Rock Wool, Rock Wool Board Insulation Price,Rock Wool Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Board

Rockwool felt is produced from molten basalt rocks, spun to fine fibers, slightly bonded with binder formed into flexible rolls. It is also produced by stitching rock fibers with cotton or fiberglass yarns.It can be non-faced or faced with wire mesh.

Rockwool blanket uses high-quality basalt as raw material whose melting point is above 1000 ºC and has good effects on heat insulation and sound absorption.

It has good properties of fire resistance, pest proof, corrosion resistance, stable chemical property and do not contain asbestos. It is green environmental production and do no harm to human bodies

Product Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3. Rock wool blanket will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Product Advantages:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Main Product Features:

Excellent performance

Fire-Proof

Good thermal Insulation

Soundproofing

Water-repellent

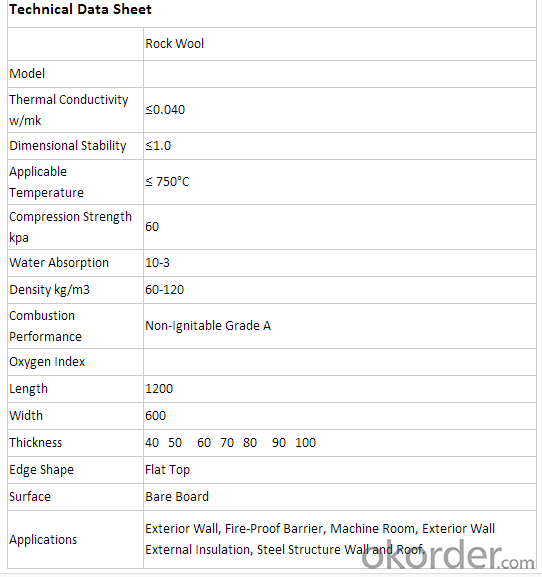

Product Specifications:

FAQ:

1.Q:What is your delivery time?

A : within 10-15 days after receive your prepayment,and we can also deliver as per your requirment.

2.Q:Which payment can you accept?

A: TT or LC.

3.Q:What is your MOQ?

A: 40'HQ container, that's about 65 cubic meters.

4.Q: I am interested in the products but I don't have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order.

Product Picture

- Q:What are the exterior wall thermal insulation materials?

- Organic thermal insulation material:Such as rice straw, rice husk, sugarcane fiber, softwood, kapok, sawdust, wood shavings, wood fiber and their products.Advantages: this kind of material has a small volume, a wide range of sources, most of the low price, but the moisture absorption is large, easy to decay after damp, and easy to decompose or burn at high temperature.

- Q:How can the exhaust pipe of a gas water heater be insulated by going through the glass?

- Therefore, the temperature of the inner pipe of the water heater is higher, but the outer pipe is not very high because the outdoor air is flowing.At the same time, the air is a poor heat conductor, so the actual temperature of the outer surface of the outer tube of the water heater is not very high. That is to say, no special heat insulation measures are needed when the exhaust pipe of the gas water heater passes through the glass.

- Q:What's the difference between glass fiber and mineral wool?

- Melting natural rock or metallurgical slag in a cupola or a pool furnace, etc. by blowing or centrifuging.

- Q:What is the best sound proof cotton in the decorative plaster board partition wall? Mineral wool rock and glass wool.

- Rock wool and glass wool on the overall performance of almost the same, are brittle fiber composition, you need to get a good sound insulation, you need to use high-density materials, usually 80KG per cubic meter of the use of more. The price range is 40-60 yuan per square meter. This material can cause skin allergies and dust can cause respiratory allergies. Therefore, construction should pay attention to the construction personnel physical protection, materials must be completely sealed to the wall inside. If it is a ceiling with holes, you must not use glass wool.

- Q:What is the difference between high-density rock wool board and hard rock wool board?

- But the quality of rock wool is very different, and the heat preservation property is low, the tensile strength is low, and the durability is poor. Glass wool and rock wool in the performance of many similarities, but it feels better than rock wool, can improve the working conditions of workers. But it is higher in price than rock wool.

- Q:Rock wool, EIA inorganic insulation mortar, polystyrene particles, polystyrene foam board advantages and disadvantages comparison?

- Rock wool (mineral wool): it is a kind of inorganic green product from natural mineral, non-toxic and harmless. The utility model has the advantages of good fireproof performance and good durability, and can be synchronized with the structure life, and the price is low. When the insulation performance is satisfied, the utility model can also have a sound insulation effect, and the fire prevention grade is level a. But the quality of rock wool is very different, and the heat preservation performance is good, the density is low, the tensile strength is low, and the durability is poor, and the paint can not be used directly.

- Q:What are the differences between slag wool and rock wool?

- Rock wool and slag wool, chemical composition and acidity coefficient comparison in our country, the main raw material for blast furnace slag slag cotton general or other metallurgical slag, the main raw material for rock wool basalt or diabase, the chemical composition of the differences between them are larger (

- Q:What are the requirements for floor and exterior wall waterproofing in building construction?

- The joining of different structural materials shall be made of salt resistant fiberglass mesh or hot galvanized galvanized wire mesh of not less than 150mm on each side for anti cracking strengthening treatment

- Q:Which is better, roofing rock wool or glass wool?

- Rock wool: also known as asbestos, is a kind of mineral cotton. A fluffy short staple fiber made from natural rock and minerals. Rock wool is a kind of inorganic fiber made of natural rock, such as Xuan Wuyan, gabbro, dolomite, iron ore, bauxite and so on. It is made by melting and fibrosis at high temperature. Rock wool, used for ablation resistant, high temperature resistant insulating material; sound-absorbing material, insulation building materials and equipment; and natural asbestos substitute for cement products, rubber reinforcing materials and high temperature sealing material, high temperature filter material and high temperature catalyst carrier etc.. 1., insulation performance: good insulation performance, rock wool, slag cotton products basic characteristics. 2., combustion performance 3., sound insulation performance: rock wool, slag cotton products, with excellent sound insulation and sound absorption performance.

- Q:What are the building energy saving materials?

- At present, China's common energy-saving insulation materials are mainly rock wool, glass wool, polystyrene foam, cement, polystyrene board, silicate composite insulation mortar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rock Wool, Rock Wool Board Insulation Price,Rock Wool Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords