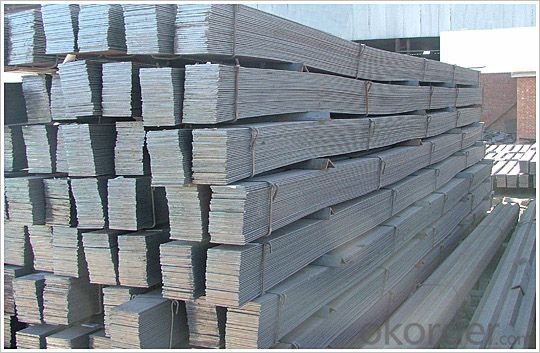

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy export packed |

| Delivery Detail: | 20-25 days |

Specifications

High Quality steel flat bar,flat steel,flat bar

1. Q235,Q345,SS400,ASTM A36,S235JR,S275JR

2. USD 495-516/Ton

3. Free Sample

flat steel,Steel Flat Bar, Galvanized Flat Bar,SS400 flat steel,galvanized flat steel

typical size range: | 10*3 – 300*25mm 6 – 12M Long (special lengths can also be provided) |

Available specifications: | EN 10025 GB/T704-2004 JIS G3101 |

Steel grades: | S235JR, S355JR, Q235B, Q345B, SS400 |

Application of Flat Bar

Flat Bar is used for general fabrication, making structures and frames. Mild Steel Flat Bar can be easily cut and drilled, and is particularly suited to welding. Examples of its use include furniture making, machinery manufacturing, shipbuilding, railway spare parts, iron towers, steel structures, and boilers.

1. What grades and standards of steel are used for your production?

Our grades could meet most of customers demand, such as ASTM, GB, JIS, EN etc…Specific grades include commercial quality, low carbon; high carbon and high strength select low alloys.

2. What type of finishes is your product produced in?

We produce steel product in a wide variety of finishes, including hot-rolled black, hot-rolled pickled & oiled, cold-rolled, aluminized, and hot dipped galvanized. If you have a specific finish that is required, please contact us for additional information.

3. What is your order minimum?

As an experienced steel materials manufacturer, we sell in one full container and combination container. Although the total weight on an order will vary due to the type and size, a typical full container load or less container load order will be approximately 15-25 tons.

4. What could we get if we build up relationship with you company?

Frankly, you get competitive price, good quality materials and considerable payment term. Our experienced team will offer you full service from order confirmation to goods arrival your warehouse. You have nothing to worry about during the process.

- Q:What is the maximum length of steel flat bars available?

- The maximum length of steel flat bars available can vary depending on the manufacturer and supplier. However, it is common to find steel flat bars in lengths ranging from 10 to 20 feet.

- Q:How do steel flat bars compare in terms of strength and durability?

- Steel flat bars are known for their exceptional strength and durability. Due to their flat shape, they offer enhanced load-bearing capacities and resistance to bending or warping. Additionally, steel flat bars are highly resilient against external impacts and corrosion. Overall, they are a reliable choice for applications requiring robustness and longevity.

- Q:Can steel flat bars be used for making brackets or supports for industrial machinery?

- Yes, steel flat bars can be used for making brackets or supports for industrial machinery. Steel flat bars are known for their strength, durability, and resistance to wear and tear, making them an ideal choice for providing structural support and stability to industrial machinery. Additionally, steel flat bars can be easily fabricated, welded, and customized to meet the specific requirements of different machinery, making them a versatile option for constructing brackets and supports.

- Q:Are steel flat bars suitable for making defense industry equipment or vehicles?

- Yes, steel flat bars are suitable for making defense industry equipment or vehicles. Steel is known for its exceptional strength and durability, making it an ideal material for constructing robust and reliable military equipment. Steel flat bars can be used to fabricate various components, such as armor plates, frames, chassis, and structural supports, which are essential for defense industry equipment and vehicles. Additionally, steel's versatility allows for customization, enabling manufacturers to meet specific requirements and ensure the desired level of protection and performance.

- Q:What are the different types of surface patterns available for steel flat bars?

- Steel flat bars come in various surface patterns, each with its own unique qualities and advantages. Some commonly used patterns include: 1. Smooth surface: This is the most basic and widely used pattern for steel flat bars. It has a plain and flat surface without any visible textures or patterns. A smooth surface is preferred when functionality is the main focus and appearance is not a priority. 2. Serrated surface: Serrated patterns feature small grooves or ridges along the length of the steel flat bar. This pattern provides enhanced grip and traction, making it suitable for applications where slip resistance is crucial, such as walkways, ramps, or stair treads. 3. Checker plate pattern: Also known as diamond plate or tread plate pattern, it features a raised diamond-shaped pattern on the surface. This pattern offers excellent slip resistance and is commonly used in industrial settings, loading docks, truck beds, or flooring applications. 4. Hammered pattern: Hammered patterns have a textured appearance resembling the marks left by a hammer. This pattern adds aesthetic appeal to the steel flat bar and is often used in decorative applications, such as architectural detailing or furniture. 5. Galvanized surface: Galvanization is a process where steel is coated with a layer of zinc to protect it from corrosion. Galvanized steel flat bars have a shiny and smooth surface, providing excellent corrosion resistance and durability. This pattern is commonly used in outdoor applications or areas prone to moisture exposure. 6. Painted or powder-coated surface: Steel flat bars can also be painted or powder-coated to achieve a specific color or finish. This pattern allows for customization and can be used to match the surrounding environment or for aesthetic purposes. When selecting the appropriate surface pattern for a steel flat bar, it is important to consider the intended use and requirements. Each pattern offers distinct advantages, and choosing the right one can ensure optimal performance and longevity in the intended application.

- Q:How do you calculate the weight of a steel flat bar?

- In order to determine the weight of a steel flat bar, it is necessary to have knowledge of both the bar's dimensions and the density of steel. Initially, one must measure the length, width, and thickness of the flat bar, utilizing inches or any other suitable unit of measurement. Subsequently, the volume of the bar can be calculated by multiplying the length, width, and thickness. The volume can be determined by employing the formula: Volume = Length x Width x Thickness. Following the acquisition of the volume, it may be necessary to convert it to cubic inches. Afterwards, the density of steel needs to be determined, usually measured in pounds per cubic inch (lbs/in³). The density of steel can slightly vary depending on the specific alloy, although a commonly used approximation is 0.2836 lbs/in³. Lastly, the weight can be derived by multiplying the volume of the flat bar by the density of steel, utilizing the formula: Weight = Volume x Density. For instance, if the dimensions of the steel flat bar are 12 inches in length, 2 inches in width, and 0.5 inches in thickness, the volume would be 12 x 2 x 0.5 = 12 cubic inches. Assuming the density of steel is 0.2836 lbs/in³, the weight of the steel flat bar would amount to 12 x 0.2836 = 3.4032 lbs. Therefore, the approximate weight of the steel flat bar would be around 3.4 pounds.

- Q:Galvanized flat steel how much is one meter?

- Formula of flat steel: width * thickness * 0.00785 (kg/m), zinc coating weight: 1.06Galvanized pipe formula: (outer diameter wall thickness) * wall thickness * 0.02466 * 1.06, DN25 galvanized pipe outer diameter 33.5, GB thickness 3.25, weight: 2.57kg/m, DN32, outer diameter 42.3, wall thickness 3.25, weight: 3.32kg/m. DN stands for nominal caliber.Angle formula (approximate): edge width * thickness * 0.015, 4# angle iron weight 2.422kg/m

- Q:Are steel flat bars suitable for marine applications?

- Yes, steel flat bars are suitable for marine applications. They are widely used in marine construction due to their high strength, durability, and corrosion resistance. The steel is typically treated to prevent rusting and withstand the harsh marine environment, making it a reliable choice for various marine applications such as shipbuilding, offshore platforms, and marine equipment.

- Q:What is the difference between flat steel and steel strip?

- It belongs to the conventional flat stainless steel series, steel to stainless steel sheet series, steel is cold rolled sheet, and a flat surface of hot rolled and cold rolled surface, flat iron is a common type of steel does not contain nickel, but sometimes some customers habitually called stainless steel flat steel flat iron.

- Q:How do steel flat bars differ from steel round bars?

- Steel flat bars and steel round bars differ in their shape and structural properties. The most obvious difference between steel flat bars and steel round bars is their shape. Steel flat bars are characterized by their rectangular shape with sharp edges and a flat surface on the top and bottom. On the other hand, steel round bars have a circular cross-section, resembling a rod or a cylinder. In terms of structural properties, steel flat bars and steel round bars also vary. Steel flat bars are often preferred for applications that require a high load-bearing capacity in a horizontal direction, such as supporting weight or providing structural stability. Their flat surface allows for better distribution of weight and helps prevent bending or warping under heavy loads. Steel round bars, on the other hand, are commonly used in applications that require strength and durability in various directions, including vertical and horizontal forces. The circular shape of round bars provides excellent resistance to bending and twisting, making them suitable for applications such as construction, machinery, and automotive components. Additionally, the manufacturing process for steel flat bars and steel round bars may also differ. Steel flat bars are typically produced by hot rolling, which involves passing heated steel through a series of rollers to achieve the desired shape. Steel round bars can be produced by both hot rolling and cold drawing processes, where the steel is either heated and passed through rollers or pulled through a die to form the circular shape. In summary, steel flat bars and steel round bars differ in terms of shape, structural properties, and manufacturing processes. Understanding these differences is crucial when selecting the appropriate steel bar for a specific application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords