Monolithic Refractories High Temperature Ladle Sliding Gate Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

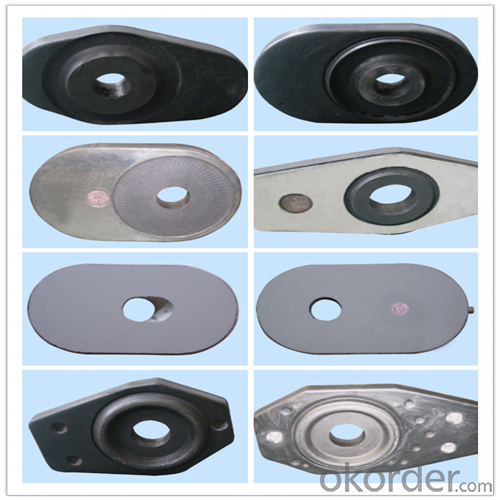

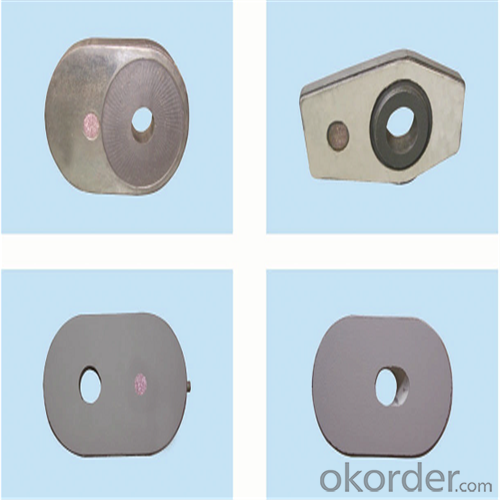

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

Other Products

About us

Sample is on your request.

Welcome to visit our factory~

- Q: How do monolithic refractories withstand the chemical attacks in copper smelting applications?

- Due to their unique properties and composition, monolithic refractories are capable of enduring chemical attacks in copper smelting applications. These refractories are specifically engineered to resist the harsh and corrosive environment found in copper smelting processes. To begin with, monolithic refractories are crafted from high-quality materials such as alumina, silica, and magnesia. These materials possess high melting points and chemical stability. Carefully selected, they are able to withstand the corrosive effects of copper smelting, including the presence of sulfur compounds and acidic gases. The refractory's composition also includes various additives and bonding agents that enhance its resistance to chemical attacks. In addition, monolithic refractories exhibit exceptional thermal shock resistance. This means they can withstand rapid temperature changes without cracking or spalling. In copper smelting applications, where extreme temperatures are involved, this refractory quality is crucial in preventing the formation of cracks and ensuring long-term performance. Furthermore, monolithic refractories possess a dense and compact structure. This structure serves as an effective barrier against the infiltration of molten copper and other corrosive substances. By preventing the penetration of chemical attacks, the refractory lining's durability and longevity are ensured. Moreover, monolithic refractories offer superior erosion resistance. This is particularly important in copper smelting applications, where high-velocity gases and flows of molten metal can cause erosion of the refractory lining. The refractory's erosion resistance prevents the degradation of the lining and maintains its structural integrity. In conclusion, monolithic refractories are specially designed to withstand the chemical attacks encountered in copper smelting applications. Through the use of high-quality materials, the incorporation of additives, and the possession of excellent thermal shock resistance, density, and erosion resistance, these refractories provide a reliable and durable lining that can endure the harsh conditions of copper smelting processes.

- Q: How are monolithic refractories different from traditional brick refractories?

- Monolithic refractories differ from traditional brick refractories in several ways. Firstly, monolithic refractories are made from a single, homogeneous material, while traditional brick refractories are made from individual bricks that are assembled together. This difference in construction allows monolithic refractories to have a more uniform and consistent structure, which can enhance their performance and durability. Secondly, monolithic refractories are typically easier to install compared to traditional brick refractories. Since they are made from a single material, they can be poured or sprayed into place, eliminating the need for precise bricklaying and mortar application. This ease of installation saves time and labor during construction or repair projects. Additionally, monolithic refractories often have superior thermal shock resistance compared to traditional brick refractories. The homogeneous structure of monolithic refractories allows them to expand and contract more uniformly under thermal stress, reducing the risk of cracking and failure. This makes monolithic refractories more suitable for applications where rapid temperature changes occur, such as in furnaces or kilns. Furthermore, monolithic refractories can offer better resistance to chemical attacks and erosion. Traditional brick refractories may have joints and gaps between bricks, which can become vulnerable to chemical reactions or erosion over time. Monolithic refractories, on the other hand, have a seamless structure that minimizes the risk of chemical penetration and erosion, enhancing their longevity and performance. Overall, monolithic refractories offer advantages in terms of uniformity, ease of installation, thermal shock resistance, and chemical resistance compared to traditional brick refractories. These differences make monolithic refractories a preferred choice for many industrial applications where high temperatures and harsh environments are present.

- Q: What are the quality control measures for monolithic refractories in the iron and steel industry?

- In the iron and steel industry, the quality control measures for monolithic refractories are essential to ensure the efficiency and safety of the production process. These measures involve various inspections and tests throughout the manufacturing and installation stages. Firstly, the raw materials used for monolithic refractories undergo rigorous testing. This includes analyzing the chemical composition, particle size distribution, and impurity content. These tests ensure that the ingredients meet the required specifications and are suitable for the intended application. During the production process, quality control measures focus on monitoring the mixing and blending of the materials. This ensures a homogeneous mixture and avoids any inconsistencies in the final product. The density and viscosity of the refractory castables or plastics are also checked to maintain the desired physical properties. Once the monolithic refractories are manufactured, they undergo several tests to evaluate their performance characteristics. These tests can include determining the cold crushing strength, modulus of rupture, and thermal conductivity. These properties are critical to ensure the refractories can withstand the extreme temperatures and mechanical stress present in the iron and steel industry. In addition to laboratory testing, quality control measures involve on-site inspections during installation. This includes verifying the correct application techniques, such as proper vibration, curing, and drying procedures. It is important to ensure that the monolithic refractories are applied correctly to achieve optimal performance and longevity. Furthermore, regular sampling and monitoring of the refractories' performance during operation are carried out. This allows for the detection of any signs of degradation or wear, enabling proactive maintenance and replacement before any significant issues arise. Overall, the quality control measures for monolithic refractories in the iron and steel industry involve comprehensive testing, monitoring, and inspection procedures. These measures aim to guarantee the reliability, durability, and efficiency of the refractories, ultimately contributing to the smooth operation of the iron and steel production processes.

- Q: What are the main factors affecting the thermal expansion of monolithic refractories?

- The main factors affecting the thermal expansion of monolithic refractories include the type of refractory material, the temperature range, the chemical composition, and the physical structure of the refractory. Firstly, the type of refractory material plays a significant role in its thermal expansion behavior. Different types of refractories, such as alumina-based, silica-based, and magnesia-based refractories, have varying coefficients of thermal expansion (CTE). For example, alumina-based refractories generally have a lower CTE compared to silica-based refractories. Therefore, the choice of refractory material can greatly influence its thermal expansion characteristics. Secondly, the temperature range at which the refractory is exposed affects its thermal expansion. As the temperature increases, the refractory material expands due to the thermal energy absorbed. However, different refractories have different temperature-dependent expansion behaviors. Some refractories may have a linear or near-linear expansion with temperature, while others may exhibit non-linear or step-wise expansion. The temperature range of operation is an important consideration in determining the suitability of a refractory for a particular application. The chemical composition of the refractory also affects its thermal expansion. The presence of different chemical elements and compounds in the refractory material can influence its expansion behavior. For example, the addition of certain oxides, such as magnesia or zirconia, can alter the CTE of the refractory. Similarly, impurities or variations in the chemical composition can introduce differences in expansion characteristics among refractories of the same type. Lastly, the physical structure of the refractory, including its porosity, density, and microstructure, can affect thermal expansion. The presence of open or closed pores within the refractory can affect its ability to expand uniformly under thermal stress. The density of the refractory also plays a role, as denser refractories tend to have lower thermal expansion. Additionally, the microstructure, including grain size and orientation, can influence the overall expansion behavior of the refractory. In conclusion, the main factors affecting the thermal expansion of monolithic refractories include the type of refractory material, temperature range, chemical composition, and physical structure. Understanding these factors is essential in selecting the appropriate refractory for a specific application to ensure optimal performance and durability.

- Q: How do monolithic refractories perform in aluminum holding furnace applications?

- Monolithic refractories perform exceptionally well in aluminum holding furnace applications due to their high thermal conductivity, excellent resistance to thermal shock, and superior mechanical strength. They can withstand the extreme temperatures and harsh chemical environments found in these furnaces, ensuring long-lasting and efficient operations. Additionally, monolithic refractories offer easy installation and maintenance, making them a preferred choice in aluminum holding furnace applications.

- Q: How do monolithic refractories contribute to the overall efficiency of ladles and tundishes?

- There are several ways in which monolithic refractories greatly improve the effectiveness of ladles and tundishes. Initially, the exceptional thermal insulation properties of monolithic refractories are well-known. By lining the ladles and tundishes with these refractories, heat loss is minimized, resulting in reduced energy consumption and improved thermal efficiency. This insulation capability also helps in maintaining a consistent temperature within the ladles and tundishes, which is vital for the proper casting and solidification of molten metal. Furthermore, monolithic refractories provide excellent resistance to thermal shocks and chemical corrosion. Ladles and tundishes are exposed to extreme temperatures and harsh chemical environments due to their contact with molten metal and various fluxes or additives. The use of monolithic refractories ensures that the ladles and tundishes have a longer lifespan by preventing cracking, spalling, or erosion caused by these harsh conditions. As a result, there is less downtime for maintenance and replacement, leading to increased overall efficiency. Moreover, the flexibility and ease of installation of monolithic refractories contribute to the efficiency of ladles and tundishes. Unlike traditional brick lining, monolithic refractories can be easily shaped and installed in different sizes and forms. This versatility allows for better customization and optimization of ladles and tundishes. This adaptability helps to improve the flow dynamics of molten metal, reducing turbulence, and enhancing the overall casting process efficiency. In conclusion, monolithic refractories significantly enhance the efficiency of ladles and tundishes through their exceptional thermal insulation properties, resistance to thermal shocks and chemical corrosion, and flexibility in installation. By reducing heat loss, extending the lifespan, and optimizing the casting process, monolithic refractories make a significant contribution to the overall efficiency and productivity of ladles and tundishes in the metal industry.

- Q: What are the different types of monolithic refractories used in the iron and steel industry?

- In the iron and steel industry, several types of monolithic refractories are used due to their excellent thermal resistance, high strength, and durability. These refractories are essential in various applications to withstand extreme temperatures and harsh conditions. The different types of monolithic refractories commonly used in the iron and steel industry include: 1. Castables: These are precast refractory materials that are mixed with water to form a slurry, which is then poured or cast into molds. Castables are widely used in iron and steel industries for lining ladles, tundishes, and other furnaces due to their high strength and excellent resistance to thermal shock. 2. Ramming Mass: Ramming mass is a refractory material that is used for lining induction furnaces and other melting units. It is made up of refractory aggregates, binders, and additives. Ramming mass is applied by ramming or tamping it into place, forming a dense lining that can withstand high temperatures and chemical attacks. 3. Gunning Mix: Gunning mix is a refractory material that is applied using a pneumatic gunning machine. It is used for repairing or lining various areas of furnaces and is particularly useful for hot repairs. Gunning mix consists of refractory aggregates, binders, and additives, which are sprayed onto the lining surface and then compacted. 4. Plastic Refractories: Plastic refractories are mixtures of refractory aggregates and binders that have a high plasticity and can be easily molded or shaped. They are used for repairing or patching refractory linings in iron and steel industries. Plastic refractories are typically applied by hand or using a trowel and are suitable for both hot and cold applications. 5. Mortars: Refractory mortars are used for jointing or repairing refractory bricks or other monolithic refractories. They are made up of refractory powders, binders, and water. Mortars provide excellent adhesion between bricks or monolithic materials, ensuring a strong and durable lining in furnaces, ladles, and other high-temperature equipment. These different types of monolithic refractories play a vital role in the iron and steel industry by providing reliable and long-lasting linings, ensuring efficient operations and minimizing downtime.

- Q: How do monolithic refractories resist chemical attack from molten metals and slags?

- Monolithic refractories resist chemical attack from molten metals and slags due to their chemical composition and structure. They are typically designed with high levels of resistance to corrosion and erosion, making them suitable for harsh environments. Additionally, they have low porosity, which reduces the penetration of molten metals and slags into the refractory material. The presence of certain additives and bonding agents further enhances their chemical resistance, preventing reactions between the refractory and the molten substances. Overall, monolithic refractories offer a strong barrier against chemical attack, ensuring their durability and longevity in such demanding conditions.

- Q: Can monolithic refractories be used for the lining of ladle refining furnaces and VOD converters?

- Indeed, ladle refining furnaces and VOD converters can benefit from the utilization of monolithic refractories. These refractories, which consist of a single, uniform material, can be molded and installed in various settings, particularly those involving extreme temperatures such as ladle refining furnaces and VOD converters. The advantage of monolithic refractories lies in their simplicity of application and repair. They can be either cast or gunned in place, offering flexibility in terms of lining design and installation. The lining of ladle refining furnaces and VOD converters requires materials capable of withstanding high temperatures, chemical reactions, and mechanical stresses. Monolithic refractories are well-suited for these demanding applications due to their exceptional resistance to thermal shock and chemical attack. In the case of ladle refining furnaces, monolithic refractories are used to line the vessel in which molten metal is contained and processed. By doing so, these refractories help to maintain the desired temperature and safeguard the ladle from the corrosive effects of both molten metal and slag. Additionally, they serve as insulation to minimize heat loss and enhance energy efficiency. VOD converters, on the other hand, are employed in the steelmaking process to reduce the carbon content of molten steel. Monolithic refractories play a crucial role in lining the converter's vessel and ensuring the maintenance of the required temperature for the decarburization reaction. Furthermore, they provide protection against the corrosive impact of molten metal and slag, thereby guaranteeing the converter's durability and performance. To summarize, monolithic refractories possess outstanding characteristics that make them an excellent choice for lining ladle refining furnaces and VOD converters. Their versatility, ease of installation, and ability to withstand high temperatures and chemical attack render them perfectly suited for these critical applications within the steel industry.

- Q: How do monolithic refractories provide thermal insulation in the iron and steel industry?

- Monolithic refractories play a crucial role in providing thermal insulation in the iron and steel industry. These refractories are commonly used to line the furnaces and other high-temperature equipment used in the production processes. One way monolithic refractories provide thermal insulation is by their ability to withstand high temperatures without degrading or melting. They are designed to have high heat resistance, which allows them to be used in environments where temperatures can reach several thousand degrees Celsius. By withstanding these extreme temperatures, the refractories prevent the transfer of heat to the surrounding structure, thus providing insulation. Another way monolithic refractories provide thermal insulation is through their low thermal conductivity. These materials have a low thermal conductivity, meaning they are not efficient in conducting heat. Instead, they trap the heat within their structure and minimize its transfer to the surrounding equipment or environment. This characteristic helps to maintain the temperature inside the furnaces and other high-temperature equipment, allowing for efficient and controlled metal production. Furthermore, monolithic refractories can be applied as a thick lining layer, which creates an additional barrier between the high-temperature environment and the surrounding equipment. The thickness of the refractory lining helps to minimize heat transfer and acts as a buffer, reducing the impact of high temperatures on the structural integrity of the equipment. In addition to providing thermal insulation, monolithic refractories also offer excellent resistance to chemical attack and mechanical wear, which are common challenges in the iron and steel industry. This resistance ensures the longevity of the refractory lining, allowing for consistent and reliable insulation over time. Overall, monolithic refractories provide thermal insulation in the iron and steel industry through their high-temperature resistance, low thermal conductivity, thick lining layer, and resistance to chemical attack and mechanical wear. These properties contribute to maintaining the desired temperature inside the equipment and protecting the surrounding structure from the intense heat generated during metal production processes.

Send your message to us

Monolithic Refractories High Temperature Ladle Sliding Gate Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords