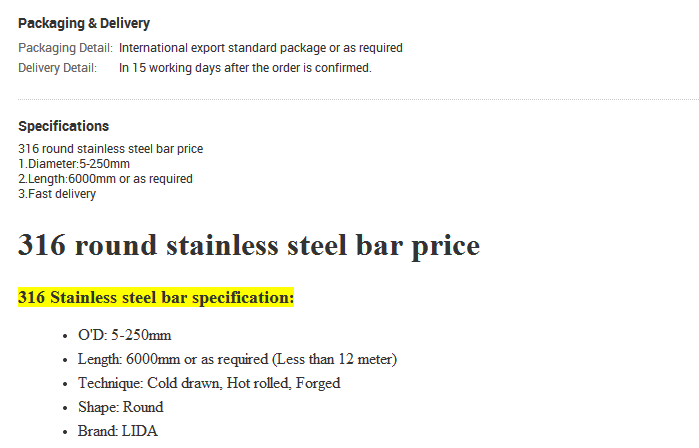

316 round stainless steel bar price for china manufacture

- Loading Port:

- Tianjin

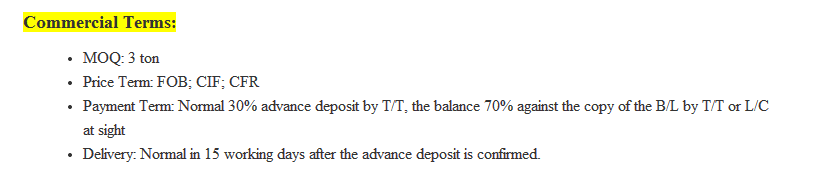

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Can stainless steel pipes be wrapped with tape?

- Stainless steel pipes can indeed be wrapped with tape. However, it is crucial to use the appropriate tape specifically designed for stainless steel. The reason for this is that stainless steel pipes are commonly utilized in industrial and high-temperature settings, and regular tapes may not endure the extreme conditions. Typically, stainless steel pipe tapes are constructed from materials like stainless steel foil or aluminum foil, along with a heat-resistant adhesive, guaranteeing long-lasting durability and resistance to corrosion. These tapes serve a variety of purposes, including insulation, sealing, and protection against abrasion. It is always advisable to consult the manufacturer's guidelines or seek professional advice prior to applying any tape to stainless steel pipes, ensuring correct installation and avoiding any potential issues.

- Q:Are stainless steel pipes suitable for power plant systems?

- Stainless steel pipes prove to be a suitable option for power plant systems. Stainless steel is renowned for its exceptional ability to resist corrosion, a critical characteristic required in power plant systems. These systems expose pipes to elevated temperatures, pressures, and various corrosive elements like water, steam, and chemicals. The stainless steel pipes demonstrate remarkable resistance to rust, oxidation, and scaling, ensuring their reliability and durability over extended periods of time in power plant operations. Moreover, the stainless steel pipes possess considerable strength, enabling them to endure the high pressure and stress commonly encountered in power plant systems. Additionally, they exhibit outstanding heat resistance, a crucial feature given the extreme temperatures to which the pipes are exposed in power plants. In summary, due to their corrosion resistance, strength, and heat resistance properties, stainless steel pipes enjoy widespread popularity as a favored choice in power plant systems.

- Q:Why can't stainless steel tubes be cut with acetylene?

- That is because the iron element in the high temperature, if the above 99,6% will occur on the oxygen oxidation phenomenon is very strong, because of the heat transfer cycle, in order to make the cutting to continue uninterrupted, continuous heating it when cutting calories.

- Q:What is the difference between polished and unpolished stainless steel pipes?

- Polished and unpolished stainless steel pipes differ primarily in their appearance and surface finish. Polished stainless steel pipes have undergone a polishing process that enhances their aesthetic appeal by creating a smooth, shiny, and reflective surface. This process involves using abrasive materials or compounds to remove any imperfections, scratches, or blemishes on the stainless steel surface. On the other hand, unpolished stainless steel pipes have a rougher, duller, and more industrial-looking surface. They have not been subjected to the polishing process and therefore retain their original surface finish, which may include slight imperfections, scratches, or a matte appearance. The choice between polished and unpolished stainless steel pipes depends on the desired application and aesthetic preference. Polished stainless steel pipes are commonly used in industries such as architecture, interior design, and food processing, where a visually appealing and hygienic surface is required. Unpolished stainless steel pipes, on the other hand, are often used in applications where appearance is not a priority, such as industrial or structural uses. It is important to note that the performance and durability of both polished and unpolished stainless steel pipes are comparable, as the polishing process does not affect the inherent corrosion resistance and strength of the stainless steel material. Ultimately, the decision between polished and unpolished stainless steel pipes relies on the specific requirements and intended use of the pipes.

- Q:Can stainless steel pipes be used for drinking water systems?

- Indeed, drinking water systems can utilize stainless steel pipes. Stainless steel, being an exceedingly durable and corrosion-resistant substance, is well-suited for deployment within plumbing systems. Furthermore, its non-reactive nature prevents the release of harmful chemicals into the water. Moreover, stainless steel pipes are effortlessly cleaned and maintained, thus minimizing the likelihood of bacterial proliferation and guaranteeing the safety and excellence of the drinking water.

- Q:What are the different types of stainless steel pipe supports?

- There are several different types of stainless steel pipe supports that are commonly used in various industries and applications. These include: 1. Adjustable pipe supports: These supports are designed to allow for easy adjustment of the pipe's position or height. They often feature a threaded rod or a telescoping design that can be extended or retracted to accommodate different pipe sizes or installation requirements. 2. Pipe hangers: These supports are used to suspend or hang pipes from overhead structures. They typically consist of a metal bracket or clamp that is attached to a beam or other structural element, and a hanging rod or strap that supports the weight of the pipe. 3. Pipe clamps: These supports are used to secure pipes to walls, floors, or other surfaces. They typically consist of a metal clamp that wraps around the pipe and is attached to the surface with screws or bolts. Pipe clamps can be adjustable or fixed, depending on the specific application. 4. Pipe saddles: These supports are used to cradle or support pipes on horizontal surfaces. They typically consist of a U-shaped metal bracket or saddle that is attached to the surface, and a cushioning material such as rubber or neoprene that helps to prevent damage to the pipe. 5. Pipe guides: These supports are used to guide or control the movement of pipes, particularly in applications where thermal expansion or contraction is a concern. They typically consist of a metal bracket or guide that is attached to a fixed structure, and a sliding or rolling element that allows the pipe to move while maintaining its alignment. Each type of stainless steel pipe support has its own specific advantages and is designed to meet different installation requirements. The choice of support will depend on factors such as the pipe material, size, weight, and the specific needs of the application.

- Q:Can stainless steel pipes be insulated with polystyrene?

- Yes, stainless steel pipes can be insulated with polystyrene. Polystyrene is a commonly used insulation material due to its thermal properties and ability to resist moisture. It can effectively reduce heat transfer and prevent condensation on the surface of the pipe. However, it is important to ensure that the polystyrene insulation is properly sealed and protected to avoid any degradation or damage to the stainless steel pipe.

- Q:Can stainless steel pipes be used for underground water supply lines?

- Yes, stainless steel pipes can be used for underground water supply lines. Stainless steel is highly resistant to corrosion, making it a suitable choice for underground applications where the pipes may come in contact with soil and water. Additionally, stainless steel pipes have excellent strength and durability, ensuring long-lasting performance in underground water supply systems.

- Q:Can stainless steel pipes be used for geothermal systems?

- Yes, stainless steel pipes can be used for geothermal systems. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for the harsh conditions of a geothermal system. Geothermal systems involve the transfer of heat from the earth's core to the surface, which often requires the circulation of hot water or steam. Stainless steel pipes can effectively handle the high temperatures and pressure associated with geothermal systems without corroding or degrading over time. Additionally, stainless steel is resistant to scaling and mineral build-up, which can be common in geothermal systems. Overall, the use of stainless steel pipes ensures the longevity and efficiency of geothermal systems.

- Q:Can stainless steel pipes be used for marine applications?

- Indeed, stainless steel pipes possess the capability to be utilized in marine applications. Renowned for its ability to resist corrosion, stainless steel emerges as an optimal substance to employ within marine surroundings, perpetually exposed to saltwater and elevated humidity levels. By being resistant to both rust and corrosion, stainless steel pipes guarantee their robustness and enduring nature when employed in marine applications. In the marine industry, they find extensive usage for a multitude of purposes, including piping systems, exhaust systems, and structural components. Furthermore, stainless steel pipes exhibit the capacity to endure extreme temperatures and pressures, rendering them suitable for the arduous conditions frequently encountered in marine applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

316 round stainless steel bar price for china manufacture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords