Children's Safe Flavoring Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Children's Safe Flavoring Dental Floss Pick

| Brand: | OEM/Ok Floss |

| Floss material: | UHMWPE,Charcal as customized |

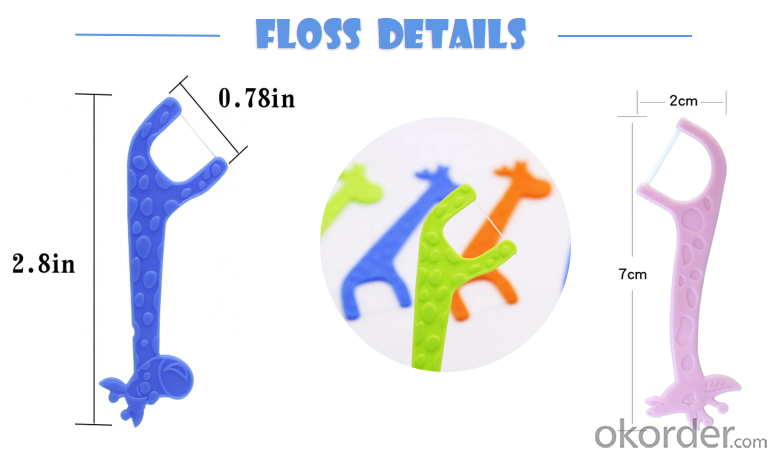

| Size: | Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm |

| Wax: | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor: | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color: | Floss original color |

| Floss original color: | Individual bulk PP bag/individual paper box/as customized |

| Applications: | Family,Hotel,Travel,Supermarket |

| Shape: | Bear,Giraffe,Cola |

| Lead time: | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OEM SERVICE SMALL MOQ FACTORY PRICE HIGH QUALITY INTERNATIONAL CERTIFICATE

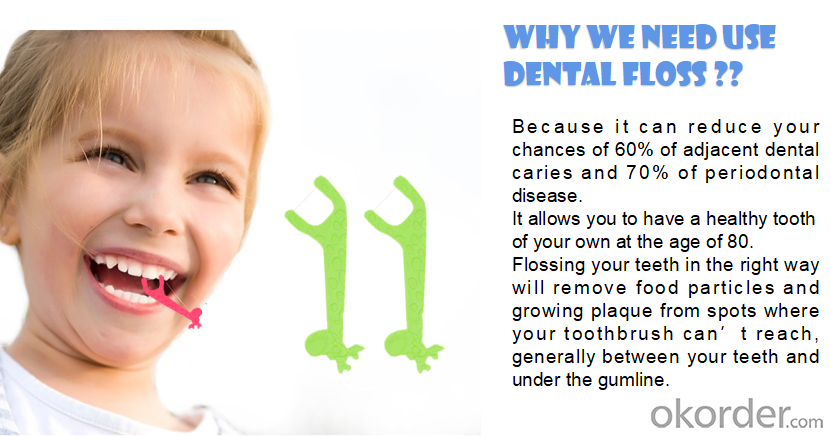

REDUCE ADJACENT DENTAL CARIES

DENTAL FLOSS FOR KIDS

FOOD-GRAD MATERIAL; FIBER FLOSS;MULBERRY SILK POLYACTIC ACID BAMBOO CHARCOAL

DENTAL FLOSS DETAILS & SIZE

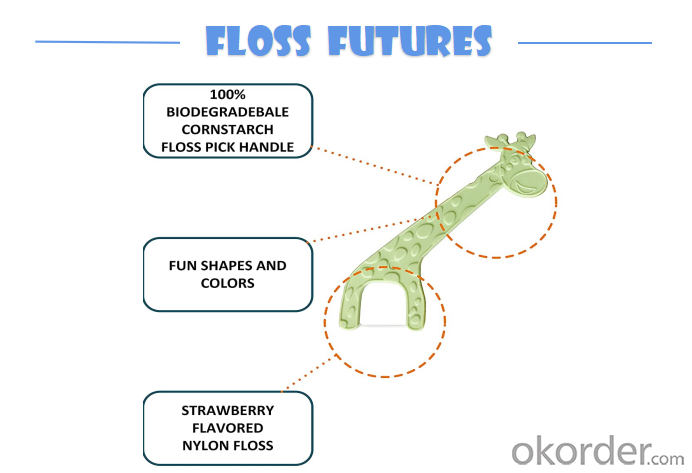

100% BIODEGRADEBALE CORNSTRACH FLOSS PICK HANDLE;FUN SHAPES AND COLORS

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:What are the factors that affect the moisture resistance of medical plastics?

- There are several key factors that can affect the moisture resistance of medical plastics. These factors include the type of plastic material used, the level of moisture exposure, the presence of additives or fillers, the manufacturing process used, and the overall design and construction of the medical device. Additionally, factors such as temperature, pressure, and the specific environment in which the medical plastic is used can also play a role in its moisture resistance.

- Q:How is medical plastic used in fertility treatments?

- Medical plastic is commonly used in fertility treatments for various purposes. It is used to manufacture devices such as catheters, syringes, and test tubes that are essential for procedures like in vitro fertilization (IVF), intrauterine insemination (IUI), and sperm retrieval. These plastic materials are biocompatible, sterile, and can be designed with precise dimensions to ensure accuracy and safety during these delicate procedures. Additionally, medical plastic is also used to create storage containers for frozen embryos and sperm, providing a reliable and secure environment for their preservation.

- Q:How is medical plastic used in radiology applications?

- Medical plastic is used in radiology applications primarily in the form of radiolucent materials, such as plastics and polymers, that are transparent to X-rays. These materials are used to manufacture various devices and components, including X-ray cassettes, positioning aids, immobilization devices, and patient supports. By using medical plastic in radiology, healthcare professionals are able to obtain high-quality X-ray images without any interference or obstruction caused by the materials used in the devices.

- Q:What are the main challenges in developing medical plastics?

- One of the main challenges in developing medical plastics is ensuring their biocompatibility, as they need to be safe for use inside the human body. Additionally, medical plastics must possess the necessary mechanical properties to withstand different medical procedures and be able to integrate seamlessly with other medical devices. Another challenge is the need for sterilization, as medical plastics must undergo rigorous sterilization processes without compromising their physical or chemical integrity. Furthermore, the development of medical plastics requires strict adherence to regulatory standards and certifications, adding another layer of complexity to the process. Overall, balancing safety, functionality, compatibility, and regulatory compliance are the key challenges in developing medical plastics.

- Q:Are there any potential risks associated with the release of microplastics from medical plastics?

- Yes, there are potential risks associated with the release of microplastics from medical plastics. These tiny plastic particles can accumulate in the environment and have the potential to enter the food chain, posing risks to both human health and ecosystem health. Studies have shown that microplastics can absorb and carry toxic chemicals, which can then be transferred to organisms upon ingestion. Additionally, the presence of microplastics in water bodies can have detrimental effects on marine life, disrupting their feeding and reproductive processes. Therefore, it is crucial to address and mitigate the release of microplastics from medical plastics to minimize these potential risks.

- Q:Can plastics and rubber roll over sound?

- Ultrasonic welding can not be used, you can make a groove in the plastic parts, EPDM rubber ring into the card, and if it is more insurance, you can use adhesive EPDM rubber, very good 3M4799, or direct bonding with 3M4799

- Q:Can medical plastics be made antimicrobial?

- Yes, medical plastics can be made antimicrobial through the incorporation of antimicrobial agents or additives during their manufacturing process. These agents help to inhibit the growth of microorganisms on the surface of the plastic, thereby reducing the risk of infections and improving overall hygiene in medical settings.

- Q:Can medical plastics be used for immune system-related treatments?

- Yes, medical plastics can be used for immune system-related treatments. They offer several advantages such as biocompatibility, durability, and the ability to be fabricated into complex shapes. Medical plastics can be used to create devices like catheters, implants, and drug delivery systems that can directly interact with the immune system to treat various conditions and diseases.

- Q:How does medical plastic help in minimizing the risk of infection transmission?

- Medical plastic helps in minimizing the risk of infection transmission by offering a hygienic and sterile surface that can be easily cleaned and disinfected. It is designed to be impermeable, preventing the infiltration of bacteria or viruses. Medical plastic also allows for the use of disposable medical devices, reducing the chances of cross-contamination. Its non-reactive nature and ability to withstand harsh cleaning agents make it an essential material for medical equipment, surfaces, and packaging, contributing to a safer healthcare environment.

- Q:How is medical plastic used in sports medicine?

- Medical plastic is used in sports medicine for various purposes. It is commonly used to create splints, braces, and orthotic devices that provide support and stability to injured joints or body parts. Medical plastic is also used to manufacture prosthetics for athletes who have lost limbs or require artificial limbs due to injuries. Additionally, medical plastic is used in the production of surgical tools and equipment used in sports-related surgeries and procedures. Overall, medical plastic plays a crucial role in sports medicine by aiding in injury prevention, rehabilitation, and enhancing the overall performance of athletes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Children's Safe Flavoring Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords