Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

- Option:

- 7.4*2.2cm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

Brand OEM/Ok Floss

Floss materialCharcoal ,UHMWPE ,nylon

Floss length7.4*2.2cm/25-30M/OEM

WaxImport germany wax/american wax/bee wax/candelilla wax/customized wax

FlavorMint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss original color

Floss original colorIndividual bulk PP bag/individual paper box/as customized

ApplicationsFamily,Hotel,Travel,Supermarket

DeliveryBy sea,By air,By express.

Lead time20-30days

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots where your

toothbrush can’t reach, generally between your teeth and under the gumline.

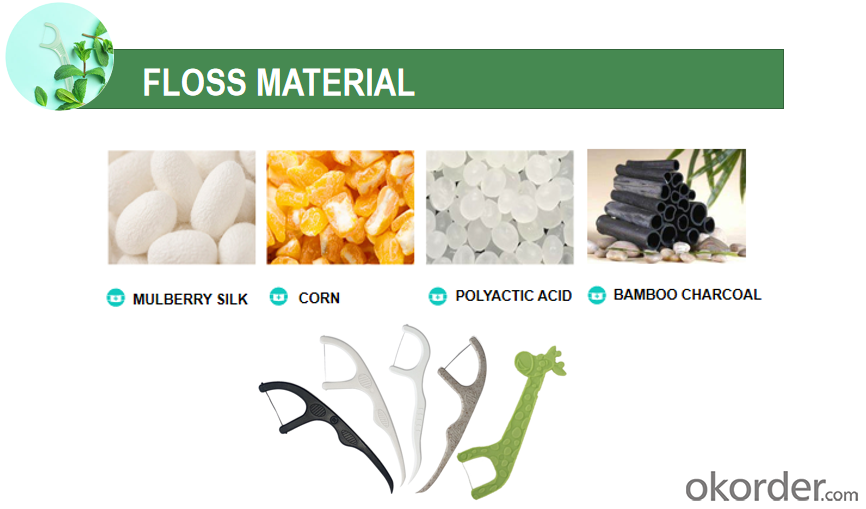

Various flavors to choose:Mulberry Silk,Corn, Polyactic Acid, Bamboo Chacoal, and any flavor you want.

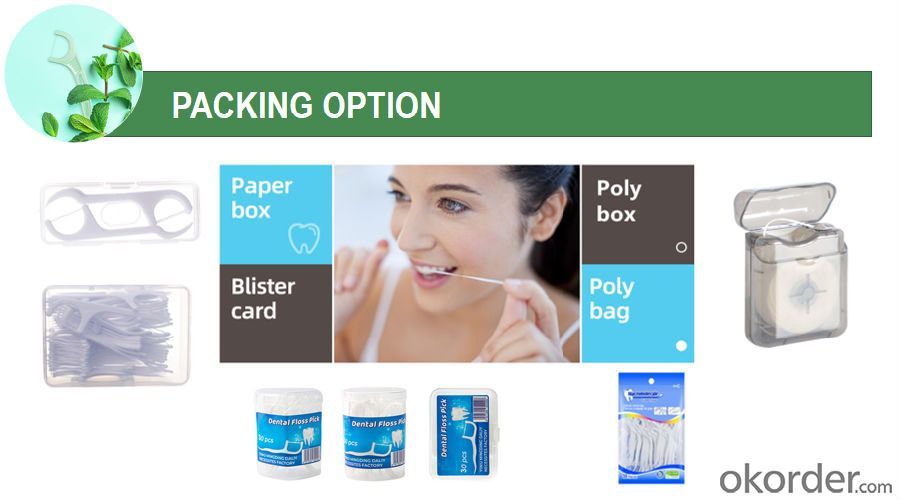

Many kinds of packaging options are available.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:How do medical plastics contribute to patient safety?

- Medical plastics contribute to patient safety in several ways. Firstly, they are used in the manufacturing of various medical devices and equipment, such as syringes, IV tubes, and catheters, which are essential for delivering medications and treatments to patients. These plastics are designed to be sterile, ensuring a clean and hygienic environment during medical procedures, thus reducing the risk of infection and cross-contamination. Additionally, medical plastics are often used in the production of protective gear, such as gloves, masks, and gowns, which healthcare professionals rely on to safeguard themselves and patients from potential pathogens. These materials provide a barrier against bacteria and viruses, preventing the spread of infections in healthcare settings. Furthermore, medical plastics are crucial in the development of implantable devices, such as artificial joints, pacemakers, and prosthetics. These plastics are biocompatible, meaning they are well-tolerated by the human body and do not cause adverse reactions. This ensures that patients can receive necessary treatments or replacements without experiencing complications or rejection. Overall, medical plastics play a vital role in enhancing patient safety by providing sterile environments, preventing infections, and enabling the development of safe and effective medical devices.

- Q:What are the potential allergic reactions to medical plastics?

- Potential allergic reactions to medical plastics can include skin irritation, redness, rash, itching, and in severe cases, allergic contact dermatitis.

- Q:What are the main applications of medical plastic in the healthcare industry?

- Medical plastic has a wide range of applications in the healthcare industry, including the production of medical devices such as syringes, IV tubing, catheters, and surgical instruments. It is also used for packaging and sterilization purposes, as well as in the manufacturing of prosthetics and dental materials. Additionally, medical plastic is utilized in drug delivery systems, implants, and various diagnostic equipment.

- Q:How are medical plastics sterilized?

- Medical plastics can be sterilized through various methods such as steam sterilization, ethylene oxide sterilization, gamma radiation, and electron beam irradiation. These processes effectively eliminate bacteria, viruses, and other microorganisms from the medical plastics, ensuring their safety and suitability for medical use.

- Q:What are the characteristics of medical plastics that make them suitable for medical devices?

- Medical plastics have several characteristics that make them highly suitable for medical devices. Firstly, they are biocompatible, meaning they do not cause any adverse reactions or toxicity when in contact with living tissues or fluids. This is crucial for ensuring patient safety and reducing the risk of complications. Secondly, medical plastics are lightweight and can be easily molded into complex shapes, allowing for the production of intricate medical devices. This flexibility in design is essential for creating devices that can fit specific anatomical structures or perform intricate functions. Additionally, medical plastics have excellent chemical resistance, which ensures that they can withstand exposure to various sterilization methods and harsh chemicals used in healthcare settings. This resistance to corrosion and degradation is vital for maintaining the integrity and longevity of medical devices. Furthermore, medical plastics possess excellent mechanical properties, such as high tensile strength and durability. This enables them to withstand the stresses and strains associated with medical device applications, including repeated use and sterilization cycles. Lastly, medical plastics are cost-effective compared to other materials, such as metals or ceramics, making them a popular choice for manufacturers. Their availability and affordability contribute to their widespread use in medical devices, ultimately benefiting patients and healthcare providers alike.

- Q:Can medical plastics be used in prosthetics or orthotics?

- Yes, medical plastics can be used in prosthetics or orthotics. These materials are often chosen for their durability, flexibility, and biocompatibility, making them suitable for creating custom prosthetic limbs or orthotic devices that provide support and aid in mobility for individuals with physical disabilities or injuries.

- Q:What are the considerations for selecting medical plastic for radiation therapy applications?

- When selecting medical plastic for radiation therapy applications, several considerations need to be taken into account. Firstly, the plastic material should have high radiation resistance to ensure it can withstand the radiation exposure without degrading or releasing harmful substances. Additionally, the plastic should have low attenuation properties, meaning it should not significantly absorb or scatter the radiation, as this could affect the accuracy of the treatment. The plastic should also be biocompatible, ensuring it does not cause any adverse reactions or toxicity when in contact with the patient's body. Other factors such as mechanical strength, dimensional stability, and ease of fabrication should also be considered to ensure the plastic can meet the specific requirements of radiation therapy applications.

- Q:Are medical plastics resistant to flammability?

- Yes, medical plastics are generally designed to be resistant to flammability. They are engineered to have high ignition temperatures and low flammability properties, making them suitable for use in medical devices where safety is crucial.

- Q:How is medical plastic used in telehealth devices?

- Medical plastic is used in telehealth devices primarily for their durability, versatility, and safety. It is commonly used for manufacturing components such as housing, connectors, and cables in telehealth devices. These plastic materials provide protection against impact, wear and tear, and resistance to chemicals, making them suitable for various medical applications. Additionally, medical plastics can be easily molded into complex shapes, ensuring a precise fit for different telehealth devices and improving patient comfort.

- Q:How is medical plastic used in healthcare?

- Medical plastic is used in healthcare for a wide range of applications, including medical devices, packaging materials, and even surgical instruments. It is a versatile material that is durable, lightweight, and can be easily sterilized, making it ideal for use in hospitals and clinics. Medical plastic is used to manufacture items such as syringes, IV tubes, catheters, prosthetics, and implants, enhancing patient care and facilitating various medical procedures. Additionally, it is crucial in maintaining a sterile environment by providing hygienic packaging for medications, dressings, and other medical supplies.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

- Option:

- 7.4*2.2cm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches