Biodegradable sanitary floss with toothpick natural floss rolls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

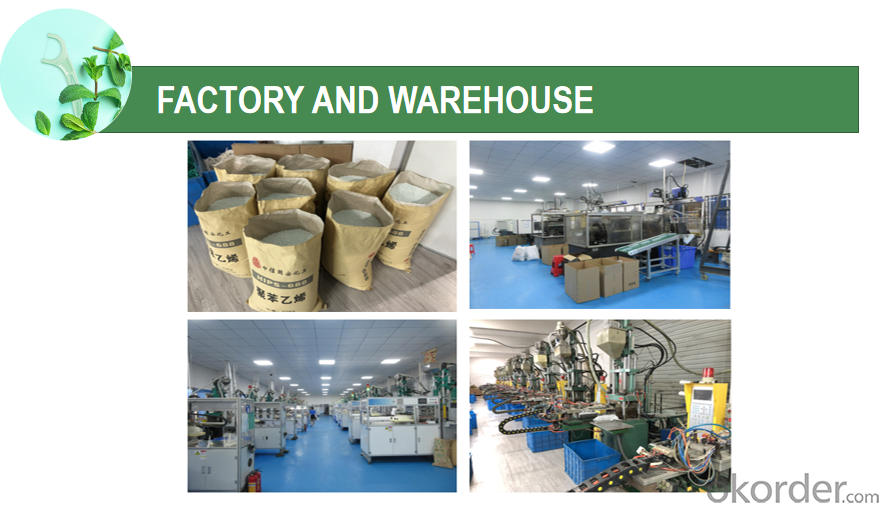

- Supply Capability:

- 100000 bag/month

- Option:

- Bamboo charcoal

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

100% Biodegradable Dental Floss Pick Eco-Friendly Flosser With Tooth Pick Natural Dental Floss Pick

| Brand | OEM/Ok Floss |

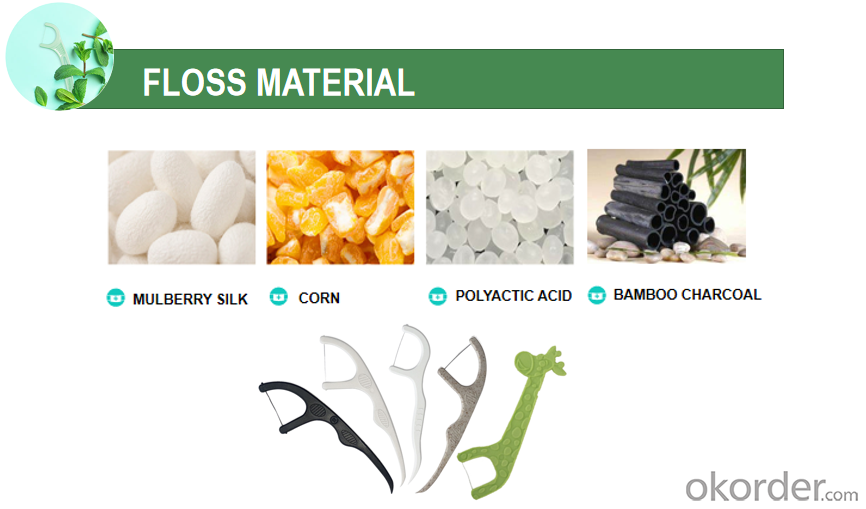

| Floss material | Charcoal ,UHMWPE ,nylon |

| Floss length | 7.4*2.2cm/25-30M/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

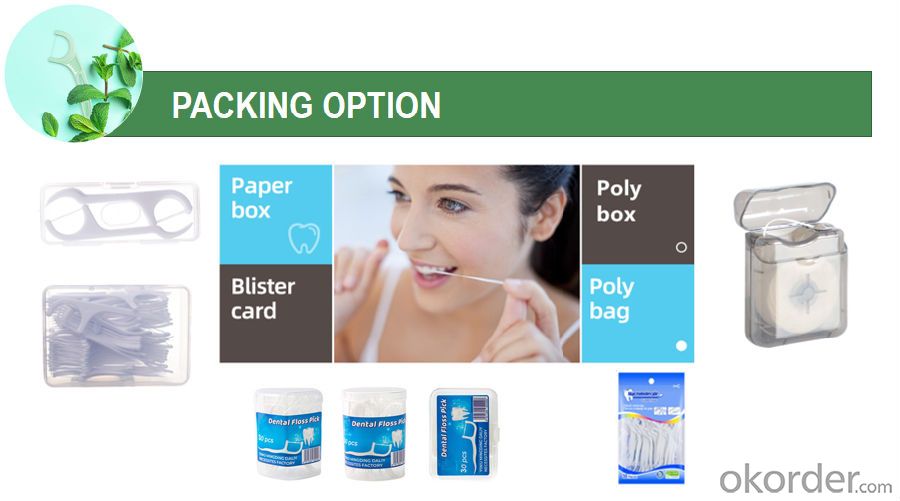

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:How does medical plastic help in preventing contamination during surgeries?

- Medical plastic helps in preventing contamination during surgeries in several ways. Firstly, it is used to manufacture sterile and disposable equipment, such as surgical gloves, gowns, and masks, which provide a barrier against pathogens and reduce the risk of cross-contamination between patients and healthcare professionals. Additionally, medical plastic is used to create single-use items like syringes, catheters, and surgical instruments, which eliminate the need for sterilization and minimize the chances of infection transmission. The non-porous nature of medical plastic also prevents the absorption of fluids and microorganisms, ensuring a hygienic surgical environment. Overall, the use of medical plastic in surgical settings plays a crucial role in maintaining cleanliness and reducing the spread of infections.

- Q:How do medical plastics contribute to patient safety?

- Medical plastics contribute to patient safety in several ways. Firstly, they are used in the manufacturing of various medical devices and equipment, such as syringes, IV tubes, and catheters, which are essential for delivering medications and treatments to patients. These plastics are designed to be sterile, ensuring a clean and hygienic environment during medical procedures, thus reducing the risk of infection and cross-contamination. Additionally, medical plastics are often used in the production of protective gear, such as gloves, masks, and gowns, which healthcare professionals rely on to safeguard themselves and patients from potential pathogens. These materials provide a barrier against bacteria and viruses, preventing the spread of infections in healthcare settings. Furthermore, medical plastics are crucial in the development of implantable devices, such as artificial joints, pacemakers, and prosthetics. These plastics are biocompatible, meaning they are well-tolerated by the human body and do not cause adverse reactions. This ensures that patients can receive necessary treatments or replacements without experiencing complications or rejection. Overall, medical plastics play a vital role in enhancing patient safety by providing sterile environments, preventing infections, and enabling the development of safe and effective medical devices.

- Q:How do medical plastics contribute to the efficiency of medical procedures?

- Medical plastics contribute to the efficiency of medical procedures by providing numerous benefits such as lightweight and durable materials, which make medical devices more portable and easier to handle. Additionally, medical plastics are sterile, reducing the risk of contamination and infection. They also offer flexibility, allowing for the creation of complex and customized medical tools. Furthermore, these plastics are transparent, enabling healthcare professionals to monitor patients’ conditions and evaluate treatment effectiveness. Overall, medical plastics enhance efficiency by improving the safety, functionality, and effectiveness of medical procedures.

- Q:How does medical plastic contribute to wound care products?

- Medical plastic contributes to wound care products in several ways. First, it provides a sterile and safe environment for wounds to heal, as it is non-reactive and resistant to bacteria. Second, it offers flexibility and elasticity, allowing wound dressings and bandages to conform to different body parts and movements, ensuring optimal comfort and functionality for patients. Additionally, medical plastic can be designed to have specific properties like moisture management, breathability, and adhesion, which are crucial for promoting wound healing and preventing infections. Overall, medical plastic plays a vital role in the development of advanced wound care products that enhance the healing process and improve patient outcomes.

- Q:How do medical plastics contribute to the ease of maintenance of medical devices?

- Medical plastics contribute to the ease of maintenance of medical devices in several ways. Firstly, these plastics are lightweight and durable, making them easy to handle and transport. Secondly, they are resistant to chemicals and sterilization processes, allowing for efficient cleaning and disinfection. Additionally, medical plastics can be molded into complex shapes, enabling the design of intricate device components that are easier to assemble and disassemble for maintenance. Lastly, these plastics have low friction properties, reducing wear and tear on moving parts and extending the lifespan of medical devices, ultimately simplifying the overall maintenance process.

- Q:How does medical plastic help in orthopedic applications?

- Medical plastic is highly beneficial in orthopedic applications as it offers several advantages. Firstly, it is lightweight and durable, making it suitable for the production of implants and prosthetics that need to withstand the stresses and strains of the human body. Additionally, medical plastic is biocompatible, meaning it does not cause any adverse reactions or allergies when it comes into contact with the body. This property allows for safer and more effective orthopedic procedures. Moreover, plastic materials can be easily molded into complex shapes, ensuring that implants and devices fit accurately and comfortably within the patient's body. Overall, medical plastic plays a crucial role in improving patient outcomes and enhancing the quality of orthopedic treatments.

- Q:How do medical plastics contribute to infection control?

- Medical plastics play a vital role in infection control by providing a hygienic and sterile environment in healthcare settings. They are used to manufacture various medical devices and equipment, such as syringes, catheters, and surgical instruments, which greatly reduce the risk of transmitting infections. These plastics are non-porous and easy to clean, allowing for effective sterilization and preventing the growth and spread of harmful bacteria and viruses. Additionally, medical plastics are often disposable, minimizing the chances of cross-contamination and ensuring a higher level of patient safety.

- Q:How does medical plastic contribute to the development of wound closure systems?

- Medical plastic plays a crucial role in the development of wound closure systems by providing materials that are biocompatible, flexible, and sterile. These properties allow for the creation of various devices such as sutures, staples, and adhesive strips that effectively close wounds, promote healing, and minimize the risk of infection. Additionally, medical plastic can be designed to have specific properties such as absorbability or non-reactivity, further enhancing its contribution to the development of advanced wound closure systems.

- Q:What are the different types of medical plastic packaging?

- There are several types of medical plastic packaging, including blister packs, vials, bottles, pouches, trays, and bags. These packaging options are designed to ensure the safety, sterility, and integrity of medical devices, pharmaceuticals, and other healthcare products.

- Q:What medical devices are used to get plastic injection molded parts?

- Many products are plastic injection molded parts, sputum suction tubes, infusion sets, dialysis pipes, etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Biodegradable sanitary floss with toothpick natural floss rolls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

- Supply Capability:

- 100000 bag/month

- Option:

- Bamboo charcoal

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords