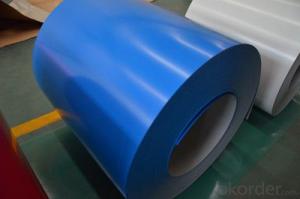

Z14 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z14 BMP Prepainted Rolled Steel Coil for Construction

Description of Z14 BMP Prepainted Rolled Steel Coil for Construction

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z14 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z14 BMP PPGI Prepainted Rolled Steel Coil for Construction

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Z14 BMP Prepainted Rolled Steel Coil for Construction

Product | Z14 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z14 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: I understand that damascus sword steel was made by folding the strip of steele double , reheating, hammering, folding again and so forth hundreds of times. Was this the same or very nearly the same techmique the japs used making the sword blades the samari swords?(forgive the misspelling)

- The samari swords are made by folding to make many many alternating layers of different steel compositions. Damascus swords were made differently. The steel was heated and forged (like samari swords) but it was not folded. The patterns produced are due to the micro macro-structure of the steel alloy and the way the steel is forged. Fake Damascus steel knives and gun barrels and other items have been made by pattern welding (forge cladding steels with different compositions together) and then folding and forging with some tricks. google damascus steel and you will find lots of info. hope this helps

- Q: How are steel coils used in the production of metal fixtures?

- Steel coils are an essential component in the production of metal fixtures. These coils, which are typically made from carbon steel, are used as the primary raw material to manufacture a wide range of metal fixtures. The steel coils are first uncoiled and then cut into sheets of the desired size and thickness. These sheets serve as the base material for different types of metal fixtures, including brackets, hinges, handles, and other structural components. Once the sheets are cut, they undergo various forming processes such as bending, stamping, or rolling. These processes help shape the steel sheets into the specific design required for the metal fixture. For instance, bending may be used to create brackets or angles, while stamping can be used to form intricate patterns or shapes. After the forming processes, the steel sheets are often subjected to welding or joining techniques to assemble multiple components of the metal fixture. Welding ensures that the various parts are securely attached, providing strength and durability to the final product. Furthermore, steel coils also play a crucial role in enhancing the appearance and longevity of metal fixtures. They can be coated or treated with protective layers, such as galvanized or powder coatings, to prevent corrosion and provide a polished finish. These coatings ensure that the metal fixtures can withstand environmental factors and extend their lifespan. In summary, steel coils are an integral part of the production process for metal fixtures. They are transformed into sheets, which are then shaped, joined, and coated to create a wide range of functional and aesthetically pleasing metal fixtures used in various industries.

- Q: like building steel beams. i'm pretty sure with a sawzall.

- I am going to take a slightly different approach. Once the structural steel is manufactured and then brought to the fabricator, not much heat is applied to the steel. It is normally punched, sheared or whatever buy the use of a lot of heat on it is normally not allowed due to the change in the properties of the steel. Once in the field to be erected, the cutting or welding on it are held to absolute minimums and most of the time not allowed at all.

- Q: How are steel coils used in the manufacturing of exhaust systems?

- Steel coils are used in the manufacturing of exhaust systems as they provide the necessary material for forming and shaping various components such as pipes, mufflers, and catalytic converters. These coils are typically processed through cutting, bending, and welding techniques to create the required shapes and sizes for the different parts of an exhaust system.

- Q: What are the main factors to consider when selecting a steel coil supplier?

- When selecting a steel coil supplier, the main factors to consider include the supplier's reputation and reliability, the quality of their products, their pricing and payment terms, their delivery options and lead times, their customer service and support, as well as their ability to meet your specific requirements and specifications.

- Q: How do steel coils contribute to the circular economy?

- The recyclability and reusability of steel coils make them valuable contributors to the circular economy. The main goal of the circular economy is to minimize waste and promote the continuous use of resources, and steel coils align perfectly with this concept. To begin with, steel coils are manufactured using recycled steel, which reduces the need for extracting raw materials and the associated negative environmental effects. By utilizing recycled steel, we can conserve natural resources and decrease energy consumption in the manufacturing process. This practice not only lowers carbon emissions but also decreases the overall ecological footprint. Furthermore, steel coils can be easily recycled once they reach the end of their lifespan. Steel has one of the highest recycling rates globally. When the coils are no longer in use, they can be collected, processed, and transformed into new steel products without losing their properties or quality. This closed-loop recycling system ensures that steel resources are continuously utilized, reducing the need for virgin steel production. In addition, steel coils support the circular economy by enabling the production of durable and long-lasting products. Steel is renowned for its strength and durability, making it ideal for various applications such as construction, automotive, and packaging. By using steel coils, we can manufacture products with extended lifespans, minimizing the need for frequent replacements and reducing waste generation. Moreover, steel coils can be reused multiple times before being recycled. They can be rewound, reshaped, or repurposed for different applications, thus extending their lifecycle and reducing the demand for new coils. This aspect of reusability contributes to resource efficiency and waste reduction. To summarize, steel coils play a significant role in the circular economy by being made from recycled steel, easily recyclable themselves, enabling the production of durable products, and promoting reuse. Their contribution helps close the loop in the steel industry, conserves natural resources, reduces waste generation, and minimizes environmental impact.

- Q: I don't know it is low alloy steel or high allow steel or medium carbon steel

- It is a high alloy steel. Look at all the elements in it's name for it's composition: 30% Chromium and Nickel 8% Molybdenum Sounds like a very tough stainless tool steel for cutting rock or something. Chromium and nickel arre the two elements they use to make stainless steel and molybdenum is used to make steel very hard and wear resistant

- Q: What are the common defects in steel coil finishes?

- There are several common defects that can occur in steel coil finishes. These defects can impact the appearance and functionality of the steel and may need to be addressed before the coil can be used or sold. 1. Coil breaks: Coil breaks are a common defect where the steel strip breaks during winding or unwinding. This defect can result in a discontinuity in the surface of the coil and can lead to further damage if not addressed. 2. Edge wave: Edge wave refers to a distortion or waviness at the edges of the steel coil. This defect can occur during the rolling or cooling process and can affect the flatness and uniformity of the coil. 3. Corrosion: Corrosion can occur on the surface of steel coils if they are not properly protected or stored. This can lead to rust and degradation of the steel, impacting its strength and appearance. 4. Streaks and stains: Streaks and stains can occur on the surface of steel coils due to improper cleaning or contamination during the production process. These defects can affect the aesthetic appearance of the steel and may need to be addressed before the coil can be used. 5. Scratches and dents: Scratches and dents can occur on the surface of steel coils during handling, transportation, or storage. These defects can impact the flatness and surface quality of the steel and may require repairs or adjustments. 6. Coating defects: If the steel coil has a coating or paint applied to it, several defects can occur. These include blistering, peeling, or uneven application of the coating, which can affect the durability and appearance of the steel. It is important to note that these defects can vary in severity and may require different methods of repair or mitigation. Regular inspections and quality control measures can help identify and address these defects before they become more significant issues.

- Q: What are the safety considerations when handling steel coils?

- When handling steel coils, it is important to consider safety measures to prevent accidents or injuries. Some key safety considerations include: 1. Proper training: All personnel involved in handling steel coils should receive adequate training to understand the risks associated with the task and learn proper handling techniques. 2. Personal protective equipment (PPE): Workers should wear appropriate PPE such as gloves, safety boots, and eye protection to protect against cuts, punctures, or other injuries. 3. Load capacity and stability: Ensuring that lifting equipment and machinery used for handling steel coils have the necessary load capacity and stability is crucial to prevent accidents or equipment failures. 4. Proper lifting techniques: Using correct lifting techniques, such as bending the knees and lifting with the legs rather than the back, helps to minimize the risk of strains or back injuries. 5. Secure storage: Steel coils should be stored in a secure and organized manner, with proper blocking, bracing, or racking systems in place to prevent them from shifting or falling. 6. Inspection and maintenance: Regular inspection of lifting equipment, hooks, slings, and other accessories is essential to identify any signs of wear or damage that could compromise safety. 7. Communication and coordination: Establishing clear communication protocols and coordination among workers involved in handling steel coils can help prevent accidents, especially in areas with limited visibility or restricted access. 8. Hazard identification and mitigation: Identifying potential hazards such as sharp edges, loose straps, or uneven surfaces, and taking appropriate measures to mitigate these risks, is vital to ensure safe handling practices. By considering these safety measures, the risk of accidents or injuries associated with handling steel coils can be significantly reduced.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws as they serve as the raw material for manufacturing the screws. The steel coils are unwound and fed into a machine that cuts and shapes the steel into the desired screw form. This process ensures that the screws are made from high-quality steel and have the necessary strength and durability.

Send your message to us

Z14 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords