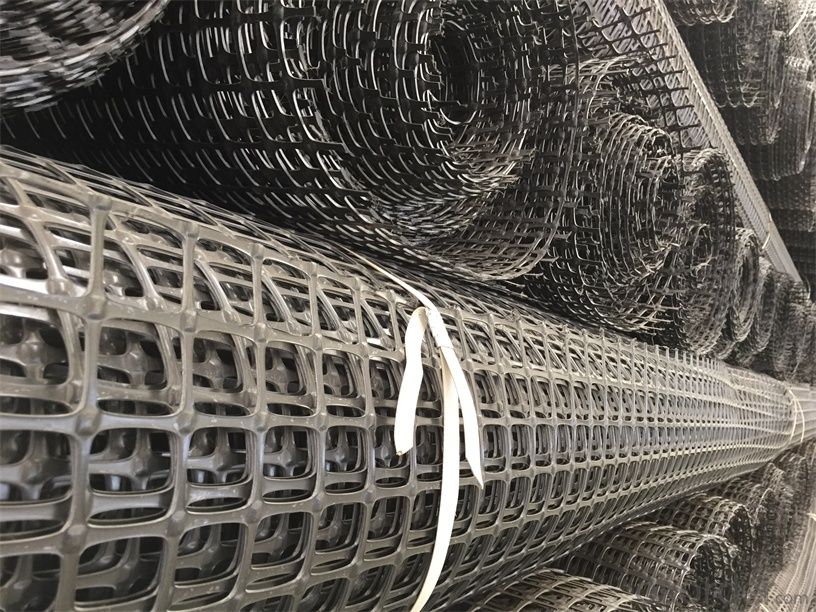

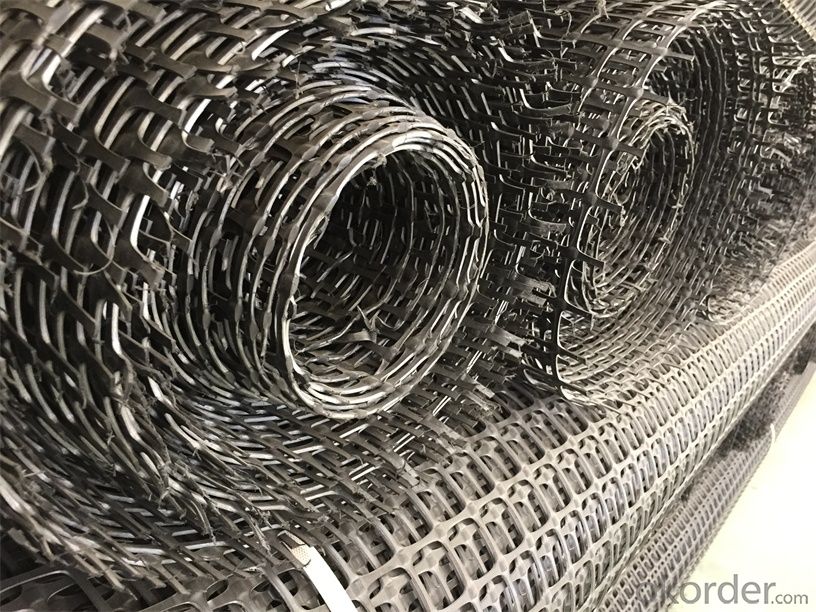

Geogrid Manufacutrer with Volume Production

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q:How do geogrids improve the performance of reinforced soil slopes?

- Geogrids improve the performance of reinforced soil slopes by providing additional stability and enhancing soil reinforcement. They act as a reinforcement material, distributing the loads more evenly and reducing the potential for soil erosion and slope failure. Additionally, geogrids increase the shear strength of the soil, prevent lateral movement, and improve the overall structural integrity of the slope.

- Q:Geogrid width mean?

- Width is the width of Geogrid

- Q:How do geogrids improve the performance of geosynthetic drainage systems?

- Geogrids improve the performance of geosynthetic drainage systems by providing structural support and enhancing load distribution. They prevent soil erosion and lateral movement, increasing the stability and longevity of the drainage system. Additionally, geogrids improve the overall drainage capacity by promoting water flow and preventing clogging, ensuring effective water removal from the soil.

- Q:Are there any limitations or disadvantages of using geogrids?

- Yes, there are some limitations and disadvantages of using geogrids. 1. Cost: Geogrids can be relatively expensive compared to other soil reinforcement methods. The cost of materials and installation can sometimes be prohibitive, especially for large-scale projects. 2. Limited Applications: Geogrids are not suitable for all types of soil conditions. They are most effective in granular soils, but their performance in cohesive soils or unstable slopes may be limited. 3. Installation Challenges: Proper installation of geogrids requires specific expertise and equipment. If not installed correctly, their effectiveness can be reduced, leading to potential failure or performance issues. 4. Longevity: The long-term durability of geogrids can vary depending on factors such as exposure to environmental conditions, chemical degradation, and mechanical damage. In some cases, they may require regular maintenance or replacement to ensure continued effectiveness. 5. Compatibility: Geogrids may not always be compatible with certain construction materials or methods. It is important to consider their compatibility with other materials used in the project to avoid any adverse effects on performance. Despite these limitations, geogrids are still widely used in various geotechnical applications due to their ability to improve soil stability and enhance the performance of structures.

- Q:History of geotechnical materials

- Geotextiles have the following three series:A needle nonwoven geotextile, the specification of 100g/m2-600g/m2 between any choice, the main raw materials is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture method, the main purpose is to: slopeprotection River, sea, Lake embankment, land reclamation, flood control engineering, dock lock, is an effective way to maintain and prevent the piping the filter to the soil.Two, non-woven cloth and PE membrane composite geotextiles, specifications have a membrane cloth, a cloth film two, maximum width of 4.2 meters is the main raw material to use acupuncture non-woven polyester staple fiber, PE film by composite, is mainly used for seepage control, railway, highway, tunnel, subway, airport, etc. engineering.Three, non-woven and woven composite geotextiles, non-woven fabric and polypropylene filament woven fabric, non-woven and plastic woven composite, suitable for foundation reinforcement, adjust the permeability coefficient of the basic engineering facilities.

- Q:Can geogrids be used in reinforcement of concrete structures?

- Yes, geogrids can be used in the reinforcement of concrete structures. Geogrids are commonly used as a reinforcing material in civil engineering projects, including the reinforcement of concrete structures such as retaining walls, bridge abutments, and road pavements. They help to distribute and enhance the load-bearing capacity of the concrete, improve its stability, and reduce the risk of cracking or structural failure.

- Q:Plastic two-way geogrid hole 4 cm thick, 1 mm wire width of 4 mm

- So I can give you a good price

- Q:What is the role of geogrid?

- The geogrid in the highway is mainly used for soft foundation treatment, subgrade reinforcement, slope protection, abutment reinforcement, wing walls, retaining walls, isolation and reinforced soil engineering, highway, railway,.1, abutment approach, wharf, dams, slag field in soft soil foundation reinforcement, retaining wall and road surface crack engineering.2, in areas such as railway use of geogrid can avoid premature Railway on soft ground settlement and damage, 3 generation of geogrid used in embankment, dam, - River, canal, sea levee, reservoir reinforcement and other water conservancy projects 4, geogrid reinforced foundation can greatly improve the airport runway the carrying capacity, ensure aircraft safety 5, geogrid can be used for landfill site processing, power plant, ash dam project, coal mine, metallurgy, greening, fence and other areas 6, building structure of soft foundation reinforcement, improve the whole foundation Bearing capacity

- Q:What are some common standards and specifications for geogrids?

- Some common standards and specifications for geogrids include the ASTM D6637 standard for uniaxial geogrids, the ASTM D6917 standard for biaxial geogrids, and the ISO 10318 standard for geosynthetics. These standards outline requirements for geogrid properties such as tensile strength, elongation, aperture size, and durability, ensuring quality and consistency in geogrid products.

- Q:What are the long-term maintenance requirements for geogrid-reinforced structures?

- The long-term maintenance requirements for geogrid-reinforced structures typically involve periodic inspections to ensure the integrity of the structure and the geogrid. These inspections may include visual assessments, measurements, and testing to detect any signs of damage, settlement, or deterioration. Additionally, regular cleaning and removal of debris from the structure is necessary to prevent blockages or potential damage. Overall, proper maintenance and timely repairs are essential for the longevity and performance of geogrid-reinforced structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geogrid Manufacutrer with Volume Production

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords