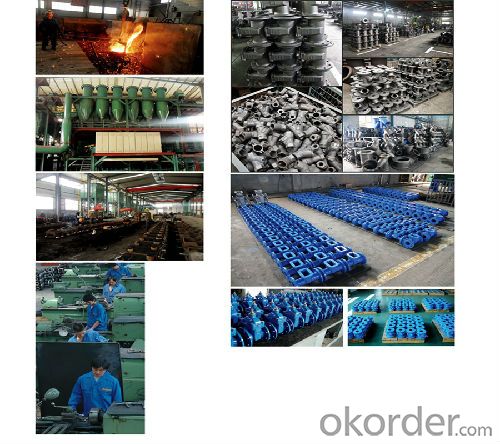

CHECK VALVE SWING DUCTILE IRON/ WCB DN40- DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | High Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | High Temperature |

Media: | Water | Port Size: | Flanged | Place of Origin: | China (Mainland) |

Model Number: | CVE | Brand Name: | CMAX | Application: | General |

Design Standard: | BS EN 593 | Color: | bule/red/customized | Connection Ends: | BS EN 1092 PN 10/PN16 |

Temperature: | -29°~+425° | Port size: | NPS 2"-42" | Working Pressure: | PN10/PN16 |

Temperature Pressure: | 0℃ to 80℃ | Coating: | Fusion Bonded Epoxy | Operation type: | water |

Surface: | Powder coating/Acid pickling/Paint |

Packaging & Delivery

Packaging Details: Standard export package or as per your requirements

Delivery Detail: 25 days from date of order

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 |

Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting |

Valve Spring |

Stainless Steel |

- Q:Which kind of steam check valve is good?

- Steam check valve selection spring pressure check valve is better, can be sealed tight.Check valve, also known as one-way valve or check valve, its role is to prevent the medium back in the pipeline. Pump water off the bottom valve check valve also belongs to class. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.

- Q:40 how large check valves are installed in the water pipes?

- Crown valve press40 of the pipe outer diameter of 48 DN40 check valve on it

- Q:How many kinds of structure are there in the check valve?

- 3 butterfly check valve structure similar to butterfly valve, its structure is simple, flow resistance is small, water hammer pressure is smaller;4, diaphragm type check valve has a variety of forms, are used as the opening and closing the diaphragm, due to its good waterproof performance, simple structure, low cost, rapid development in recent years, but the use of diaphragm valve temperature and pressure by the diaphragm material limited;

- Q:What does the H/F/P stand for in the check valve H41H/H41F/H41P?

- Respectively, the valve seat sealing surface is made of alloy / fluorine plastic / stainless steel.

- Q:What does the check valve "H41F" mean?

- According to the provisions of the JB/T 308-2004 valve type programming method:H== check valve4== connection: flange type1== structure form: lifting typeF== sealing surface material: fluorine plastic

- Q:What kind of check valve is used in the sewage pump of sewage treatment plant?

- 3. to prevent hydraulic impact on the check valve sealing surface damage protection measures, check valve settings, to prevent the backflow of material, pump impeller to avoid the impact of the role of liquid. But as for the check valve itself, improper setting will cause a sudden impact of the disc on the valve seat by the water hammer, and damage the check valve sealing surface. Therefore, several protective measures should be taken. 1, for the pump outlet set >80mm swing check valve, horizontal installation should be adopted to weaken the valve seat back and the impact. 2, for the pump outlet check valve >=150mm diameter of the pipeline, should be placed before and after the bypass valve, to prevent the pressure before the valve rises too high, the check valve sealing surface damage. 3, the pump discharge pipeline starting and ending pressure is higher, the pipeline is not allowed to set the bypass, you can take the following measures. Set up safety valve instead of bypass valve. The action is similar to that of the bypass valve. It is located near the check valve outlet. When the water hammer causes the pressure to rise, a part of the water can be released to prevent the damage caused by the pressure rising. An air or inert gas buffer tank can be set. It is located near the check valve outlet, and when the water hammer is produced, the pressurized gas is compressed through the buffer tank to alleviate the pressure rise caused by the water hammer.

- Q:Butterfly check valve should be equipped with special flange for butterfly valve

- No, with a special appearance Jansen point flange butterfly valve. It can barely be installed without special flanges

- Q:What's the W in the check valve H44W?

- First, the meaning of "W" in check valve H44W:The H44W in the check valve W represents the seat of the check valve, and the sealing surface or lining material is the body sealTwo, check valve H44W model significanceLetter H: stands for check valveFirst number 4: the driving mode is the positive gearSecond numbers 4: the connection form is the flange

- Q:What is the function of the check valve in the pipeline?

- Check valve, also known as one-way valve or check valve, its role is to prevent the medium back in the pipeline.Pump water off the bottom valve check valve also belongs to class. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valve is automatic valve, check valve is mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.The installation of the check valve shall pay attention to the following1. Do not allow the check valve to bear weight in the line. The large check valve shall be independently supported so as not to be affected by the pressure caused by the piping system. 2, installation, pay attention to medium flow direction should be in accordance with the body of the ticket arrow direction.3, vertical lift check valve should be installed on the vertical pipe.4, lift type horizontal check valve should be installed in the horizontal pipe.

- Q:Is the check valve behind or behind the gate valve? Why?

- Thank youPlease install it in frontWhat about the front?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CHECK VALVE SWING DUCTILE IRON/ WCB DN40- DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords