Monolithic Refractories Zirconia Slide Gate Nozzle for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

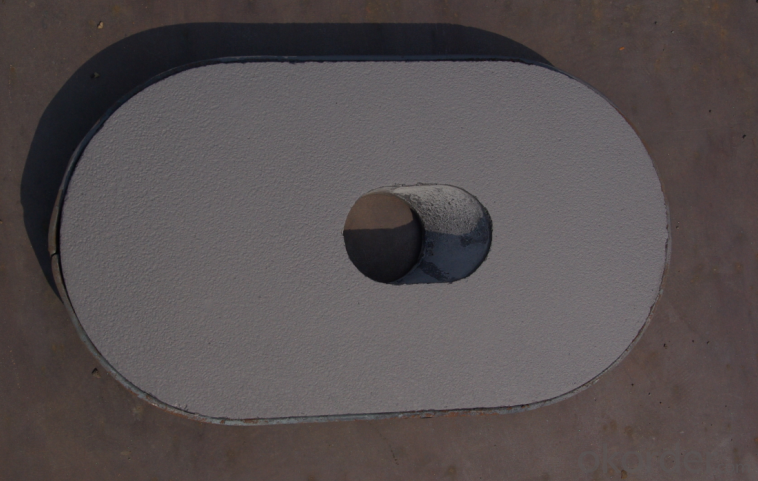

Zirconia Slide Gate Nozzle for Steel Industry

Slide gate plate widely used in large ladle, middle ladle and small ladle to fit for high quality steel casting.

Slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Burnt Slide gate

Item B60,B50,C40type | Al-C Slide Gate | Al-Zr-C Slide Gate | ||||||

AlC-70 | AlC -75 | AlC -80 | AlC-85 | AlC -86 | AlZrC -70 | AlZrC-75 | AlZrC -77 | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 | 70 | 75 | 77 |

C+SiC,% | 7 | 7 | 5 | 5 | 4 | 7 | 7 | 7 |

ZrO2,% | - | - | - | - | - | 6 | 6 | 2.5 |

A.P.,% max | 10 | 10 | 10 | 10 | 7 | 10 | 10 | 10 |

B.D.,g/cm3 | 2.8 | 2.9 | 2.9 | 3.0 | 2.95 | 3.00 | 3.05 | 2.90 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 | 110 | 115 | 100 |

Unburned compound AlC Slide gate

Item B60,B50,C40type | Al-C Slide Gate | ||||

AlC-70A | AlC-75A | AlC-80A | AlC-85A | AlC-86A | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 |

C,% | 7 | 7 | 5 | 5 | 4 |

A.P.,% max | 10 | 10 | 8 | 10 | 7 |

B.D. g/cm3 min | 2.8 | 2.9 | 3.0 | 3.0 | 2.95 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 |

zirconium core :

Item | ZN- 65 | ZN- 70 | ZN- 75 | ZN- 80 | ZN- 85 | ZN- 90 | ZN- 93A | ZN- 93B | ZN- 93C | ZN- 93D | ZN- 95A | ZN- 95B | ZN- 96 |

ZrO2(%) | ≥65 | ≥70 | ≥75 | ≥80 | ≥85 | ≥90 | ≥93 | ≥93 | ≥93 | ≥93 | ≥95 | ≥95 | ≥96 |

Bulk density (g/cm3) | ≥3.8 | ≥3.8 | ≥3.9 | ≥4.0 | ≥4.1 | ≥4.3 | ≥5.1 | ≥4.9 | ≥4.7 | ≥4.4 | ≥4.6 | ≥5.2 | ≥5.2 |

Apparent Porosity(%) | ≤23 | ≤22 | ≤22 | ≤20 | ≤20 | ≤20 | ≤13 | ≤15 | ≤18 | ≤20 | ≤20 | ≤9 | ≤5.6 |

Thermal shock resistance (cycles)(1100℃,water cooling) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >8 | >10 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are monolithic refractories inspected and tested for quality assurance?

- Monolithic refractories are inspected and tested for quality assurance through various methods. Visual inspections are conducted to check for any visible defects such as cracks, spalling, or other physical damages. In addition, non-destructive testing techniques like ultrasonic testing and X-ray inspection are used to detect any internal flaws or inconsistencies in the refractory material. Furthermore, mechanical testing such as compression and flexural strength tests are performed to evaluate the mechanical properties of the monolithic refractories. These inspections and tests ensure that the refractories meet the required quality standards and can withstand the harsh operating conditions they are designed for.

- Q: How do monolithic refractories perform in ladle lining applications in the iron and steel industry?

- Due to their excellent performance and durability, monolithic refractories are extensively utilized in ladle lining applications within the iron and steel industry. These refractories, which consist of a single material composition, offer numerous advantages over traditional brick linings. One significant benefit of employing monolithic refractories in ladle lining applications is their exceptional resistance to thermal shock. Ladles in the iron and steel industry experience extreme temperature fluctuations during the steelmaking process, including the pouring of molten metal and subsequent cooling. To guarantee the integrity of the ladle lining, monolithic refractories are specifically designed to endure these rapid temperature changes without cracking or spalling. In addition to their thermal shock resistance, monolithic refractories also demonstrate excellent resistance to chemical attack. The lining materials of ladles in the iron and steel industry are exposed to highly corrosive molten metal and slag, which can degrade over time. Nevertheless, monolithic refractories are formulated with high-quality raw materials that provide exceptional chemical stability, preventing the erosion and penetration of corrosive substances. Moreover, monolithic refractories offer superior mechanical strength in comparison to traditional brick linings. This is particularly crucial in ladle lining applications, as the lining must withstand the weight of the molten metal and the mechanical stresses associated with ladle handling and transportation. Monolithic refractories possess excellent load-bearing capabilities, ensuring the structural integrity of the ladle lining even under heavy loads. Another advantage of monolithic refractories is their ease of installation. Unlike brick linings, which require meticulous bricklaying, monolithic refractories can be installed using various techniques, such as gunning or casting. This allows for faster and more efficient lining repairs or replacements, reducing downtime during ladle maintenance. Consequently, iron and steel manufacturers can achieve increased productivity and cost savings. In conclusion, monolithic refractories perform exceptionally well in ladle lining applications within the iron and steel industry. Their resistance to thermal shock and chemical attack, superior mechanical strength, and ease of installation make them an ideal choice for ensuring the longevity and reliability of ladles in steelmaking operations.

- Q: What are the common failure mechanisms of monolithic refractories in the iron and steel industry?

- Some common failure mechanisms of monolithic refractories in the iron and steel industry include thermal spalling, erosion, chemical attack, and mechanical damage. Thermal spalling occurs due to rapid temperature changes, causing the refractory material to crack and break. Erosion occurs when hot gases or molten metal wear away the refractory lining. Chemical attack refers to the corrosive action of slag or other chemicals on the refractory material. Mechanical damage may occur due to physical impacts or stresses, leading to cracks and fractures in the refractory lining.

- Q: What are the considerations for repairing and relining monolithic refractories?

- When repairing and relining monolithic refractories, there are several key considerations that need to be taken into account. First and foremost, it is crucial to assess the extent of the damage or deterioration in order to determine the appropriate repair method. Factors such as the type of refractory material, the operating conditions, and the expected service life must be considered. Additionally, it is essential to select the right refractory material for the repair or relining process. This involves evaluating the temperature range, chemical resistance, thermal conductivity, and mechanical properties of the refractory material to ensure it is compatible with the specific application. Another important consideration is the proper preparation of the surface before applying the repair material. This may involve removing any loose or damaged refractory, cleaning the surface thoroughly, and creating a suitable bonding surface to ensure optimal adhesion. Furthermore, the application technique and curing process of the repair material should be carefully followed to achieve the desired performance and durability. This may involve proper mixing, application thickness, drying time, and temperature control. Lastly, it is crucial to conduct regular inspections and maintenance to identify any signs of deterioration or damage early on. This proactive approach will help prevent major repairs or relining in the future and prolong the overall lifespan of the monolithic refractories.

- Q: What are the main factors affecting the corrosion resistance of monolithic refractories?

- The corrosion resistance of monolithic refractories can be influenced by several important factors. To begin with, the refractory material's chemical composition plays a significant role. Refractories with high levels of silica (SiO2) generally exhibit greater resistance to corrosion due to silica's excellent resistance to acidic environments. Conversely, refractories with high alumina (Al2O3) content are more resistant to basic environments. Furthermore, the microstructure of the refractory material is crucial. A compact and well-bonded microstructure offers better corrosion resistance compared to materials with a porous structure. The presence of pores or cracks can allow corrosive substances to penetrate and attack the refractory, leading to its degradation. The temperature at which the refractory is exposed also affects its corrosion resistance. Higher temperatures can accelerate the corrosion process by promoting more aggressive chemical reactions. Additionally, thermal cycling, which involves subjecting the refractory to repeated heating and cooling, can create thermal stresses that contribute to material degradation. The type and concentration of corrosive agents present in the environment also impact the corrosion resistance of monolithic refractories. Different corrosive agents have varying levels of reactivity with refractory materials. For instance, acidic substances like sulfuric acid or hydrochloric acid can cause significant corrosion, whereas alkaline substances like calcium oxide can lead to a more gradual degradation. Moreover, mechanical stress applied to the refractory can influence its corrosion resistance. Mechanical vibrations, abrasion, or impact can weaken the refractory structure, making it more susceptible to corrosion. Lastly, the manufacturing and installation process can affect the corrosion resistance of monolithic refractories. Factors such as proper mixing, curing, and drying techniques can contribute to the development of a more resistant refractory structure. In conclusion, the corrosion resistance of monolithic refractories is influenced by factors including chemical composition, microstructure, temperature, presence of corrosive agents, mechanical stress, and manufacturing/installation processes. Understanding and managing these factors are crucial in selecting and maintaining the most suitable refractory material for a specific application.

- Q: How do monolithic refractories withstand the thermal cycling in coke oven applications?

- Monolithic refractories are able to withstand the thermal cycling in coke oven applications due to their high thermal shock resistance and low thermal conductivity. They have a unique composition and structure that allows them to expand and contract without cracking or spalling under extreme temperature fluctuations. Additionally, their dense and homogeneous structure minimizes heat transfer, allowing them to maintain their integrity and strength even in the harsh conditions of coke oven operations.

- Q: What are the common testing methods used to evaluate the performance of monolithic refractories?

- The common testing methods used to evaluate the performance of monolithic refractories include thermal conductivity testing, hot modulus of rupture testing, abrasion resistance testing, thermal shock resistance testing, and corrosion resistance testing.

- Q: What are some common applications of monolithic refractories in the iron and steel industry?

- Monolithic refractories are widely used in the iron and steel industry due to their superior performance and versatility. Some common applications of monolithic refractories in this industry include: 1. Blast Furnace: Monolithic refractories are used in the lining of blast furnaces to withstand high temperatures and chemical reactions. They help in maintaining the structural integrity of the furnace and provide insulation against heat loss. 2. Ladle Lining: Monolithic refractories are used to line ladles, which are used for transferring molten iron or steel from the blast furnace to the steelmaking process. These refractories provide excellent resistance to thermal shock and erosion caused by the aggressive molten metal. 3. Tundish Lining: Tundish is an intermediate vessel used to distribute molten steel to multiple casting molds. Monolithic refractories are employed in the tundish lining to ensure proper thermal insulation and prevent contamination of the steel during casting. 4. Electric Arc Furnace (EAF): Monolithic refractories are used in the lining of EAFs to withstand the extreme temperatures and chemical reactions involved in the steelmaking process. They provide excellent resistance to high heat and erosion caused by the molten metal and slag. 5. Induction Furnace: Induction furnaces are used for melting and refining metals. Monolithic refractories are used in the lining of induction furnaces to provide insulation and protect the furnace structure from the high temperatures and chemical reactions occurring during the melting process. 6. Continuous Casting: Monolithic refractories are used in the lining of continuous casting machines to ensure smooth and consistent casting of molten steel. They provide excellent resistance to high temperatures, thermal shock, and erosion caused by the molten metal and slag. Overall, monolithic refractories play a crucial role in the iron and steel industry by providing durability, thermal insulation, and resistance to chemical reactions, thereby enhancing the overall efficiency and productivity of the manufacturing process.

- Q: Can monolithic refractories be used for lining iron and steel ladles during casting and pouring?

- Yes, monolithic refractories can be used for lining iron and steel ladles during casting and pouring. Monolithic refractories are versatile and can withstand high temperatures, making them suitable for such applications. They provide excellent thermal insulation and chemical resistance, ensuring the integrity of the ladle lining and preventing contamination of the molten metal during the casting process.

- Q: How do monolithic refractories perform in electric arc furnace roof applications?

- Due to their unique properties and characteristics, monolithic refractories are extremely effective when used in electric arc furnace (EAF) roof applications. Comprised of a single, solid material, these refractories offer several advantages specific to this application. To begin with, monolithic refractories provide exceptional thermal insulation, a critical factor in EAF roof applications. Traditional brick refractories can suffer structural damage from the intense heat generated in the furnace. However, monolithic refractories possess a higher resistance to thermal shock, reducing the risk of cracking and spalling. This ensures that they maintain their integrity and insulation properties even under extreme temperature conditions. Furthermore, monolithic refractories exhibit high strength and abrasion resistance, guaranteeing their durability and longevity in EAF roof applications. The roof of an electric arc furnace is subjected to harsh conditions, including the impact of scrap materials and the erosive effects of molten metal and slag. Monolithic refractories are specifically designed to withstand these challenges, offering superior resistance to mechanical wear and erosion. Another advantage of monolithic refractories lies in their ease of installation. Unlike traditional brick refractories, which necessitate time-consuming and complex installation processes, monolithic refractories can be applied rapidly and efficiently. They can be cast, gunned, or sprayed onto the roof surface, adapting to any shape or contour. Consequently, installation or repair downtime is reduced significantly. Moreover, monolithic refractories contribute to increased energy efficiency in EAF roof applications. Their superior insulation properties minimize heat loss, resulting in reduced energy consumption and cost savings. This is particularly crucial for electric arc furnaces, as their efficiency and productivity heavily rely on maintaining high temperatures for metal melting and processing. Any heat loss can have a significant impact on these factors. In conclusion, monolithic refractories are highly suitable for electric arc furnace roof applications due to their exceptional thermal insulation, strength, abrasion resistance, ease of installation, and energy efficiency. These refractories offer significant advantages over traditional brick refractories, ensuring optimal performance and extended service life in the demanding environment of an electric arc furnace.

Send your message to us

Monolithic Refractories Zirconia Slide Gate Nozzle for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords