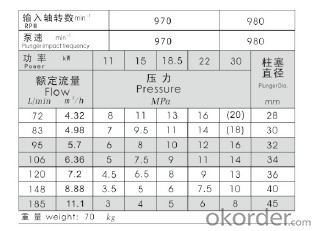

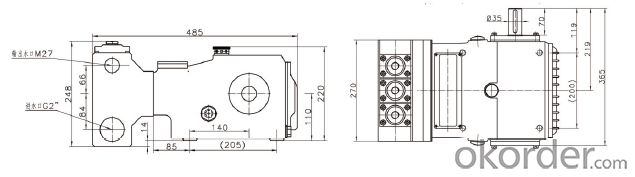

3D5-S Type Large Flow High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

It is our updated product with the characteristics of small body, samll weight, and the small power for the large flow. The power is only 11-30kw, but the flow can reach 185L/min. It can be equipped with diesel, water tank, high-pressure rubber hose(100m), low pressure water tube, spraying gun, roll, dhassis, wheel and drawing rod forming a washing system, the pushing force of whihc can reach 210N. It is applied for the water cleaning of the pipes at the narrow space such as restaurant, hotel, residential building, municipal sanitation, workshops and so on. The cleaned pipes may be 700mm of diameter and 100mm of length. It is not only for transmission of clear water and emulsification liquid, but also for the transmission of the chemical liquid.

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q:Can an air pump be used for inflatable mattresses or camping gear?

- Indeed, inflatable mattresses or camping gear can certainly be inflated using an air pump. In reality, employing an air pump proves to be the utmost efficient and convenient means of inflating such items. It not only saves time and effort but also surpasses the laborious task of manually blowing air into the mattress or gear. Moreover, numerous air pumps are equipped with diverse nozzle attachments that cater to various valve sizes, rendering them compatible with an array of inflatable items. Thus, whether one embarks on a camping excursion or seeks to inflate an air mattress within the comfort of their home, an air pump undeniably emerges as an invaluable tool.

- Q:Pneumatic tools are used to air pressure, and piston type compressors can generally provide the rated exhaust pressure between 7 kg to 8 kg, the amount of exhaust per minute of knowledge change, then this is how to calculate?

- 1, determine your gas consumption (pneumatic tools can be used to obtain), gas pressure. 8 kilograms is enough2 and then select the right air compressor according to the amount of air you have calculated. Generally more than 20% of the rated gas (consider leakage, etc., of course, the choice is just right, you use those gas equipment will not use it at the same time.)3, the pressure should be slightly larger choice, because the gas pressure loss in accordance with the transmission distance4, of course, willing to spend money, with much better frequency conversion screw machine point, it can be based on your actual consumption (to change the frequency to change the motor speed, power), better scalability (if you want to have more gas, will no longer increase equipment... At most, the frequency converter is used as the power frequency machine, and the electricity saved at that time saved the converter's cost. There are some tips for choosing the main road. When you buy the equipment, you can ask the manufacturer to help you design itPiston compressor is not what you said, the rated pressure is only 7---8 kg, and its pressure range is wider than the screw machine, 200 kilograms also have!!! Screw machine, then the first level of compression will be 13-15 kilograms, two compressed 30 kg.....If the screw machine, the wearing parts are less than the piston machine.... Like the piston, often replace the piston ring, into the exhaust valve, etc., and these have special maintenance personnel to engage in trouble

- Q:Can an air pump be used for inflating tires with different valve types?

- Indeed, an air pump is capable of inflating tires equipped with varying valve types. Numerous air pumps are accompanied by adapters or attachments enabling their compatibility with different valve types, including Schrader valves (commonly found on car tires) and Presta valves (typically found on bicycle tires). By conveniently interchanging these adapters or attachments based on the valve type, the air pump becomes versatile in its ability to inflate tires with different valve types.

- Q:Are air pumps suitable for inflating air loungers for indoor use?

- Yes, air pumps are suitable for inflating air loungers for indoor use. Air loungers are designed to be easily inflated and deflated, and an air pump provides a quick and efficient way to inflate them. Using an air pump ensures that the air lounger is properly inflated to provide the desired comfort and support. Additionally, air pumps often come with various nozzle attachments that can fit different types of valves, making them suitable for inflating different types of air loungers. Overall, using an air pump is a convenient and effective method for inflating air loungers for indoor use.

- Q:Can an air pump be used for inflatable theater props?

- Certainly! An air pump has the capability to inflate inflatable theater props. In order for large balloons or characters used as inflatable theater props to achieve proper inflation, they typically need to be filled with air. An air pump is specifically engineered to deliver a continuous flow of air, making it a perfect instrument for inflating theater props. It is crucial to select an appropriate air pump that matches the particular prop, as some may necessitate higher power or special valve fittings. Moreover, employing an air pump guarantees a rapid and effective inflation procedure, enabling theater productions to conveniently assemble and disassemble their props as required.

- Q:How does an air pump handle voltage fluctuations?

- The smooth operation of an air pump is ensured by equipping it with various mechanisms that handle voltage fluctuations. The motor controller, which acts as a bridge between the power supply and the motor, is the primary component responsible for regulating these fluctuations. When voltage fluctuations occur, the motor controller detects them and adjusts the power supplied to the motor accordingly. It has the ability to increase or decrease the voltage in order to maintain a stable speed and prevent the motor from overheating or getting damaged. This regulation is incredibly important because excessive voltage can cause the motor to be overloaded and burnt out, while low voltage can result in insufficient power to effectively operate the pump. In addition to the motor controller, many air pumps also have voltage stabilizers or surge protectors incorporated into them. These devices are specifically designed to minimize the impact of sudden spikes or drops in voltage. A voltage stabilizer ensures a constant voltage output, compensating for fluctuations and keeping the air pump running smoothly. On the other hand, surge protectors are responsible for safeguarding the pump from abrupt surges or spikes in voltage, thus preventing damage to its internal components. To sum up, an air pump effectively manages voltage fluctuations by utilizing its motor controller to adjust the power supplied to the motor for stable operation. Furthermore, voltage stabilizers and surge protectors are often included to mitigate the effects of sudden voltage changes and protect the pump from potential harm.

- Q:Can an air pump be used for inflatable water obstacles?

- Yes, an air pump can be used for inflatable water obstacles. It is commonly used to inflate and maintain the buoyancy of such obstacles, ensuring they are properly inflated and able to support weight and withstand water conditions.

- Q:What is the maximum number of air pumps that can be connected in series?

- The number of air pumps that can be connected in series is determined by several factors, including the power supply, voltage ratings, and individual pump capacity. To find the maximum number of pumps that can be connected in series, it is important to consider the total power consumption and pump compatibility. Firstly, it is necessary to check the power supply specifications. If the power supply can handle the combined power consumption of multiple pumps, it becomes possible to connect them in series. Additionally, it is important to ensure that all pumps have matching or acceptable voltage ratings. Connecting pumps with different voltage requirements can cause damage or malfunction. Furthermore, it is important to consider the capacity of each pump and the required airflow. Connecting too many pumps in series can result in decreased airflow due to increased resistance. Therefore, it is crucial to assess the desired airflow and match it with the combined capacity of the pumps. Ultimately, it is recommended to consult the manufacturer's guidelines or seek professional advice to determine the maximum number of air pumps that can be connected in series.

- Q:Can an air pump be used for inflating air hockey tables?

- Indeed, an air pump has the capability to inflate air hockey tables. To maintain the necessary cushion of air that enables the puck to glide effortlessly across the surface, air hockey tables typically necessitate a continuous flow of air. Inflating the table and supplying the essential air flow can be accomplished using an air pump, which may be either manual or electric. However, it is crucial to verify that the air pump possesses a suitable nozzle or attachment to fit the valve on the air hockey table. Furthermore, to ensure optimal performance, it is advised to adhere to the manufacturer's instructions for both inflating and maintaining the air pressure in the table.

- Q:How does an air pump handle different pressure measurement units?

- An air pump typically handles different pressure measurement units by providing various options for selecting the desired unit of measurement. This can be done by using a pressure unit selector or a digital display that allows users to switch between units such as psi (pounds per square inch), bar, kPa (kilopascal), or mmHg (millimeters of mercury). By offering these options, the air pump ensures compatibility with different pressure measurement systems and allows users to easily switch between units as needed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3D5-S Type Large Flow High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products