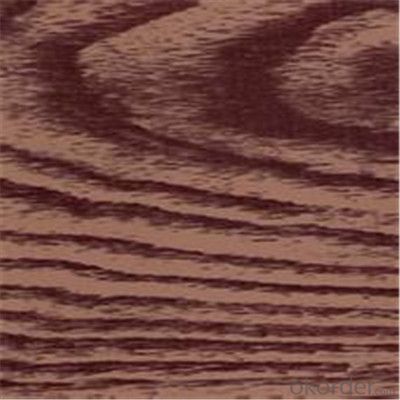

Wood Pattern Coated Galvanized PPGI Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Glove:

1. Zinc coating :40-180g( as required)

2. thickness:0.2-1.2mm

3. width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

4. coil id:508mm/610mm

5. coil weight: 4-10 MT(as required)

6. surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Festures of Glove:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc

Specifications of Glove:

Specifications | |

Name | buy wood grain design ppgi!bs approved printed ppgi!prime quality cr steel coil |

Full name | Galvanized ,Galvalume,Pre-paited galvanizing,Pre-paited galvalume |

Basic material | Cold Roll |

Color of the PPGI and PPGL | Any color in RAL |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Spangle | Normal / Min / Zero |

Thickness | 0.14mm-2.0mm |

Width | 750mm to 1250mm |

Images of Glove:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: How do steel coils contribute to the marine vessel construction industry?

- Steel coils are essential components in the marine vessel construction industry as they play a crucial role in the fabrication of various structural elements of ships and boats. These coils are typically made of high-quality steel and are used in a variety of ways to contribute to the construction and performance of marine vessels. Firstly, steel coils are utilized in the construction of the hull, which is the main body of the ship. The hull requires strong and durable materials to withstand the harsh conditions of the sea, including waves, corrosion, and impacts. Steel coils provide the necessary strength and integrity to the hull, ensuring the vessel's structural integrity and safety. Moreover, steel coils are also employed in the fabrication of decks, bulkheads, and other internal structures of marine vessels. These components are crucial for dividing the ship into compartments, providing stability, and supporting various equipment and machinery. Steel coils are known for their excellent tensile strength, which allows them to bear heavy loads and resist deformation, making them ideal for constructing these vital components. Additionally, steel coils are used in the construction of propulsion systems and other mechanical parts of marine vessels. These coils are often shaped and formed into specific components, such as shafts, gears, and propellers, which are critical for the vessel's propulsion and maneuverability. The high strength and durability of steel coils ensure the reliability and efficiency of these mechanical systems, enabling smooth navigation and operation of the vessel. Furthermore, steel coils contribute to the marine vessel construction industry by enhancing the overall safety and longevity of ships and boats. Steel is known for its resistance to corrosion, which is a significant concern in marine environments due to the presence of saltwater. By utilizing steel coils, marine vessels can withstand the corrosive effects of seawater, reducing the need for frequent maintenance and repair. This, in turn, improves the lifespan of the vessel and reduces the risk of accidents or failures at sea. In conclusion, steel coils are indispensable in the marine vessel construction industry. These coils provide the necessary strength, durability, and resistance to corrosion, ensuring the safety, performance, and longevity of ships and boats. From the construction of the hull to the fabrication of internal structures and mechanical components, steel coils play a vital role in every aspect of marine vessel construction.

- Q: Are steel coils used in construction?

- Yes, steel coils are commonly used in construction. They are widely utilized in various applications such as structural frameworks, roofing, flooring, and cladding systems. Steel coils provide strength, durability, and flexibility, making them an essential material for construction projects.

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Wood is made up of elements which are non-metals with a high electron affinity. Specifically, carbon, oxygen, hydrogen, and some nitrogen. Furthermore the covalent bond structure in wood means electrons are tightly bound and cannot move easily from atom to another. Not without adding a great deal of energy to the first. Steel is mostly iron, which is a metal. Metals have low electron affinity. The outer electrons in metals are bound very loosely, so that they can move from atom to atom using almost no energy. Metals tend to conduct electricity very easily.

- Q: Like 49ers. Pittsburgh have long history of steel industry?

- Yes, short and simple

- Q: How do steel coils contribute to energy efficiency in transportation?

- There are several ways in which steel coils help improve energy efficiency in transportation. To begin with, steel coils are lightweight and have a high strength-to-weight ratio. This means that they require less steel material to carry the same load compared to other materials like wood or concrete. As a result, the overall weight of the transport vehicle is reduced, leading to lower fuel consumption and emissions. Furthermore, steel coils are extremely durable and can withstand harsh transportation conditions. They are highly resistant to corrosion, impact, and fatigue, ensuring a longer lifespan for the transport vehicle. This durability reduces the need for frequent repairs or replacements, resulting in reduced energy consumption and material waste. Moreover, steel coils are easily handled and transported. Due to their compact and standardized size, they can be effortlessly loaded and unloaded from trucks, trains, or ships. This efficiency in handling reduces the time and energy required for loading and unloading operations, ultimately increasing overall transportation efficiency. Additionally, steel coils can be efficiently stacked and stored, maximizing the utilization of available space in transport vehicles. This reduces the number of trips needed to transport the same amount of goods, resulting in less energy consumption and lower transportation costs. Lastly, steel is a highly recyclable material. At the end of their life cycle, steel coils can be easily recycled and used to produce new steel products. This reduces the demand for raw materials and the energy required for manufacturing new products, thereby contributing to overall energy efficiency in transportation. In conclusion, steel coils play a crucial role in enhancing energy efficiency in transportation. Their lightweight, durable, easy-to-handle, and recyclable nature leads to decreased fuel consumption, lower emissions, reduced maintenance needs, efficient use of space, and minimized material waste. All of these factors contribute to a more sustainable and energy-efficient transportation system.

- Q: How are steel coils inspected for impact resistance?

- Steel coils are inspected for impact resistance through various methods including conducting visual inspections, performing non-destructive testing such as ultrasonic testing and magnetic particle inspection, and conducting drop tests to simulate real-life impact scenarios. These inspection techniques help ensure that the steel coils meet the required standards and can withstand potential impacts during transportation, handling, and usage.

- Q: What kind of insulation should be used in a steel building?

- Vinyl fiberglass insulation is getting popular with the steel building industry. The vinyl fiberglass insulation offers a shining look to the building and is resistant to dust as well as condensation. Effective ventilation inside the steel building can also help in preventing the condensation process inside the building. Besides, the building doors should be insulated effectively so as to minimize the heat loss. Be sure to seal all the door gaps in the building. All these steps are necessary to follow to get an effectively insulated steel building.

- Q: How are steel coils inspected for width variations?

- Steel coils are inspected for width variations using specialized equipment such as laser or optical sensors that measure the width of the coils at regular intervals. These sensors provide accurate and precise measurements, allowing inspectors to identify any variations in width across the length of the coil.

- Q: Are steel coils used in appliances manufacturing?

- Yes, steel coils are commonly used in the manufacturing of appliances. They serve as a key component in various appliances such as refrigerators, washing machines, and dryers, providing structural strength and stability to the overall product.

Send your message to us

Wood Pattern Coated Galvanized PPGI Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords