Titan Geogrids Bitumen Coated Geogrid for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

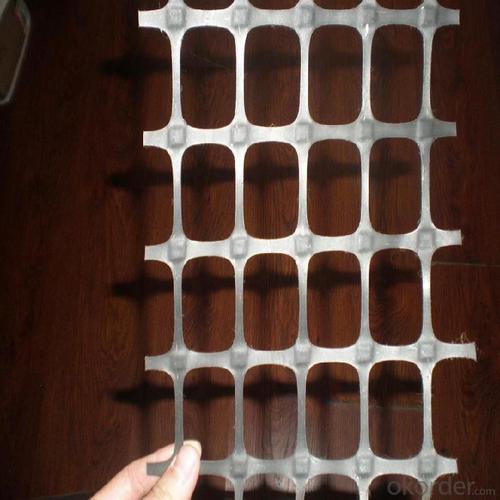

Structure of Bitumen Coated Geogrid

Bitumen Coated Geogrid is to select high quality enhanced non-alkali fiberglass yarn,and it uses foreign advanced warp knitting woven to become the base materials.Using the warp knitting oriented structure to make full use of the fabric yam strength and improve its mechanical properties ,so it makes good tensile strength ,tearing strength and resistance to creep properties of modified asphalt,and through high quality coating is handled and become planar finely materials.

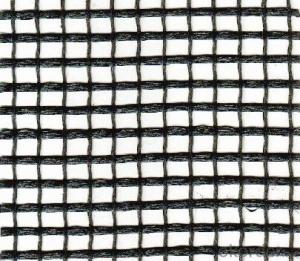

Main Features of the Fiberglass Geogrid

fiberglass geogrids

Corrosion resistance, no long-term creep, long life span.

- Tensile strength:MD/CD:30 ~ 150kn/m.

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Bitumen Coated Geogrid Images

Bitumen Coated Geogrid Specification

Roadbed reinforcement of road and railway,crack prevention,increase of roadbed strength;

Reinforcement and stabilization of riverside,embankment and side slope;

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

Reinforcement of the surface of road and bridge

Preventing and controlling the cracking caused by new and old combination and uneven settlement.

Road extension.

Reinforcement of soft soil foundation and overall strength of roadbed

| Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | ||

| Mesh size(mm) | 25.4×25.4or12.5×12.5 | ||||||

| Breaking strength≥(KN/m) | Warpdirection | 30 | 50 | 80 | 100 | 120 | |

| Across warp | 30 | 50 | 80 | 100 | 120 | ||

| Elongation at break≤(%) | Warp direction | 3 | |||||

| Across warp | 3 | ||||||

| Elasticity modulus(GPA) | 67 | ||||||

| Thermal tolerance() | -100~280 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Biaxial Plastic Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geogrids resistant to seismic forces?

- Yes, geogrids are resistant to seismic forces. Geogrids are made of strong materials like polyester or polypropylene, which provide high tensile strength and resistance to stretching. These characteristics allow geogrids to effectively withstand and distribute seismic forces, making them a reliable solution for reinforcing soil in areas prone to earthquakes.

- Q: What are the limitations of geogrids?

- Geogrids have a few limitations. Firstly, they are not suitable for all types of soil and terrain conditions. They are most effective in soils with good particle interlock and cohesion. Secondly, geogrids are not effective in situations where there is high water flow or erosion potential as they do not provide sufficient protection against these forces. Additionally, geogrids may have limited strength in certain applications, such as heavy load-bearing scenarios, and may require additional reinforcement. Lastly, the installation and maintenance of geogrids can be complex and costly, requiring skilled labor and regular inspections to ensure proper functioning.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in clayey soils?

- Geogrids improve the performance of mechanically stabilized slopes in clayey soils by providing reinforcement and enhancing the overall stability of the slope. The geogrids act as a tension element, distributing the tensile forces and reducing the potential for slope failure. They increase the shear strength of the soil, preventing excessive movement and reducing the risk of slope deformation. Additionally, geogrids help to control the lateral spreading of the soil by confining it within the reinforced zone, thereby improving the overall performance and longevity of the slope in clayey soils.

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically include factors such as soil type, slope angle, required strength, and design considerations. It is important to follow manufacturer guidelines and industry standards to ensure proper installation, including techniques for anchoring, overlap, and tensioning. Additionally, proper site preparation, including soil compaction and leveling, is crucial for a successful geogrid installation.

- Q: How do geogrids enhance the stability of steep slopes?

- Geogrids enhance the stability of steep slopes by providing reinforcement and confinement to the soil. They are typically installed within the slope, creating a strong interlocking network that distributes loads and prevents soil movement. This reinforcement helps to increase the overall strength of the slope, reducing the risk of slope failure and improving stability.

- Q: Are geogrids effective in reducing differential settlement?

- Yes, geogrids are effective in reducing differential settlement. Geogrids are engineered materials that provide reinforcement and stabilization to soil. By distributing loads more evenly and improving soil strength, geogrids help mitigate differential settlement, which occurs when different areas of soil settle at different rates.

- Q: How do geogrids help in reducing the risk of soil liquefaction?

- Geogrids help in reducing the risk of soil liquefaction by providing reinforcement to the soil, improving its stability and reducing its susceptibility to liquefaction. These geosynthetic materials are typically installed within the soil to distribute and restrain the lateral forces exerted during an earthquake or other dynamic loading events. By enhancing the soil's shear strength and increasing its resistance to deformation, geogrids help to mitigate the potential for liquefaction and the associated risks such as ground settlement and structural damage.

- Q: Are geogrids suitable for use in ground reinforcement for agricultural facilities?

- Yes, geogrids are suitable for use in ground reinforcement for agricultural facilities. Geogrids provide effective soil stabilization, preventing erosion and enhancing load-bearing capacities. They are especially beneficial in areas with heavy machinery or high foot traffic, offering long-term durability and improved agricultural operations.

- Q: What is the recommended geogrid connection method for specific applications?

- The recommended geogrid connection method for specific applications depends on several factors such as the type of geogrid, soil conditions, and project requirements. Some common geogrid connection methods include using mechanical connectors, overlapping and sewing the geogrid panels, or using adhesive bonding. It is important to consult with a geotechnical engineer or follow the manufacturer's guidelines to determine the most suitable connection method for a specific application.

- Q: Classification of plastic geogrid

- 2, to highlight the advantages of geogrid is deformation under sustained loading (creep) tendency is very small, creep strength is much better than other materials geogrid, plays an important role in improving the service life of the project.3, the mesh grille and soil interlock and interlock function, constitute an efficient stress transfer mechanism, so that local load can be quickly and effectively spread to a large area of soil, to reduce the local failure stress, improve the service life of engineering.Three, the application of one-way plastic geogrid:Unidirectional plastic geogrid is a kind of high strength geosynthetics. Widely used in dams, tunnels, docks, highways, railways, construction and other fields.

Send your message to us

Titan Geogrids Bitumen Coated Geogrid for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords