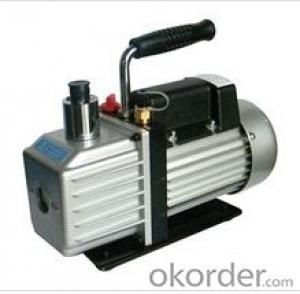

YHZKB-2XZ series rotary vane vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

2XZ-BSeries

1. High speed, Iow volume, light weight, equipped with noise reducer, low noise, less shake. Pump stop and oil returnprevention is equipped, so that pupm oil is prevented to get back to the pump once pump stopped working, which makes it easy to restart.2. Gas valve is installed in order to separate the vapor from the gas, when pumping gas mixed with vapor. The valve prohibited the entrance of the vapor, ensured the purity and prolonged the use of the pump oil.3. Vent is applied with oil fog capture mchine to eliminate oil fog when discharge the gas. Ol collecting equipment is installed around the oil sal, in order to preven oil leaking, and entironment pollution.Motor power:0.37~1.5KW,extract capacity2~15L/S,Limit vacuum:2×10-2Pa。

■List of performance |

| Unit | 2XZ-2B | 2XZ-4B | 2XZ-6B | 2XZ-8B | 2XZ-15B | |

off-gas quick result | L/S | 2 | 4 | 6 | 8 | 15 | |

limited pressure | Branch pressure (close gas) | Pa | 2×10-2 | 2×10-2 | 2×10-2 | 2×10-2 | 2×10-2 |

General pressure (close gas) | Pa | 6×10-1 | 6×10-1 | 6×10-1 | 6×10-1 | 6×10-1 | |

Branch pressure (open gas) | Pa | 6×10-1 | 6×10-1 | 6×10-1 | 6×10-1 | 6×10-1 | |

General pressuer (open gas) | Pa | 9×10-1 | 9×10-1 | 9×10-1 | 9×10-1 | 9×10-1 | |

Noise (close gas) | dB(A) | 60 | 60 | 65 | 70 | 70 | |

Working temperature | ℃ | 80 | 80 | 80 | 85 | 85 | |

electric machine | Voltage | V | 380/220 | 380/220 | 380/220 | 220/380 | 220/380 |

Power | Kw | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | |

Rotate speed | r/min | 1420 | 1420 | 1420 | 1400 | 1400 | |

Weight | Kg | 23 | 30 | 40 | 70 | 90 | |

Shape&size (L×W×H) | mm | 560×190×230 | 570×190×230 | 570×190×230 | 600×230×420 | 690×230×420 | |

- Q: Must the water pump in the tank be all soaked in water?

- Need a submersible pump in the water, but it is not entirely like this, I have to work for a long time no problem in water, but there is a problem you should pay attention to the water pump, at least in half, or stop when the smoke is not on water.

- Q: Troubleshooting of diaphragm pump

- The ratio of flow to water weight at a specific weight of --68F. 68F water has a specific gravity of 1Static suction head - the vertical distance from the liquid level to the central line of the pump. The pump shall be above the level of the liquid.Vapor pressure the pressure of all the steam on the free surface of the liquid. In any pump operating system, the operating pressure shall not be lower than the vapor pressure, otherwise the steam will be partially or completely cut off into the pump fluid. Viscosity - because of the presence of friction in the fluid, the property of viscosity gives the fluid resistance to flow.Water hammer action -Water hammer is a sudden power failure, or in the valve closed too fast, due to pressure, flow of inertia, produce water shock waves, like hammer hammer, so called water hammer. The force produced by the flow of water shock waves can sometimes be very large, thereby damaging the valves and pumps. Water hammer effect refers to the inside of the water pipe, the pipe wall is smooth, flow freely. When the opening of the valve suddenly closes, the flow of water to the valve and the tube wall, mainly the valve, will produce a pressure. As the pipe wall is smooth, the subsequent water flow in the role of inertia, the fastest reach the maximum and damage, which is the water conservancy "water hammer effect", that is, "positive water hammer.". This factor should be taken into consideration in the construction of water conservancy pipelines. On the contrary, the valve closed in a sudden opening, it will produce water hammer, called negative water hammer, but also a certain destructive power, but not the former big.. Causes and treatment methods of common failures of diaphragm pumps:

- Q: What are the characteristics of a pipe shield pump?

- Two, reverse circulation type of shielding pump, its bearings, lubrication, cooling and motor cooling fluid flow direction and the basic type is the opposite. The main characteristic of reverse circulation pump is that it is not easy to generate cavitation. It is suitable for conveying liquid which is easy to vaporize. Sometimes it is also called "easy to vaporize" type. Three, high temperature medium temperature of up to 450 degrees. The cooling water jacket is usually added outside the shielding motor, and a cooling sleeve is added to the outer circulation pipe to cool the high temperature circulating liquid to reduce the temperature of the motor and the bearing. In the case of less power, some manufacturers do not use cooling liquid, but the outside of the motor is equipped with fins and the special winding to adapt to the working conditions, the use of temperature generally can not exceed 400 degrees.

- Q: What's the meaning of the pump head in the water pump, please advise, thank you

- According to China Wikipedia network, the basic components of the water pump: motor, coupling, pump head (body) and chassis (horizontal).Pump is generally composed of pump body and pump head, in which the pump body refers to the spiral case, impeller, bearing, oil shell and sealing assembly, etc., the pump head refers to the impeller, bearings, oil ring and sealing rotating parts (including shaft), etc..

- Q: Operating procedures for measuring pumps

- 3, discharge pipeline unimpeded.4, the pipeline should meet the positive pressure head, that is, in high flow suction conditions work.5, check the direction of the pump, strictly prohibited reverse.6. Check the oil level in the crankcase compartment. For multi cylinder pumps, check that the oil level has reached the required level.7 、 pump motor static grounding is good, meet the requirements.

- Q: Is the centrifugal pump large or small?

- Centrifugal pump, the smaller the better the cavitation.1, centrifugal pump cavitation less, anti cavitation performance is better, the pump cavitation is called the necessary cavitation margin or pump inlet dynamic pressure drop, the smaller the better. Generally speaking, the pump cavitation is the need for cavitation, the pump inlet pipe said effective cavitation margin, that is, the device cavitation margin. For a given pump, at a given speed and flow rate required NPSH is called pump necessary NPSH, also called NPSH, is required to achieve the performance parameters of the pump cavitation, the internal flow and the centrifugal pump is composed of pump head itself, its physical meaning is that liquid drop in pump inlet pressure part degree, is to guarantee the pump cavitation does not occur, with surplus energy exceeds the vaporization pressure head at the inlet of the pump unit weight of liquid. The cavitation must be independent of the device parameters. It is only related to the parameters of the inlet of the pump. These parameters are determined by the geometric parameters at a given speed and flow.

- Q: Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- Different working conditions, our company does dry claw pump alone can also achieve the vacuum of 133 PA.

- Q: How can I buy a pump?

- 2, must meet the characteristics of the media requirementsFor the delivery of flammable, explosive, toxic or valuable medium pump, requiring reliable sealing shaft or the use of non leakage pump, such as magnetic drive pumps (without shaft seal, using isolated magnetic indirect drive).For the transmission of corrosive medium pumps, convection components are required to use corrosion-resistant materials, such as fluorine plastic corrosion resistant pump.For conveying pumps containing solid particles, wear resistance materials shall be adopted in convection parts, and clean liquid shall be used for shaft seal when necessary.

- Q: Pneumatic diaphragm pump compressed air pressure is 4 kg, the discharge pressure is how big?

- Pigment pressure is less than 0.4mpa,About 0.3. Go up.As the pump diaphragm is in the middle of a connecting rod, equivalent to the cylinder cavity, the pressure will be reduced; and because of the loss of pigment tube pressure will be reduced.

- Q: How accurate is the metering pump?

- In addition, when the oil supply is too large or the pipeline pressure rises unexpectedly, the volume of the liquid in the hydraulic chamber can be changed, thereby affecting the stability of the flow and reducing the metering accuracy of the pump. In order to solve the problem of how to stabilize the measurement accuracy of metering pump metering pump flow, how stable, the three valve device. The so-called actual refers to the combination of three functions including compensation, discharge and safety protection device or device supporting the hydraulic chamber, according to its action principle is different, is divided into automatic compensation and forced compensation two three valve device.

Send your message to us

YHZKB-2XZ series rotary vane vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords