Titan Geogrid

Titan Geogrid Related Searches

Geogrid Tbl Tenax Geogrid Geogrid Machine Geogrid Tensar Geostar Geogrid Miragrid Geogrid Terragrid Geogrid Tx 130 Geogrid Asphalt Geogrid Tencate Geogrid Geogrid Layer Geogrid Road Hanes Geogrid Tensar Ux Geogrid Universal Geogrid Plastic Geogrid Alliance Geogrid Geogrid Construction Best Geogrid Geogrid Energy Geogrid Walls Keystone Geogrid Ads Geogrid Gravel Geogrid Triax Geogrid Tensar Tx 130 Geogrid Geogrid Textile Synthetic Geogrid Geogrid Maps Geogrid ChinaTitan Geogrid Supplier & Manufacturer from China

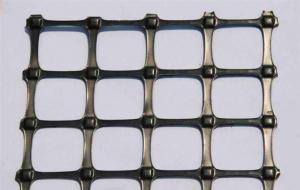

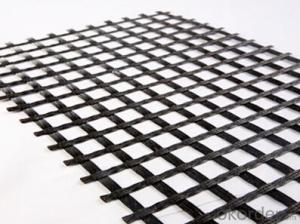

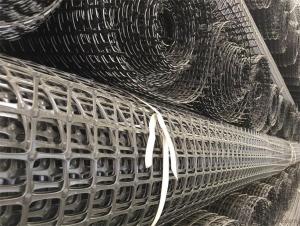

Titan Geogrid is a high-performance geosynthetic product designed to provide reinforcement and stabilization for various civil engineering applications. These products are engineered to enhance the load-bearing capacity of soil, reduce settlement, and improve overall stability in projects such as road construction, slope reinforcement, and retaining walls. The unique properties of Titan Geogrid make it an ideal solution for a wide range of construction and geotechnical challenges, offering increased durability and performance compared to traditional methods.In various construction and geotechnical projects, Titan Geogrid plays a crucial role in enhancing the structural integrity and longevity of the infrastructure. By incorporating this geosynthetic material into the design, engineers can expect improved load distribution, reduced maintenance costs, and a more sustainable solution for soil reinforcement. The versatility of Titan Geogrid allows it to be used in a multitude of scenarios, from highway and railway construction to coastal protection and landfill liners, making it an invaluable asset in the field of civil engineering.

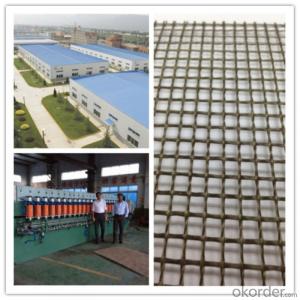

Okorder.com is a leading wholesale supplier of Titan Geogrid, boasting a vast inventory of this high-quality geosynthetic material. As a reputable distributor, Okorder.com ensures that customers have access to the latest innovations in geogrid technology, providing them with the necessary resources to tackle complex projects with confidence. With a commitment to customer satisfaction and a focus on delivering top-tier products, Okorder.com stands as a reliable source for those in need of Titan Geogrid for their construction and geotechnical endeavors.

Hot Products