PPR Ball Valve wtih Steel Ball High Quality

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: Plastic

Technics: Injection

Type: Valve

Place of Origin: China (Mainland)

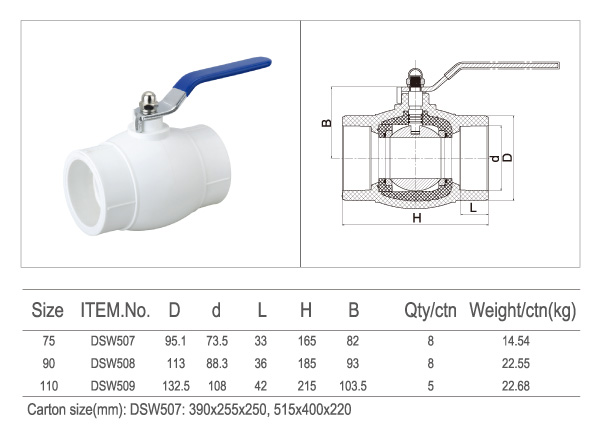

Model Number: 507-509

Connection: Welding

Shape: Equal

Head Code: Round

Standard: ISO,DIN,EN,MSS,API,BS,ANSI

Certification: ISO9001,CE

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Packaging & Delivery

Packaging Details:

1. Large carton:515x400x220 Cubage:0.04532 M3

Small carton:390x255x250 Cubage:0.0248 M3

2. PE poly bag+ cartonDelivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

- Q:Are plastic pipe fittings resistant to UV degradation in outdoor installations?

- Yes, plastic pipe fittings are generally resistant to UV degradation in outdoor installations. They are designed to withstand exposure to sunlight and do not easily degrade or become brittle when exposed to UV rays. However, it is important to note that the longevity of plastic pipe fittings can vary depending on the specific type of plastic used and the intensity and duration of UV exposure. It is recommended to choose fittings specifically designed for outdoor use and to follow manufacturer guidelines for proper installation and maintenance.

- Q:Can plastic pipe fittings be used in water park systems?

- Yes, plastic pipe fittings can be used in water park systems. Plastic pipe fittings are commonly used due to their durability, corrosion resistance, and affordability. They can effectively handle the water flow and pressure requirements of a water park system, making them a suitable choice for such applications.

- Q:Are plastic pipe fittings suitable for use in wineries and breweries?

- Yes, plastic pipe fittings are suitable for use in wineries and breweries. They are commonly used in these industries due to their corrosion resistance, durability, and ease of installation. Plastic fittings are also compatible with a wide range of chemicals and can withstand the high temperatures and pressures often encountered in winemaking and brewing processes.

- Q:What are the specifications of PVC tubes?

- PVC drainage specifications, I know, 200mm-2500mm caliber, Shandong Mu Feng plastic pipe to do drainage that piece is pretty good, you can look at, as if the largest domestic should be able to do three meters caliber

- Q:What are the different sizes of plastic pipe fittings available?

- There are various sizes of plastic pipe fittings available, ranging from as small as ¼ inch to as large as 24 inches in diameter. The specific sizes of fittings depend on the type of plastic pipe being used and the application it is intended for.

- Q:Can plastic pipe fittings be used for fuel transfer systems?

- No, plastic pipe fittings are generally not recommended for use in fuel transfer systems due to their potential to degrade or become brittle when exposed to certain fuels, leading to leaks or failures. It is advisable to use fittings specifically designed and approved for fuel transfer applications, such as those made from materials like brass or steel.

- Q:Can plastic pipe fittings be used for industrial waste disposal systems?

- Yes, plastic pipe fittings can be used for industrial waste disposal systems. Plastic pipe fittings, such as PVC or CPVC, are commonly used in various industrial applications due to their resistance to chemicals and corrosion. They are durable, cost-effective, and provide a reliable solution for managing industrial waste disposal systems.

- Q:How do plastic pipe fittings compare to galvanized steel fittings?

- Plastic pipe fittings offer several advantages compared to galvanized steel fittings. Firstly, plastic fittings are lightweight and easy to install, making them a cost-effective option. They also do not corrode or rust like galvanized steel fittings, which ensures long-term durability and reduces maintenance requirements. Additionally, plastic fittings are resistant to chemicals and have a smooth interior surface, minimizing friction and allowing for better flow. On the other hand, galvanized steel fittings are known for their strength and high-temperature resistance, making them suitable for specific applications where durability is crucial. Ultimately, the choice between plastic and galvanized steel fittings depends on the specific requirements of the project.

- Q:How do you remove plastic pipe fittings?

- To remove plastic pipe fittings, you can follow these steps: 1. First, turn off the water supply to the pipe you are working on. This will prevent any leaks or water damage during the removal process. 2. Use a pair of pliers or a wrench to loosen the fitting. Grip the fitting firmly and rotate it counterclockwise to loosen it. If the fitting is stuck or too tight, you can use a pipe wrench or adjustable spanner for more leverage. 3. Once the fitting is sufficiently loosened, you can try pulling it straight off the pipe. If it doesn't come off easily, you can use a pipe cutter or hacksaw to carefully cut the plastic pipe just above the fitting. This will allow you to remove the fitting without damaging the rest of the pipe. 4. After removing the fitting, inspect the pipe for any damage or debris. Clean the pipe and fitting ends thoroughly before installing a new fitting. Remember to take necessary precautions, such as wearing gloves and eye protection, as you work with tools and potentially sharp edges.

- Q:What are the potential drawbacks of using plastic pipe fittings?

- Some potential drawbacks of using plastic pipe fittings include their susceptibility to cracking or breaking under certain conditions, limited resistance to high temperatures or extreme weather conditions, and potential for chemical reactions with certain substances. Additionally, plastic pipe fittings may have lower durability and lifespan compared to other materials, such as metal fittings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Ball Valve wtih Steel Ball High Quality

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords