Ceiling Light Shade Holder

Ceiling Light Shade Holder Related Searches

Best Inverter For Solar System Led Light For Chandelier Decorative Ceiling Plate For Light Fixture Inverter For 5kw Solar System Parts For Light Fixtures Transformer For Light Fixture Decorative Lights For Ceiling Lights For Kitchen Ceiling Ceiling Brackets For Lights Hanging Ceiling Chairs For BedroomsHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Aluminum Bar Stock For SaleCeiling Light Shade Holder Supplier & Manufacturer from China

Okorder.com is a professional Ceiling Light Shade Holder supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Ceiling Light Shade Holder firm in China.Hot Products

FAQ

- PC sun panels and color steel plate how to bond

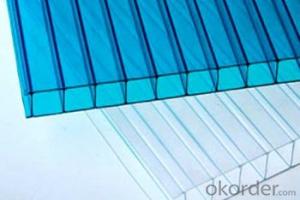

- The use of sealant at the junction, with self-tapping screws fixed on the purlins. Transparent sun panels and insulation color plates are two different roofs. The sun panels are mainly made of PC / PET / PMMA / PP. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly. Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate. Color steel plate is divided into veneer, Caigang composite board, floor board and so on. Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs.

- Company pc sunshine board how to solve the problem

- Two layers of waterproof treatment: sun board endurance board joints with a wide aluminum alloy bar, in the pressure below the bonding of special waterproof tape, and then use a good quality neutral sealant on both sides of the pressure to play the thickness of 5 mm width 5 -8 mm silicone.

- What is the difference between a hollow board and a sunboard?

- But both have a lighting function, which sunshine board lighting performance and weather better and the lighting board is better acid and alkali resistance, not easy to be acid and alkali corrosion, the production process is not the same, the sun is a co-extruded, the production process Slightly more complicated. The lighting plate is connected to the tapping screw and must have a cover plate. Sun plate cold and heat deformation is large, easy to be self-tapping nail cut, so the sun plate in the self-tapping nail should open a larger hole. In the installation of lighting panels to consider the expansion of the lighting board.

- PC board greenhouses pc board generally use thick? What is the price? What about the current market price? Is the sun board a PC board?

- In addition, most manufacturers will use recycled materials, basically low-cost-based, no guarantee. I suggest you choose, these manufacturers do not ask, boring, save that money is not enough after the repair it So the election board when a principle: want to do the performance of the project, with a good Bayer plate, basically no trouble; want to earn more money or low bid winning project, with the back of the board, anyway, never mind.

- What are the differences between plastic endurance boards and sun panels?

- Color: transparent, blue, green, creamy, brown, gray.

- Pc sun panels and frp lighting board what are the two differences

- 1. Material is a PC, one is FRP commonly known as glass fiber high performance UV resin; 2.PC is not resistant to corrosion, FRP is a good anti-corrosion performance; 3.PC sun board is hollow board, light transmission is better, FRP is usually a solid plate, usually semi-translucent state; 4. High-quality PC sunshine board surface has UV coating, anti-ultraviolet, anti-yellowing, such as Cortron sunshine board, and high-quality FRP surface is covered with thin film, such as red wave FRP lighting tile. 5.PC warranty period up to 10 years or so, FRP warranty up to 25 years;

- What is the difference between sun panels and lighting panels?

- Material composition description Xining PC sun panels are made of polycarbonate on the surface of a layer of 50um UV UV layer, hollow structure extrusion molding of high-performance lighting materials. Is the most excellent performance of engineering plastics, which has a light, flame retardant, high impact strength, high transmittance, high stability, easy to bend and other characteristics. And is an energy-saving, environmentally friendly materials. Is the preferred material for making lighting materials. FRP lighting board is glass fiber reinforced polyester (FRP lighting board), commonly known as FRP, also known as transparent tile, which mainly by the film, unsaturated resin and glass fiber composition. Frp main material is unsaturated resin, its high strength, flammable, the resin itself is easy to decompose above 50 ℃, poor stability. Resin is chemically synthesized, using styrene solvent, toxic.

- PC sunshine board, what material, what kind of good

- If you want to use their own cost-effective relatively high we can choose 10mm quality better, this kind of sunshine board in the normal situation is to allow people not often walk in the above. But for 8mm or 6mm sun panels, if people go in the above or want to shelf life for a long time there may be a safe use of hidden dangers.