica oxide by rotating or blowing process. Asbestos is free. Double needle provide Paperwith great tensile or strength, ease of installation.

Products have been classified as a sexually transmitted disease, HP, ha, and hz, respectively corresponding to different maximum operating temperature 1000 ℃, 1100 ℃, 1200 ℃ and 1350 ℃

The properties of the ceramic fiber paper

Heat resistance

Light weight

Low coefficient of thermal conductivity

Low heat storage

To adapt to the thermal shock

High tensile strength

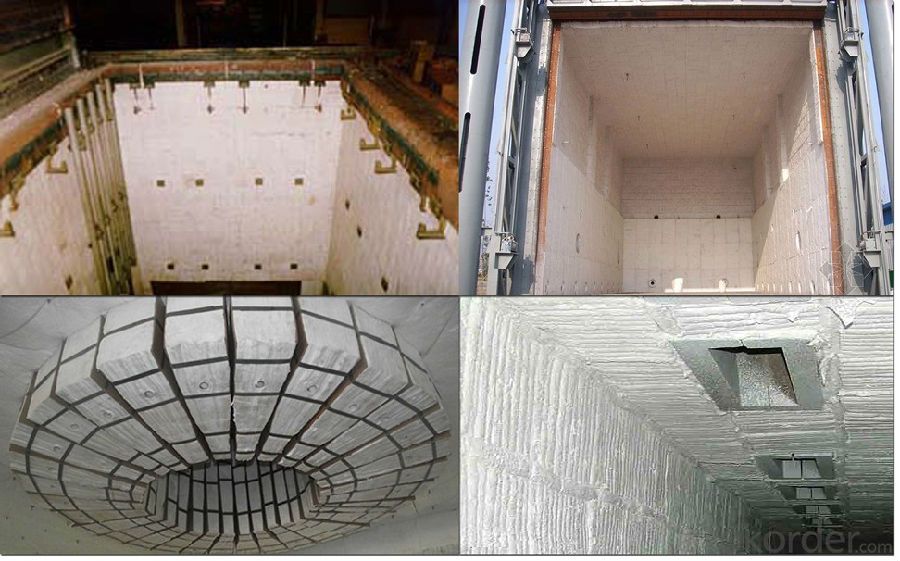

The application of ceramic fiber paper

Petrochemical process heating refractory fiber lining

Heat treatment furnace or intermittent kiln lining (shuttle) hot face

General backup furnace insulation

Heat sealing kiln car or oven door

Electrical insulators

Pictures of ceramic fiber paper

FAQ

1. What are your products?

We have all kinds of refractory brick, slurry, mortar, cement, ceramic fiber products, etc.

Or you can browse our product to choose what you need.

2. How to control the quality of the product?

Have a strict quality control system in the process of material selection and production, our refractory material and ceramic fiber effective control of product quality to meet customer demand.

From the selection of raw materials, our quality control. The quality of the raw material certificate is required, each batch will be tested before use. In the process of production, quality control is made up of workers, then each classification, quality supervision and inspection.

3. Can you give me a brief introduction of the application of your products?

We mainly specialized in refractory steel, cement, glass, ceramics, oil chemical, electric power industry, etc.

4. If I need your quotation, what information do you need?

In order to choose the right product, will be appreciated

- Q:How to paste the ceramic fiber paper on the iron plate?

- Stick on the plate for what you see over the place, or if used in high temperature place, we recommend a special high temperature fireproof glue;

- Q:Why is there no direct relationship between thermal conductivity and conductivity of ceramics?

- Ceramic fiber paper is made from high purity refractory fiber and used in high temperature insulation.

- Q:What fiber glass made of ceramic fiber paper?

- Ceramic fiber paper production process is:Beat out - pulp - pulp - long mesh forming - vacuum dehydration - drying - cutting - winding - packaging

- Q:What are the prospects for ceramic fiber paper and how much investment will be needed?.

- In recent years, due to the global energy prices continue to rise, energy saving has become a China national strategy background, than the insulation bricks and other traditional refractory pouring material such as 10-30% ceramic fiber has been used more widely in the domestic more Chinese, development prospects are very promising.

- Q:Is everybody ceramic fiber cotton poisonous?

- Depends on the production process is the above kind, the province may not, but the production process may have some problems.

- Q:What are the materials for making ceramic fibers?

- The main raw material for the production of ceramic fiber cotton is mainly three two aluminum oxide, and silicon dioxide production process through the silk process, Wuhan, Kyrgyzstan rnd-digital ceramic fiber and ceramic foam with instructions on

- Q:What are the features of ceramic fiber gaskets?

- 1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

- Q:Expert answer. What is the difference between ceramic fiber paper and ceramic fiber cloth?

- Ceramic fiber paper is made from high purity ceramic fiber and a small amount of binding agents which are scientifically selected and tightly controlled. The wet vacuum forming process makes the fiber distribution very uniform, and the thickness and volume density of the aluminosilicate fiber paper can be strictly controlled. The binder will be completely ablated during use.

- Q:Ceramic fiber spray and thrown silk floss, which is better?

- 1, fiber diameter: rejection fiber more coarse, rejection filament fiber is generally 3.0-5.0 mu m, spinneret fiber is generally 2.0-3.0 mu m;2, the length of fiber yarn: rejection fiber longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;3, the coefficient of thermal conductivity: spray cotton fiber is lower than that of the thrown silk;4, the tensile and flexural strength: thrown silk because fiber thicker than that of spraying cotton;

- Q:The condition of ceramic glass fiber at high temperature

- Generally, glass fibers can be pulled long and cut short when required. However, ceramics are difficult to control and difficult to grow because of technological conditions;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Purity Heat-Resistant Ceramic Fiber Paper

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords