Correcting smell dental floss suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Correcting smell dental floss suitable for children

| Brand | Ok Floss |

| Floss material | UHMWPE |

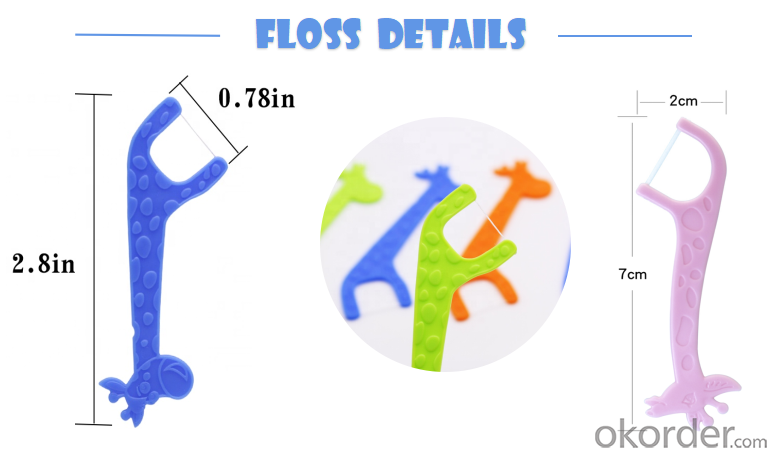

| Size | Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea /fruit |

| Color | white,yellow,orange |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Restaurant |

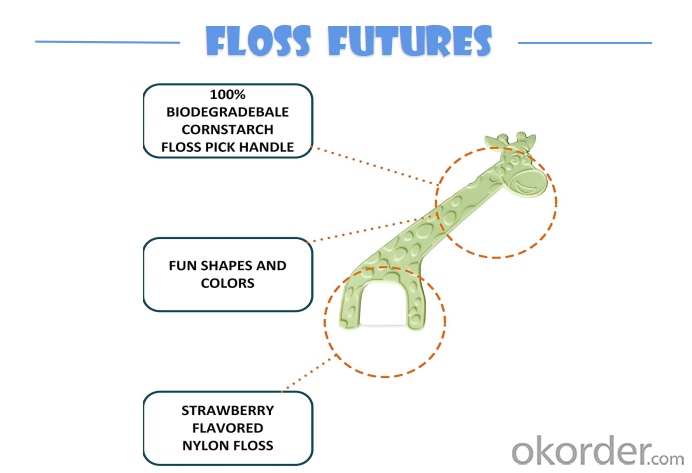

| Shape | Bear,Giraffe |

| Lead time | 20-30days |

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:What are the considerations for selecting medical plastic for minimally invasive surgery?

- When selecting medical plastic for minimally invasive surgery, some key considerations include biocompatibility, sterilization compatibility, mechanical properties, transparency, and resistance to chemicals and bodily fluids. Biocompatibility ensures that the material will not cause any adverse reactions or tissue damage when in contact with the body. Sterilization compatibility is important to ensure that the plastic can be effectively sterilized without compromising its properties. Mechanical properties such as flexibility, strength, and elasticity are crucial for the success of surgical procedures. Transparency allows for better visualization during the surgery, aiding surgeons in their precision. Lastly, resistance to chemicals and bodily fluids is necessary to ensure the longevity and reliability of the medical plastic in the surgical environment.

- Q:What are the most common concerns or complaints related to medical plastics?

- The most common concerns or complaints related to medical plastics usually revolve around issues such as potential toxicity, environmental impact, and the risk of contamination.

- Q:How is medical plastic used in neonatal care?

- Medical plastic is extensively used in neonatal care for various purposes. It is used for manufacturing medical devices and equipment that are crucial for the care and treatment of premature or sick newborns. Some common examples include plastic incubators, respiratory equipment like ventilators and oxygen masks, feeding tubes, catheters, and syringes. Medical plastic is chosen for these applications due to its biocompatibility, flexibility, durability, and ease of sterilization. It helps create a safe and sterile environment for neonates while ensuring accurate diagnosis, treatment, and monitoring of their health conditions.

- Q:What are the considerations for preventing leaching of chemicals from medical plastic?

- There are several key considerations for preventing leaching of chemicals from medical plastic. First and foremost, the selection of suitable plastic materials is crucial. Medical-grade plastics should be chosen carefully, ensuring they meet regulatory standards and have low levels of extractable substances. Proper testing and certification of the plastic materials should also be conducted to ensure their suitability for medical applications. Additionally, the manufacturing process plays a significant role in preventing chemical leaching. Strict control and monitoring of the production environment, including temperature and humidity, can help prevent the degradation of plastic and the release of chemicals. It is important to use techniques such as cleanroom manufacturing to minimize contamination and ensure the purity of the final product. Proper storage and handling of medical plastic products are equally important. Exposure to extreme temperatures, sunlight, or harsh chemicals can accelerate the leaching process. Therefore, storing medical plastic in controlled environments and following recommended storage guidelines can help prevent chemical leaching. Regular inspection and maintenance of medical plastic products are also necessary to ensure their integrity and prevent degradation over time. Monitoring for any signs of wear, cracks, or deterioration can help identify potential leaching risks and allow for timely replacements or repairs. Overall, a combination of careful material selection, stringent manufacturing processes, appropriate storage and handling, and regular maintenance are essential considerations for preventing the leaching of chemicals from medical plastic.

- Q:How does medical plastic contribute to medical device innovation?

- Medical plastic plays a crucial role in driving medical device innovation due to its unique properties and versatility. Its lightweight nature, durability, and ability to be molded into complex shapes make it an ideal material for manufacturing various medical devices. From surgical instruments to implantable devices, medical plastics offer exceptional biocompatibility and sterilization capabilities, ensuring patient safety and reducing the risk of infection. Furthermore, the flexibility of medical plastics allows for the creation of intricate designs and miniaturized components, enabling the development of advanced, minimally invasive medical devices that improve patient outcomes and revolutionize healthcare practices.

- Q:Barrier properties of plastic packaging, including separation of what?

- 1, capacity: due to the particularity of packaging and medication, from a few milliliters to 1000 ml or so, most of the shape is round, there are square, oval and other shapes.2, in order to ensure that drugs in the period of validity is not damp or not degenerate, medicinal plastic bottles should have good sealing and permeability, can prevent light, heat, water vapor, oxygen and other drugs.Direct contact with the inner wall, and 3 bottles of medicine bottle materials must comply with the requirements of pharmaceutical packaging, in order to ensure the safety of drugs.

- Q:Are medical plastics safe for human use?

- Yes, medical plastics are generally safe for human use. These plastics are specifically designed and manufactured to meet stringent safety and quality standards. They undergo rigorous testing to ensure they are biocompatible, non-toxic, and resistant to chemicals and bodily fluids. Additionally, medical plastics are often used in various healthcare applications, such as surgical instruments, implants, and drug delivery systems, without causing harm to patients.

- Q:Can medical plastic be safely used in pediatric patients?

- Yes, medical plastic can be safely used in pediatric patients.

- Q:Can medical plastic be safely used in geriatric applications?

- Yes, medical plastic can safely be used in geriatric applications. Medical plastics are specially designed to meet the unique needs of the healthcare industry, including geriatric care. They are durable, non-toxic, and resistant to bacteria, making them suitable for a wide range of medical devices and equipment used in geriatric care settings. Additionally, medical plastics can be easily cleaned and sterilized, ensuring the safety and well-being of elderly patients.

- Q:What material is disposable medical plastic bag made of?

- Polyvinyl chloride, referred to as PVC, and the formula is (CH - CH) n, is the most important kind of vinyl polymer, is the world's second largest plastic varieties after polyethylene. In China, the yield is the first in plastics. In the printing industry, packaging production of books, folders, tickets and other frequently used PVC calendered film cover color and transparent glazing film.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Correcting smell dental floss suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords