Powder and Emulsion Fiberglass Glass Fiber Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Powder and Emulsion Fiberglass Glass Fiber Chopped Strand Mat

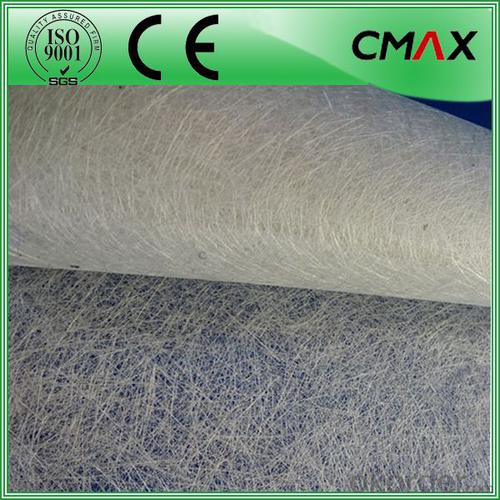

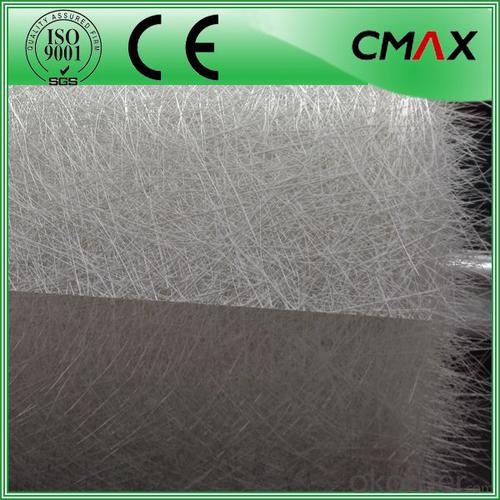

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

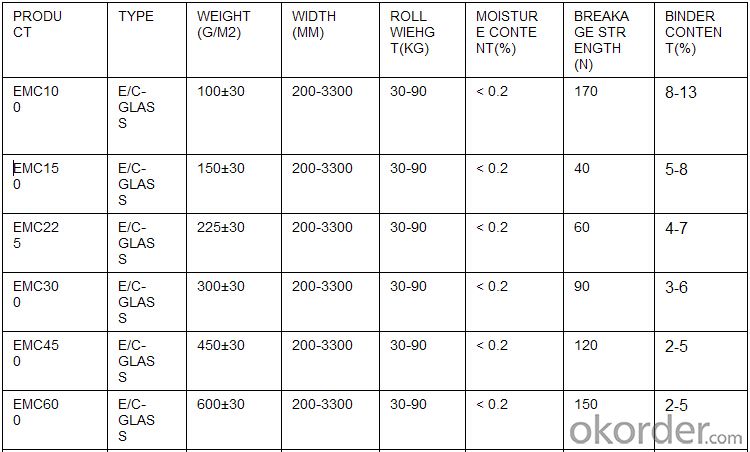

Technical Data:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q:How does fiberglass mat tissue perform in terms of moisture resistance?

- Fiberglass mat tissue performs excellently in terms of moisture resistance. Its dense structure and composition make it highly resistant to water absorption, preventing moisture from seeping through and causing damage to the underlying material. This property makes fiberglass mat tissue an ideal choice for various applications where moisture protection is crucial, such as in the construction of roofs, walls, and insulation.

- Q:Is the Teflon gasket filled with fiberglass or graphite?

- The molecular formula of E is similar to that of FFKM. FFKM is more resistant to temperature than PTFE, and has elasticity at 327 degrees!

- Q:How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue, widely utilized in industries such as construction, automotive, and marine, serves as a common type of reinforcement material. When evaluating fiberglass mat tissue in comparison to other reinforcement materials, several factors come into play. First and foremost, fiberglass mat tissue exhibits remarkable strength and durability. With its high tensile strength, it can endure substantial pulling or stretching forces without distorting or breaking. This strength is comparable, if not superior, to reinforcement materials like carbon fiber or aramid fibers. Furthermore, fiberglass mat tissue displays excellent resistance to chemical, moisture, and UV degradation, rendering it suitable for long-term usage in various environments. Another advantage of fiberglass mat tissue lies in its cost-effectiveness. In contrast to other reinforcement materials, fiberglass is relatively affordable, making it a popular choice for manufacturers and builders who require a cost-efficient solution without compromising quality. Its affordability expands its accessibility to a wider array of applications and industries. Moreover, fiberglass mat tissue is renowned for its versatility. It can be molded into different shapes and sizes, allowing for customization and flexibility in design. This adaptability makes fiberglass mat tissue suitable for a broad range of applications, ranging from simple repairs to complex structural reinforcements. However, it is important to note that fiberglass mat tissue may have certain limitations when compared to other reinforcement materials. For instance, it may not possess the same level of stiffness or strength as carbon fiber, which is often preferred in high-performance applications. Additionally, fiberglass mat tissue may exhibit lower resistance to impact or fatigue when compared to materials like aramid fibers. In conclusion, fiberglass mat tissue provides a favorable combination of strength, durability, cost-effectiveness, and versatility, making it a favored choice for numerous applications. While it may have some limitations when compared to other reinforcement materials, its overall performance and affordability render it a widely utilized and dependable option in various industries.

- Q:Can fiberglass mat tissue be used for insulating ductwork?

- Indeed, insulating ductwork can be accomplished by employing fiberglass mat tissue. This insulation material is characterized by its composition of delicate glass fibers. Its lightweight and pliable nature facilitate effortless installation around ductwork, ensuring optimal thermal insulation. The outstanding insulating qualities of fiberglass mat tissue serve to minimize heat loss or gain within ducts, effectively enhancing energy efficiency. Additionally, it aids in condensation reduction and noise attenuation. Furthermore, its resistance to moisture, fire, and pests renders fiberglass mat tissue a fitting option for insulating ductwork in diverse environments.

- Q:Can fiberglass mat tissue be used for insulation in cold environments?

- Yes, fiberglass mat tissue can be used for insulation in cold environments. Fiberglass is a common material used for insulation due to its excellent thermal properties. It has a low thermal conductivity, meaning it can effectively resist the transfer of heat, thus providing insulation in cold environments. Fiberglass mat tissue is specifically designed to provide thermal insulation and is commonly used in applications such as walls, roofs, and floors to prevent heat loss and maintain a comfortable temperature indoors. Additionally, fiberglass is resistant to moisture and does not easily degrade or lose its insulating properties in cold and damp conditions, making it a suitable choice for insulation in cold environments.

- Q:Can fiberglass mat tissue be used for reinforcement in composites?

- Yes, fiberglass mat tissue can be used for reinforcement in composites. It is commonly used as a reinforcement material in various composite applications due to its high strength, durability, and excellent bonding properties. The fiberglass mat tissue helps enhance the mechanical properties and structural integrity of the composite material.

- Q:Can fiberglass mat tissue be used in wet environments?

- Indeed, wet environments can indeed accommodate the utilization of fiberglass mat tissue. This specialized material has been ingeniously engineered to possess an inherent resistance to moisture, thereby enabling it to endure prolonged exposure to water. Consequently, this remarkable attribute renders it highly suitable for deployment in various sectors, most notably construction, marine, and automotive industries. These particular domains frequently necessitate the deployment of components or structures that inevitably encounter water, humidity, or moisture. The material's unparalleled resistance to water impeccably guarantees the preservation of its structural robustness and ensures that it remains impervious to degradation or any diminishment in its performance properties even when confronted with damp conditions.

- Q:Can fiberglass mat tissue be used for insulation in refrigeration systems?

- Indeed, insulation in refrigeration systems can be accomplished by employing fiberglass mat tissue. Fiberglass, renowned for its remarkable thermal characteristics and moisture resistance, is a prevalent choice for insulation purposes. Specifically engineered to provide insulation, fiberglass mat tissue finds frequent application in the construction of refrigeration systems. Its purpose is to reduce heat transfer and uphold the desired temperature within the system. Moreover, fiberglass possesses the advantages of being lightweight, long-lasting, and easily installable, rendering it a favored option for refrigeration system insulation.

- Q:What are the different surface textures available for fiberglass mat tissue?

- Fiberglass mat tissue offers various surface textures for different purposes. One popular option is a sleek and polished smooth surface, achieved through the use of a smooth roller or mold during manufacturing. This texture is commonly used for applications that require a sophisticated finish. Another choice is a coarse or rough surface, suitable for applications that need better adhesion. It is accomplished by employing a textured roller or mold during manufacturing, resulting in a surface with small bumps or ridges that increase surface area for improved bonding with adhesives or coatings. A third option is a patterned or embossed surface, used in applications that require aesthetic appeal or enhanced grip. This texture is achieved by employing a patterned roller or mold, resulting in a surface with raised or recessed designs that can be visually appealing or provide added traction when used in flooring or decking materials. Furthermore, manufacturers have the flexibility to customize the surface texture of fiberglass mat tissue to meet specific requirements. This includes creating textured surfaces with specific patterns or designs tailored to individual needs or preferences. In summary, the diverse surface textures available for fiberglass mat tissue offer a wide range of applications, providing choices for smooth finishes, improved adhesion, aesthetic appeal, or enhanced grip.

- Q:What are the different quality standards for fiberglass mat tissue?

- Various quality standards are utilized to evaluate the quality of fiberglass mat tissue, ensuring its suitability for intended applications and meeting performance requirements. The ASTM D2178 standard is widely used to assess the quality of fiberglass mat tissue. This standard outlines the specifications for base materials used in the production of asphalt and coal tar roofing products. It covers physical properties such as weight, thickness, tensile strength, tear resistance, and permeability. Another recognized standard is ISO 3376, which provides guidelines for determining the tensile properties of nonmetallic materials, including fiberglass mat tissue. It defines test methods for parameters like tensile strength, elongation at break, and modulus of elasticity. In Europe, the EN 1871 standard is commonly used for assessing the quality of fiberglass mat tissue. This standard specifies the requirements for reinforced bitumen sheets used in roofing applications. It covers physical properties, dimensional stability, resistance to heat, and resistance to aging. Furthermore, there are industry-specific quality standards that may apply to fiberglass mat tissue used in particular applications. For instance, the ASTM C1666 standard specifically addresses fiberglass reinforced cementitious panels and sets requirements for the materials used in their production. Overall, these various quality standards for fiberglass mat tissue ensure that it meets specific performance criteria and can be effectively utilized in applications such as roofing, construction, and insulation. They establish a framework for manufacturers, suppliers, and customers to assess and compare the quality of different products in the market.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Powder and Emulsion Fiberglass Glass Fiber Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords