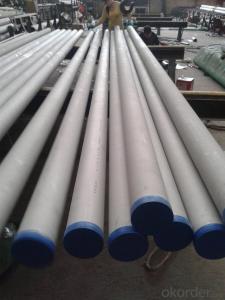

Stainless steel tube; high quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | JIS,AISI,ASTM,GB,DIN,CE | Place of Origin: | Guangdong China (Mainland) | Brand Name: | QX |

| Model Number: | 201/202/304/316/316L/430 | Type: | Welded | Steel Grade: | 300 Series |

| Application: | Decoration,construction, upholstery | Certification: | ISO | Welding Line Type: | ERW |

| Thickness: | 0.3mm to 3.0mm | Outer Diameter: | 9.53mm to 159mm | Polish: | Satin,Bright or Mirror |

| Grade: | 201,202,301,304,316,316l,430 ect. | Length: | In gernal 5.8m/6m or as customer request | Process method: | Hot rolled |

| Test: | Squash test, water pressure test,extended test,crystal rot test etc. | Production Standard: | ASTM A554 | Materials: | SUS 304, 201, 316, 316L,430 ect |

| OD tolerance: | + / - 0.15mm | Thickness tolerance: | +/- 10% | Length tolerance: | +/- 10mm |

Packaging & Delivery

| Packaging Detail: | Every tube is sleeved in plastic bag individually, and then several tubes are packed by weaving bag, which is seaworthy. Or 50kg/bundle, 500kg/bundle.We can pack as clients' requirement. |

| Delivery Detail: | 25 - 35 days for a full container. |

Specifications

Stainless Steel Pipe:

1.201,202,301,304,316L,430,etc

2.OD:6mm-159mm

3.Thickness:0.25mm-3.5mm

4.Finish:Mirror,Satin,Hairline

- Q:Can stainless steel pipes be used for automotive applications?

- Yes, stainless steel pipes can be used for automotive applications. Stainless steel is a highly durable material that offers excellent resistance to corrosion and heat. This makes it an ideal choice for automotive applications where pipes may be exposed to harsh environmental conditions, such as high temperatures, moisture, and road salt. Stainless steel pipes are commonly used in exhaust systems, fuel lines, and other components in automobiles. They provide superior strength and longevity compared to other materials, ensuring a longer lifespan for automotive parts and reducing the need for frequent replacements. Additionally, stainless steel pipes offer good aesthetic appeal and can be easily fabricated to meet specific design requirements for automotive applications.

- Q:What is the difference between 304J6 and 316J6 stainless steel pipes?

- The composition and properties of 304J6 and 316J6 stainless steel pipes are the main factors that differentiate them. 304J6 stainless steel is a variation of the widely used 304 stainless steel with low carbon content. It consists of approximately 18% chromium and 8% nickel, providing excellent corrosion resistance and durability. This grade finds application in various fields such as food processing, chemical processing, and architecture. On the other hand, 316J6 stainless steel is an austenitic grade known for its superior corrosion resistance compared to 304J6. It contains about 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The inclusion of molybdenum enhances its ability to withstand pitting and crevice corrosion in chloride environments, making it suitable for marine and coastal applications. Regarding mechanical properties, both grades exhibit satisfactory strength and toughness. However, due to its alloy composition, 316J6 stainless steel typically possesses higher tensile strength and hardness. In terms of price, 316J6 stainless steel pipes generally carry a higher price tag than 304J6 due to the increased cost of molybdenum. Consequently, the choice between the two grades depends on the specific requirements of the intended application and the desired level of corrosion resistance.

- Q:What are the different types of stainless steel pipe caps?

- There are various types of stainless steel pipe caps, including threaded caps, socket weld caps, butt weld caps, and compression caps.

- Q:What is the yield strength of stainless steel pipes?

- The yield strength of stainless steel pipes varies depending on the specific grade and composition of the stainless steel. However, stainless steel pipes generally have yield strengths ranging from 30,000 to 100,000 pounds per square inch (psi). It is important to note that the yield strength represents the point at which the material begins to deform permanently under applied stress. Therefore, it is crucial to choose the appropriate grade and thickness of stainless steel pipe based on the intended application and the specific mechanical properties required.

- Q:What is the difference between 347 and 316 stainless steel pipes?

- The main difference between 347 and 316 stainless steel pipes lies in their composition and intended use. 347 stainless steel pipes contain a higher percentage of niobium, which gives it improved high-temperature stability and resistance to sensitization. This makes it ideal for applications where the pipes will be exposed to high temperatures, such as in heat exchangers, furnace parts, and chemical processing equipment. The addition of niobium also enhances the resistance to intergranular corrosion. On the other hand, 316 stainless steel pipes are composed of molybdenum, which provides increased resistance to corrosion and pitting. This makes it suitable for applications involving exposure to harsh chemicals, saltwater, and other corrosive environments. It is commonly used in industries such as marine, pharmaceutical, and food processing. In terms of mechanical properties, both grades have excellent strength and corrosion resistance. However, due to the higher nickel content in 347 stainless steel, it is generally more expensive than 316 stainless steel. Overall, the choice between 347 and 316 stainless steel pipes depends on the specific requirements of the application. If high-temperature stability and resistance to sensitization are crucial, 347 stainless steel pipes would be the preferred choice. If corrosion resistance is the primary concern, especially in harsh environments, 316 stainless steel pipes would be more suitable.

- Q:How do you prevent corrosion in stainless steel pipes?

- To prevent corrosion in stainless steel pipes, there are a few measures that can be taken. Firstly, it is important to ensure that the stainless steel pipes are made from a high-quality grade of stainless steel. Different grades of stainless steel have varying levels of resistance to corrosion, so selecting the appropriate grade for the specific application is crucial. Secondly, regular cleaning and maintenance of the stainless steel pipes is essential. This involves removing any dirt, debris, or contaminants that can potentially cause corrosion. Cleaning can be done using mild soap or detergent, followed by rinsing with clean water and drying the pipes thoroughly. Moreover, it is advisable to avoid using abrasive cleaners or scrubbers that can scratch the surface of the stainless steel pipes, as this can create small crevices where corrosion can occur. Instead, soft cloth or sponge should be used for cleaning. Additionally, it is essential to protect stainless steel pipes from exposure to corrosive substances or environments. This can be achieved by applying a protective coating or using a corrosion-resistant paint on the pipes. This barrier will prevent direct contact between the stainless steel and corrosive substances, reducing the risk of corrosion. Furthermore, maintaining proper water chemistry is important for preventing corrosion in stainless steel pipes used for plumbing applications. Monitoring and controlling the pH level, hardness, and alkalinity of the water can help minimize the corrosive effects on the pipes. Lastly, ensuring proper installation and design of stainless steel pipes is crucial. This includes avoiding tight bends or sharp corners, which can trap moisture and lead to corrosion. Proper insulation and ventilation should also be considered to prevent condensation and subsequent corrosion. By following these preventive measures, corrosion in stainless steel pipes can be significantly reduced, ensuring their longevity and optimal performance.

- Q:What are the common corrosion issues with stainless steel pipes?

- There are a few common corrosion issues that can occur with stainless steel pipes. One of the most common is called pitting corrosion, which is characterized by small pits or holes that form on the surface of the pipe. Pitting corrosion is often caused by exposure to chloride ions, which can come from substances like saltwater or certain types of cleaning agents. Another common corrosion issue is crevice corrosion, which occurs in the narrow gaps or crevices between the pipe and other surfaces. These gaps can trap moisture or other corrosive substances, leading to localized corrosion. Crevice corrosion is often seen in areas where the pipe is joined or in areas with poor ventilation. Stress corrosion cracking is another common problem with stainless steel pipes. It occurs when the material is exposed to a combination of tensile stress and a corrosive environment. This can cause cracks to develop in the pipe, which can lead to leaks or structural failure. Finally, galvanic corrosion is a common issue when stainless steel pipes are in contact with other metals. When two different types of metals are in contact in the presence of an electrolyte, such as water, a galvanic cell can form and cause corrosion. To prevent this, it is important to use appropriate insulation or isolation techniques when connecting stainless steel pipes to other metals. Overall, while stainless steel is known for its corrosion resistance, it is not completely immune to corrosion. Understanding these common corrosion issues and taking preventive measures can help ensure the longevity and reliability of stainless steel pipes.

- Q:How do you protect stainless steel pipes from external damage?

- To ensure the protection of stainless steel pipes from external damage, there are several steps that can be taken: 1. Applying a protective coating: To shield the stainless steel pipes from moisture, chemicals, and physical harm, consider utilizing a protective coating such as paint or epoxy. Select the coating based on the specific environment and potential risks in order to maximize protection. 2. Installation of pipe supports: Preventing excessive movement and vibration is crucial in avoiding damage over time. Properly install pipe supports using brackets, clamps, or hangers to securely hold the pipes in place and minimize the risk of external impacts causing harm. 3. Implementation of corrosion prevention measures: Although stainless steel pipes are resistant to corrosion, certain environments can still pose a threat. Regularly inspect the pipes for signs of corrosion and address any issues promptly. Utilize corrosion inhibitors or cathodic protection techniques to further safeguard the pipes from external damage. 4. Usage of protective guards or covers: In areas where the pipes are vulnerable to potential impacts or physical harm, the installation of protective guards or covers can provide an additional layer of defense. These guards can be made from materials like plastic or rubber and can be easily installed or removed as needed. 5. Implementation of proper handling and storage procedures: During transportation or storage, it is crucial to handle stainless steel pipes with care. Avoid dropping or dragging them and make sure they are stored in a clean, dry, and well-ventilated area to prevent moisture buildup and potential damage. By adhering to these measures, the lifespan of stainless steel pipes can be significantly prolonged, ensuring their functionality and protection against external damage.

- Q:Can stainless steel pipes be used for chemical reactors?

- Indeed, chemical reactors can utilize stainless steel pipes. Stainless steel emerges as a favored selection for chemical reactors primarily because of its remarkable corrosion resistance properties. It exhibits an exceptional ability to resist chemical reactions and endure the severe conditions and corrosiveness associated with numerous chemicals employed in industrial procedures. Furthermore, stainless steel showcases remarkable strength and durability, rendering it appropriate for managing high-pressure and high-temperature scenarios frequently encountered in chemical reactors. Moreover, stainless steel can be effortlessly cleaned and maintained, a critical aspect in preserving the purity and integrity of the chemicals being treated. All in all, stainless steel pipes prove to be a dependable and effective option for chemical reactors.

- Q:Are stainless steel pipes suitable for architectural applications?

- Yes, stainless steel pipes are suitable for architectural applications. Stainless steel is a highly durable and corrosion-resistant material that can withstand harsh environmental conditions, making it ideal for architectural projects. It is commonly used in structural applications such as handrails, guardrails, and balustrades due to its strength and aesthetic appeal. Stainless steel pipes are also favored for their versatility, as they can be easily shaped and welded to create unique designs and structures. Additionally, stainless steel pipes offer low maintenance requirements and can be polished to a high shine, enhancing the overall aesthetics of architectural projects. Overall, stainless steel pipes are an excellent choice for architectural applications due to their durability, corrosion resistance, versatility, and aesthetic appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless steel tube; high quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords